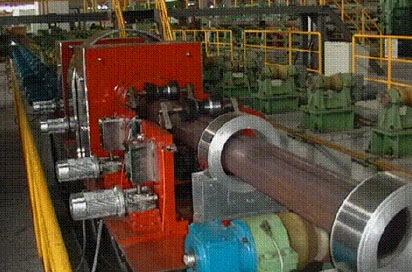

Drill Pipe Magnetic Flux Leakage Detector MFL-308

Specifications: diameter Φ73 / Φ89 mm, length 9.6m or so

Detection speed: 6-20 m / min

Acceptance criteria: American Petroleum Institute API testing standards

The main detection principle of the MFI magnetic flux leakage pipeline inspection method is that the workpiece is magnetized (close to saturation) to have a certain magnetic flux density to generate a leakage magnetic field at the discontinuity, and the magnetic field sensor sends the output signal to the operational amplifier.

Due to the magnetic saturation state, the workpiece has a relatively high magnetic field strength and magnetic field density, and the magnetic lines of force are not limited so that the surface of the workpiece has a large magnetic leakage, which is favorable for on-site detection.

The magnetic sensitive sensor scans along the surface of the magnetized ferromagnetic material, pick up the defect leakage magnetic field and forms a defect electrical signal to achieve the purpose of finding the defect position and parameters.

Non-destructive mfl pipeline inspectiontechnology is widely used in the detection of metal materials and the evaluation of related products due to its fast detection speed, high reliability and low surface cleanliness. Different from magnetic particle detection and detection, the signal in magnetic flux leakage detection is not displayed by magnetic powder, and it has no pollution to the environment: due to various sensitive components (such as Hall element and coil method), the detection result is directly output by electric signal, which is easy to connect with computer to realize digital Processing, so the detection results can be stored and reproduced, facilitating the analysis of the detection signal and the trend analysis of the detection results.

Drill Pipe Magnetic Flux Leakage Detector MFL-308 Performance

|

Drill pipe inspection method |

Drill pipe straight ahead, test assembly fixed |

|

Detection range |

F60-F168drill pipe |

|

transport system speed |

6-20m/min;variable frequency range |

|

Testing methods |

Automatic charging, Automatic testing, Automatic sorting |

|

The sensitivity of hole detection |

|

|

Accuracy of section area measurement |

2-4% |

|

Position resolution accuracy |

20mm |

|

Non-detection zone |

£100mm(drill pipe body) |

|

False alarm rate |

£0.5% |

|

Remaining magnetism after demagnetization |

£10GS |

|

The internal and external surface coverage |

100% |

|

Equipment usage environment |

Working temperature:40°-minus50°; Working humidity:0-95%; |

Nanjing BOKENA Automation System Co., Ltd., originated from the eddy current testing laboratory of the Nanjing University of Technology. It isone of the most professional ndt testing equipment suppliersin China. We sincerely invite and welcome people from all around the world to invest and create more values together.

Send product request

Other supplier products

| BKNET-101 Automatic Eddy Current Testing | The eddy current testing (BKNET-101) is a fully automated eddy current inspection systemthat uses large-scale imported integrated circuits combined... | |

| MFL101 Tank Floor MFL Scanner | Technical Characteristics of MFL101 MFL Tank Floor Scanner Unique full modular structure, from the main body of the computer mechanism the handle ... | |

| Bearing Ring Crack and Hardness Combination Flaw Detector TQJC-02 | During the processing of bearing rings, various defects are often generated on the surface or inside, and cracks occupy a large proportion of all d... | |

| Bolt Eddy Current Sorter BKNFX-11 | Bolt: Mechanical parts, cylindrical threaded fasteners with nuts. A type of fastener consisting of a head and a screw (a cylinder with an external ... | |

| Eddy Current Testing for Auto Parts | NDTApplication in Automotive Industry: Eddy current hardness testingtechnology has been widely used in the detection of metal components in the ... |

Same products

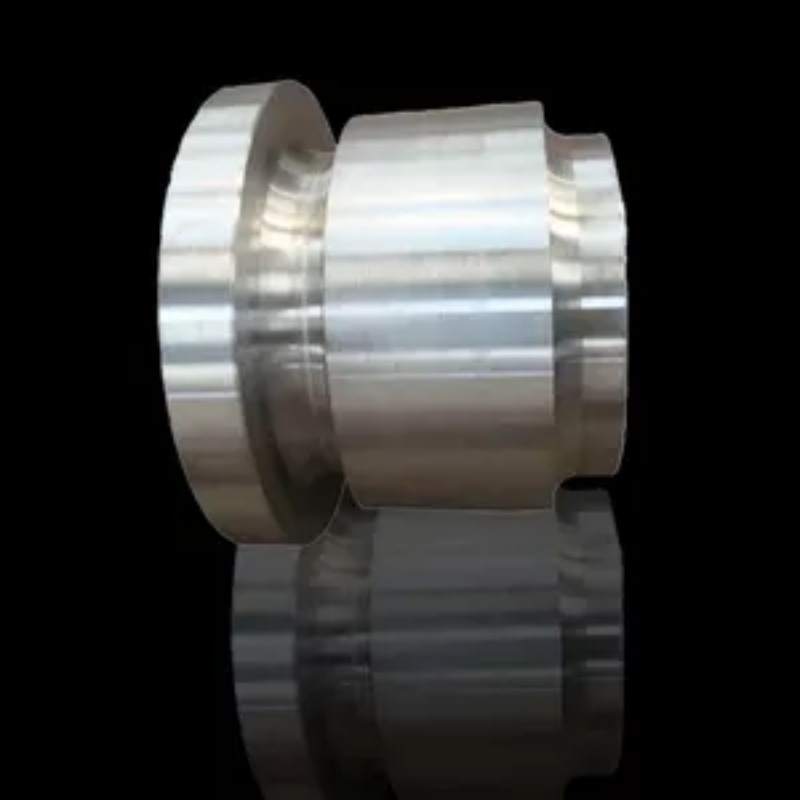

| Drum Forging | Seller: Shandong Runchi Machinery Technology Co., Ltd | Drum Forging Drum Forging Brand origin: Runchi shandong Processing ability: turning, milling, pla... | |

| Wheel Hub Forging | Seller: Shandong Runchi Machinery Technology Co., Ltd | Wheel Hub Forging Wheel Hub Forging Main features: [Manufacturing Standards] Strictly produce for... | |

| Nozzle Forging Nozzle | Seller: Shandong Runchi Machinery Technology Co., Ltd | Nozzle Forging Nozzle Forging Brand origin: Runchi shandong Processing ability: turning, milling,... | |

| Marine Forging | Seller: Shandong Runchi Machinery Technology Co., Ltd | Marine Forging Marine ForgingMain features: [Manufacturing Standards] Strictly produce custom f... | |

| Bearing Housing | Seller: Shandong Runchi Machinery Technology Co., Ltd | Bearing Housing Product Name: Bearing housingBrand origin: Runchi shandong Processing ability: ... |