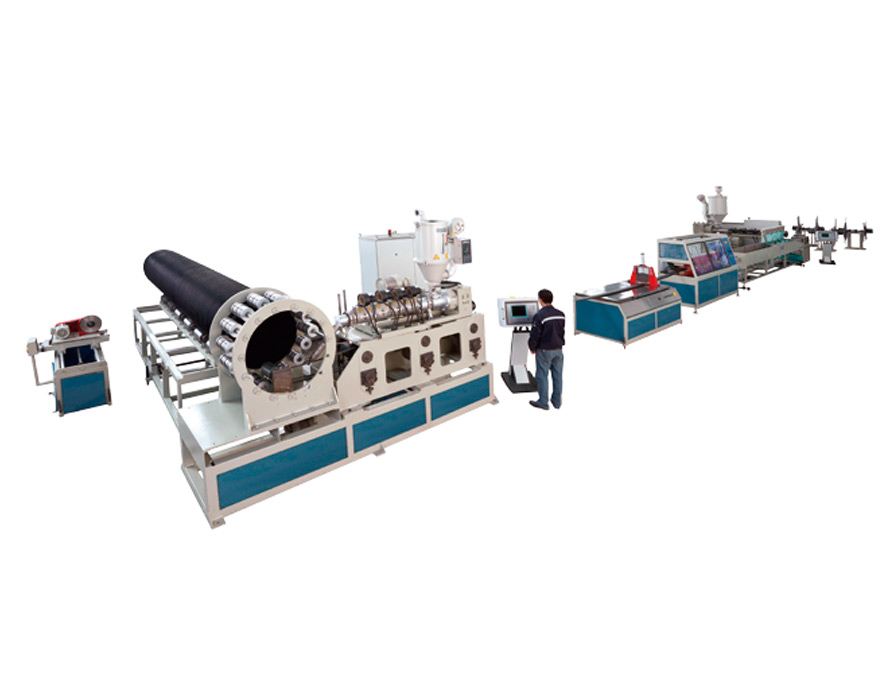

EVA, POE Photovoltaic Film Extrusion Line

With the deterioration of environment and ecology, many countries attach great importance to the development of new energy, among which solar energy is widely used. Our company has independently researched and developed EVA, POE photovoltaic film extrusion line which is used for producing protective film of solar cell modules and we have provided many complete poe film extrusionand eva film extrusion lines for domestic and oversea customer. In order to help our customers successfully produce high quality EVA, POE photovoltaic film, we also send our professional technical engineers or commissioning engineers to customers factories.

Introduction of EVA, POE Photovoltaic Film Extrusion Line

Automatic gravimetric feeding system guarantees variety of solid, liquid additives and raw materials high-precision feeding. Low-temperature extrusion system to ensure adequate mixing in the stable of plasticizing to prevent additives crosslinking. Special design of casting process gives the good solution to roller adhesion. Professional online tempering device to get rid of inner stress. Tension control system ensure the flexible sheets conveying placidly during cooling, pulling and winding process.The on-line thickness measuring and defect inspecting system can provide real-time feedback of the production quality of EVA, POE solar film.

Technical parameter of EVA, POE Photovoltaic Film Extrusion Line

|

Model |

Extruder type |

Products thickness(mm) |

|

|

Single extrusion |

JWS160 |

300-450 |

|

|

Co-extrusion |

JWS160+WS180 |

750-850 |

|

|

Co-extrusion |

JWS180+WS180 |

800-1000 |

|

|

Co-extrusion |

JWS180+WS200 |

900-1100 |

Introduction of PP, PE Solar Photovoltaic Cell Back Sheet Extrusion Line

This production line is used to produce high-performance, innovative fluorine-free solar photovoltaic backsheets that conform to the trend of green manufacturing. Our sheet extrusion line adopts multi-layer co-extrusion technology and special screw structure according to the feature of raw materials. The unique tempering setting design, combined with high-precision thickness gauge, visual inspection system and automatic winding system, fully guarantees the excellent quality of products.

Technical parameter of PP, PE Solar Photovoltaic Cell Back sheet Extrusion Line

|

Model |

Extuder type |

Products thickness(mm) |

|

|

3 extruders co-extrusion |

JWS75+JWS130+JWS75 |

750-850 |

|

|

5 extruders co-extrusion |

JWS65+JWS65+JWS120+JWS65+JWS65 |

800-900 |

Introduction of FPV- Floating Photovoltaic Power Station

Floating photovoltaic project is to install photovoltaic power generation components on the floating body on the water surface, which has many advantages as follows:

It does not occupy land and the water area can be fully utilized.

Floating photovoltaic power stations can reduce water evaporation, improve water quality, and inhibit algae growth.

Due to the cooling effect of water on photovoltaic modules and cables, compared with ground-mounted systems, floating photovoltaic power stations can effectively improve power generation efficiency.

Introduction of JWZ-BM500/1000 Blow Molding Machine:

Our JWZ-BM500/1000 blow molding machine is suitable for producing different kinds of floating products and adopts high output extrusion or double-layer co-extrusion with accumulating die head and hydraulic servo control system.

Technical parameter of JWZ-BM500/1000 Blow Molding Machine

|

ModeI |

Unit |

BM500 |

BM1000 |

|

Die head structure |

Accumulating type |

||

|

Main screw diameter |

mm |

120 |

135 |

|

Max plasticizing capacity (PE) |

kg/h |

350-450 |

550-650 |

|

Driving motor |

kW |

132 |

160 |

|

Accumulating volume |

L |

26 |

45 |

|

Oil pump motor power |

kW |

30 |

45 |

|

Clamping force |

KN |

800 |

1800 |

|

Max space between platen |

mm |

500-1400 |

700-1900 |

|

Platen size W*H |

mm |

1020-2400 |

1600*2400 |

|

mm |

800-2500 |

1500*2500 |

|

|

Heating power of die head |

kW |

25 |

38 |

|

Machine dimension L*W*H |

m |

||

|

Machine weight |

T |

45 |

63 |

|

Total power |

kW |

240 |

302 |

The Application of EVA, POE Photovoltaic Film Extrusion Line

EVA film is a thin film product which is made of EVA as the main raw material, added with various modifying additives, fully mixed, heated by the production and processing equipment, cast and extruded. The cured EVA can withstand atmospheric changes and has elasticity. After bonding with the glass, it can improve the transmittance of the glass, play a role in enhancing the transmittance and gain the output of the solar cell module. Therefore, it is an ideal packaging material for solar cell modules and glass.

As a professional extrusion line supplier, we can offer kinds of plastic profile production linefor sale, anything you need, please leave us a message.

Send product request

Other supplier products

| PP PS Environmental Sheet Extrusion Line | PP PS Sheet Extrusion Line We’re professional plastic sheet extrusion machine manufacturer with over 25 years’ technical R&D exp... | |

| PVC Foam Board Extrusion Line | PVC Foam Board Extrusion Line We have researched and developed on PVC skinning foam board extrusion machine for over 25 years, and have exported t... | |

| Extruder Screw & Barrel | All screws and barrels of our extrusion lines are produced by our own professional extruder screw barrel factory, called Zhoushan Jwell Screw&b... | |

| High Pressure RTP Twisted Composite Pipe Extrusion Line | RTP (Reinforced Thermoplastic Pipe) is a new type of pipe that combines the unique advantages of thermoplastic(PE80, PE100, PA, PER, PVDF, etc), su... | |

| TPO PVC EVA HDPE Waterproof Geomembrane Sheet Extrusion Line | With over 25 years experience and have ranked No.1 in the plastic extrusion industry for 11 consecutive years, accumulating rich manufacturing expe... |

Same products

| High Vacuum Pump 2be 203 Series Water Ring Pump | Seller: Greentech International (Zhangqiu) Co., Ltd | Application scope and characteristics: Greentech International (Zhangqiu) Co., Ltd is the profes... | |

| Advanced technology Electric regulating valve T967H-64 for thermal power plant | Seller: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "Advanced technology Electric regulating valve T967H-64 for thermal power plant The use of advanc... | |

| High Security Superheater outlet plug valve SD61H-P54.5150V for power plant | Seller: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "High Security Superheater outlet plug valve SD61H-P54.5150V for power plant Deyang YOYIK is a st... | |

| "Low Failure Rate Bellows valves WJ10F-1.6 for power plant | Seller: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "Low Failure Rate Bellows valves WJ10F-1.6 for power plant Deyang Dongfang Yoyik is a trade produ... | |

| Customized Check valve H42H-16C for power station | Seller: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "Customized Check valve H42H-16C for power station Our company is equipped with high-precision cu... |