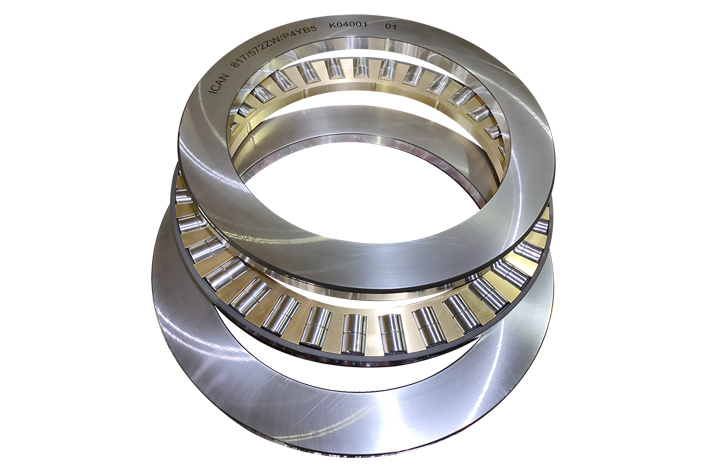

Dry Ball Mill

Dry ball millis suitable for all kinds of metal and nonmetal ores, including materials that will react with water, such as cement, marble, and other building stones, or products that require storage and sales in the form of powder. In addition,among all ball grinding machine, if the concentrator is located in an arid area and water resources are scarce, dry grinding ball millcan be used for water saving.

Advantages of Dry Grinding Ball Mill

Dry ball millneed less water, which greatly saves water consumption compared with wet ball mill.

The material produced by dry ball mill is the finished product.

The efficiency of dry ball mill is higher.

Available for cement ball mill.

Advantages of Dry Grinding Ball Mill

Working Principle of Dry Ball Mill

The dry grinding ball mill is a horizontal cylindrical rotating device, which is driven by outer gear. It is divided into lattice type dry ball mill and multi-bin type dry ball mill. The material enters into the front bin of the mill through the feeding device, and the hollow shaft screw evenly enters into the front bin of the mill. There are stepped lining plates or corrugated lining plates in the bin, which are filled with steel balls of different specifications. The rotation of the cylinder generates centrifugal force to bring the steel balls to a certain height and then fall down, which has a heavy impact and grinding effect on the material. After rough grinding in the front bin, the materials enter the second bin through a single-layer partition board. The bin is inlaid with a flat lining board and steel balls to further grind the materials. The powder is discharged through the discharging grate plate to complete the industrial grinding mill operation.

Main Structure of Dry Ball Mill

Feeding screw for feeding raw material.

The shell is equipped with a manhole for maintenance and replacement of the inner liner.

Discharge part for ball mill to discharge qualified products.

Main bearing.

Transmission part.

Send product request

Other supplier products

| Industrial Centrifuge Machine | Centrifugal concentrator is a kind of equipment for gravity separation of ore particles in a centrifugal force field, which is one of the high-effi... | |

| Horizontal Centrifuge | TWZ series horizontal vibratory centrifuge belongs to the centrifugal dewatering machine, the series of horizontal vibratory centrifuge is mainly u... | |

| Vertical Centrifuge | The vertical centrifuge machineis made up of the screen which diameter range from 700 to 1,000 mm , the rotor body (including the blade), transmiss... | |

| Metallurgical Furnace | CIC main advantage in nonferrous metallurgical furnacelies in the manufacture of horizontal rotary furnace, Rotary refining furnace and bottom blow... | |

| Cement Rotary Kiln | Since 1950s, CIC rotary kiln manufacturerhad started manufacturing of pyro processing equipment. These series of pyro processing rotating kiln equi... |

Same products

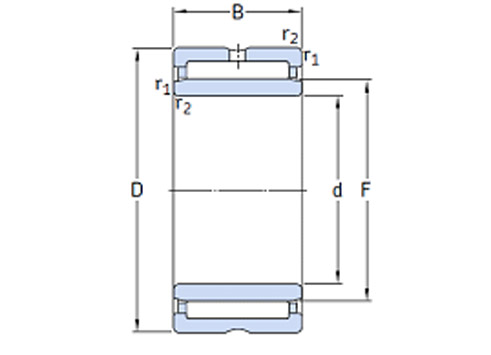

| Cylindrical Roller Bearings | Seller: DLAIAN GUANGYANG BEARING CO., LTD | Cylindrical Roller Bearings Cylindrical roller bearings ( also called CRB in short) are a kind o... | |

| Mono-Pole Magnets | Seller: NingBo BeiLun Meank Magnetics Co.,ltd. | Product Category: mono pole magnets / single pole magnets Product Features: strong magnets, fl... | |

| NKI 25/20 TN Machined Needle Roller Bearing | Seller: THB BEARINGS CO., LTD | Specifications of NKI 2520 TNMachined Needle Roller Bearing Designations NKI25/20TN... | |

| Dry Ball Mill | Seller: CITIC IC LUOYANG HEAVY MACHINERY CO., LTD | Dry ball millis suitable for all kinds of metal and nonmetal ores, including materials that will ... | |

| Silicon Nitride Bearing | Seller: Advanced Material Technologies Corporation | Deep Groove Ball BearingThin Section Ball Bearing |