Portable Magnetic Flux Leakage Testing Equipment

Magnetic flux leakage test refers to the formation of a leakage magnetic field on the surface of a test piece after it is magnetized due to defects on the surface or near-surface of the test piece. People can detect defects by detecting changes in the leakage magnetic field.

Briefly describe the magnetization of ferromagnetic components. In the magnetic non-destructive testing, magnetization is the first step to realize the detection, which determines whether the leakage magnetic field signal can be generated, and also affects the performance characteristics of the detection signal and the structural characteristics of the detection device. Like magnetic particle inspection, magnetization is achieved by a magnetizer, including both a magnetic source and a magnetic circuit. The magnetic source and the magnetic circuit change depending on the structure of the member to be tested.

What kind of magnetization can be divided into several categories? The magnetization methods can be generally divided into five categories, namely, alternating current magnetization mode, direct current magnetization mode, permanent magnet magnetization mode, composite magnetization mode, and integrated magnetization method.

What are the characteristics of magnetic flux leakage detection technology?

Because leakage magnetic field detection uses magnetic sensors to detect defects, compared with magnetic powder, penetration and other methods, the magnetic flux leakage equipmenthas the following advantages:

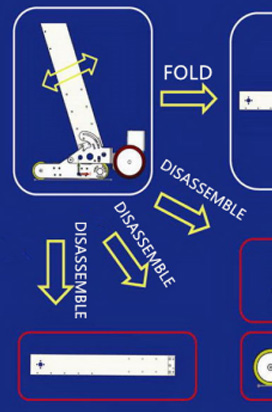

BKN's portable magnetic flux leakage testing equipmentare capable of detecting workpieces efficiently and accurately.

Nanjing BOKENA Automation System Co., Ltd., originated from the eddy current testing laboratory of the Nanjing University of Technology. It isone of the most professional ndt testing equipment suppliersin China. We sincerely invite and welcome people from all around the world to invest and create more values together.

Send product request

Other supplier products

| MFL101 Tank Floor MFL Scanner | Technical Characteristics of MFL101 mfl tank floor inspection The mfl tank floor scannerhas a unique full modular structure, from the main body of... | |

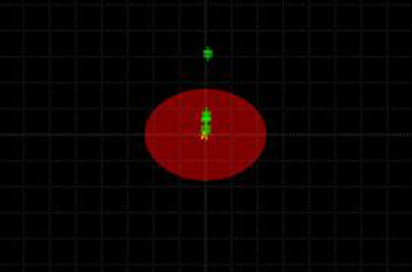

| GTET-02 Cylinder Liner Eddy Current Testing Machine | GTET-02 Cylinder Liner Eddy Current Machine Introduction The rate of missed standard defect is 0%; the rate of false positives (only misidentifi... | |

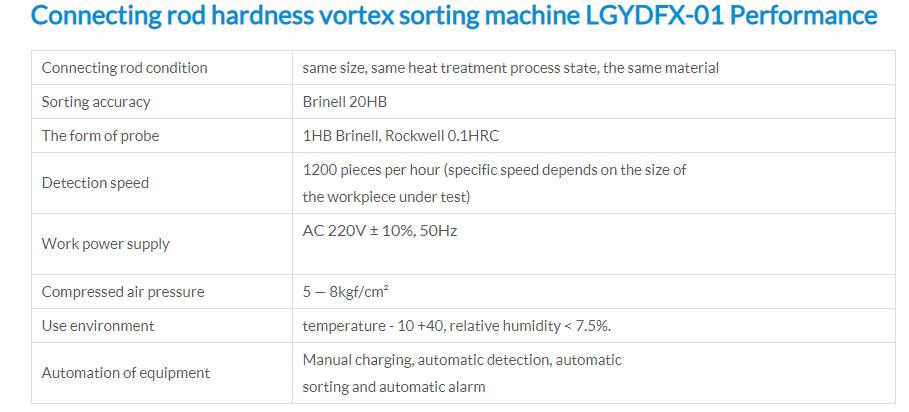

| Connecting rod hardness vortex sorting machine LGYDFX-01 | The connecting rod hardness eddy current testing machine has a calibration device, input compensation parameters, automatic/manual temperature comp... | |

| Bolt Eddy Current Sorter BKNFX-11 | Bolt: Mechanical parts, cylindrical threaded fasteners with nuts. A type of fastener consisting of a head and a screw (a cylinder with an external... | |

| MFL101 Tank Floor MFL Scanner | Technical Characteristics ofMFL101 Tank Floor MFL Scanner Unique full modular structure, from the main body of the computer mechanism the handle o... |

Same products

| Drum Forging | Seller: Shandong Runchi Machinery Technology Co., Ltd | Drum Forging Drum Forging Brand origin: Runchi shandong Processing ability: turning, milling, pla... | |

| Wheel Hub Forging | Seller: Shandong Runchi Machinery Technology Co., Ltd | Wheel Hub Forging Wheel Hub Forging Main features: [Manufacturing Standards] Strictly produce for... | |

| Nozzle Forging Nozzle | Seller: Shandong Runchi Machinery Technology Co., Ltd | Nozzle Forging Nozzle Forging Brand origin: Runchi shandong Processing ability: turning, milling,... | |

| Marine Forging | Seller: Shandong Runchi Machinery Technology Co., Ltd | Marine Forging Marine ForgingMain features: [Manufacturing Standards] Strictly produce custom f... | |

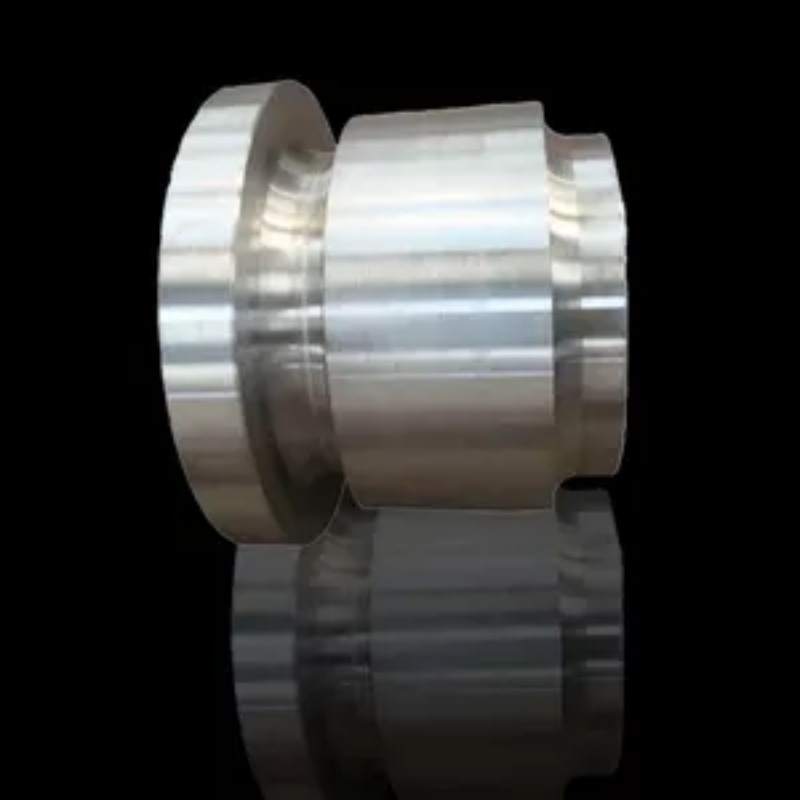

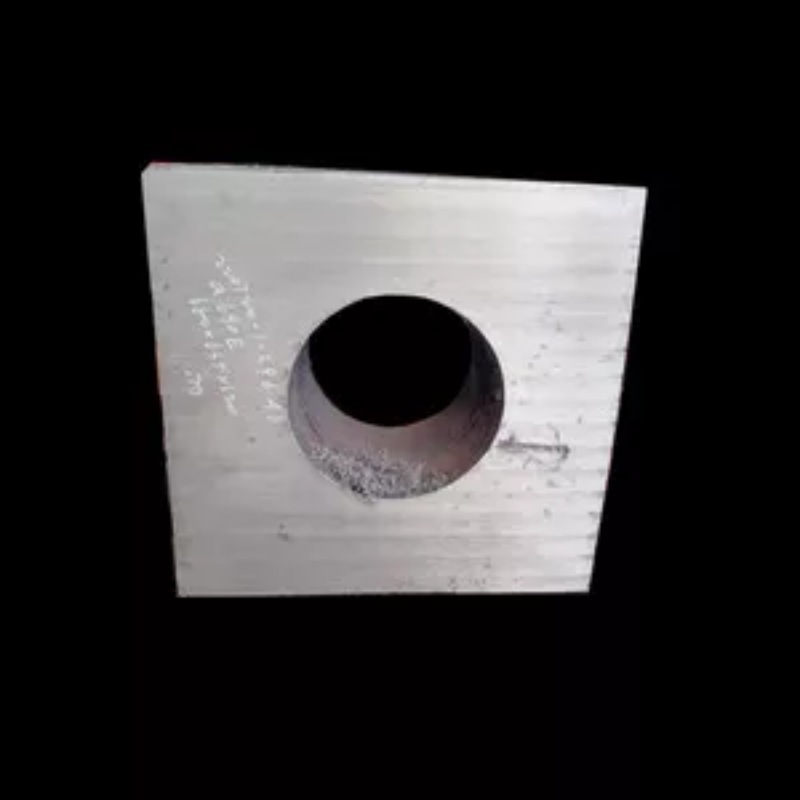

| Bearing Housing | Seller: Shandong Runchi Machinery Technology Co., Ltd | Bearing Housing Product Name: Bearing housingBrand origin: Runchi shandong Processing ability: ... |