Mould Component

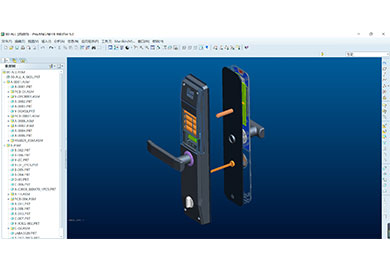

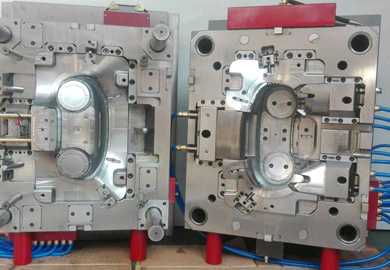

GM-TECH,a injection molding companies in china, has been manufacturing tools for injection molding of plastics for various industries for more than 10 years. We are also experienced in automotive, electrical and home appliance industries but also manufacture moulds for other industries requiring plastic injection moulds. We are able to offer you complete services in this area, from design of the moulds, over their high-quality manufacturing in own tool shop.

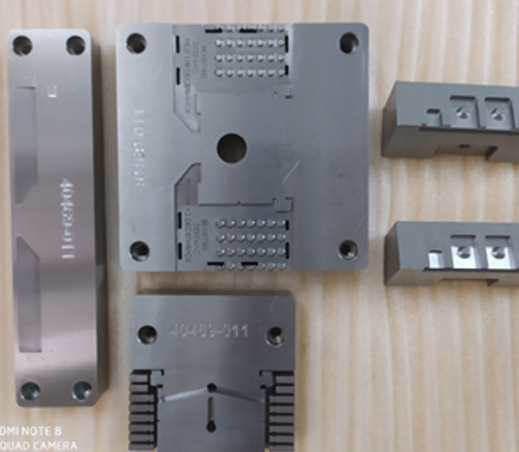

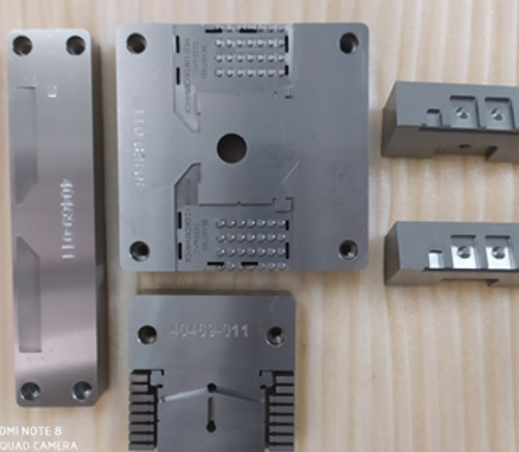

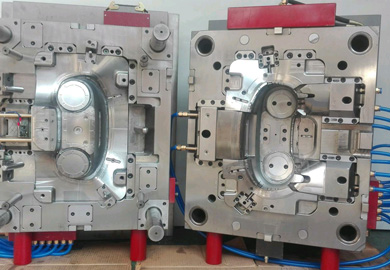

Mould Components/ precision mold componentsare also a part of the mould.GM-TECH not only produces precision moulds but also provides customers with high-precision, low-cost mould parts. For example mould cores, inserts, sliders, lifter, wear plates, ejector pins, etc. Usually, processing accuracy can be controlled within + /-0.015mm. Delivery time is 2-3 weeks, DHL or FedEx will take about 3 days for shipping.

All the steel and tolerances of the parts are processed according to the drawings of the customers. In order to ensure the quality of parts processing, we will provide customers with dimensional measurement report, hardness measurement report, material proof.

We also use new technology to do DLC surface treatment to guarantee the life of the parts.

Mould Component Features

All the steel and tolerances of the parts are processed according to the drawings of the customers. In order to ensure the quality of parts processing, we will provide customers with dimensional measurement report, hardness measurement report, material proof.

We also use new technology to do DLC surface treatment to guarantee the life of the parts.

Plastic injection mold components/ Plastic mold components/ Injection mold componentsare also a part of the mould.GM-TECH not only produces precision moulds but also provides customers with high-precision, low-cost mould parts. For example: mould cores, inserts, sliders, lifter, wear plates, ejector pins, etc. Usually, processing accuracy can be controlled within + /-0.015mm. Delivery time is 2-3 weeks, DHL or FedEx will take about 3 days for shipping.

All the steel and tolerances of the parts are processed according to the drawings of the customers. In order to ensure the quality of parts processing, we will provide customers with dimensional measurement report, hardness measurement report, material proof.

We also use new technology to do DLC surface treatment to guarantee the life of the parts.

We also provide metal insert moldingand plastic parts injection molding.

Send product request

Other supplier products

| Product Development | Our company is not engaged in product development, but we are willing to assist customers to design product appearance and product structure in cas... | |

| Mould Slide | GM-TECH, a plastic injection manufacturer, has been manufacturing tools for injection molding of plastics for various industries for more than 10 y... | |

| Mould Component | Plastic injection mold componentsare also a part of the mould. As one of plastic injection molding companies, GM-TECH not only produces precision m... | |

| Die Casting | We are a plastic injection manufacturer. In the spirit of a "one-stop-shop", our own tool workshop as well as an assembly and an international sale... | |

| CNC Components | CNC Components Gmmoldtech CNC component can greatly reduces the number of tooling, and complex tooling is not needed to process complex parts. ... |

Same products

| Zbk03 Series Roots Vacuum Pump/Roots Pump | Seller: Greentech International (Zhangqiu) Co., Ltd | ZBK series roots vacuum pump is a kind of coarse vacuum acquisition of equipment, it is widely us... | |

| Quick-response Mechanical seal M74N-140 for power generation | Seller: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "Quick-response Mechanical seal M74N-140 for power generation Is YOYIK for the use of turbine uni... | |

| "High-reliability Support ring Y10-4 for power station | Seller: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "High-reliability Support ring Y10-4 for power station Deyang YOYIK have power plant professional... | |

| "Wear Resistance dn50 globe valve WJ25-F1.6P for thermal power plant | Seller: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "Wear Resistance dn50 globe valve WJ25-F1.6P for thermal power plant YOYIK professional productio... | |

| High-efficiency Superheater outlet plug valve SD61H-P61305V SA-182 F92 for power generation | Seller: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "High-efficiency Superheater outlet plug valve SD61H-P61305V SA-182 F92 for power generation Deya... |