Core And Cavity Mold Parts

Core And CavityMold Parts

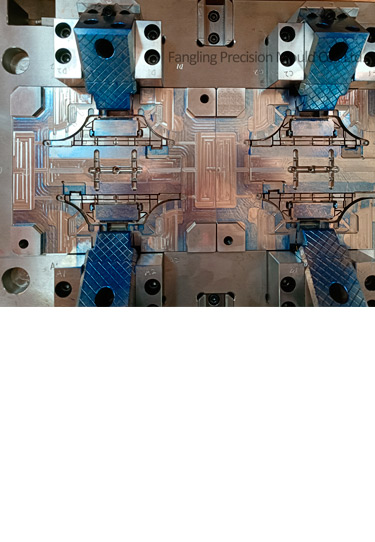

Core and cavity designare used in the injection molding process, where the concave part of the mold is the cavity and the convex part is the core. The core and cavity in mould are used in pairs, with the cavity also referred to as the female mold and the core as the male mold.

DESCRIPTION OF CORE AND CAVITY

What Does Core Mean In Casting?

A core is a preformed, bonded, sand insert placed into the mold to shape the interior of a casting or a part of the casting that cannot be shaped by the pattern. Cores are frequently used to create hollow sections or cavities in a casting.

Function Of Core and Cavity in Injection Molding

The core & cavity are the shaped sections in either half of the mould tool which give the plastic product its final shape. The hot molten material is injected into the core & cavity and then sets hard into shape. The design of this type of mold spare parts is essential in the correct formation of the product.

DETAILS OF CORE AND CAVITY

What Are The Types Of Core?

Generally, cores are of two types:

Green Sand Core: ADVERTISEMENTS: A core formed by the pattern itself, in the same sand used for the mould is known as green sand core. The pattern is so designed that it provides the core of green sand. The hallow part in the pattern produces the green sand core.

Dry Sand Core: A core is prepared separately in core boxes and dried, is known as dry sand core. The dry sand cores are also known as process cores.

If you want to know more precision mold services, please visit our website.

Now the price of precision mold partsis reasonable, anything you need, please contact us.

Send product request

Other supplier products

| PRECISION MOLDS | Our plastic injection moulding process produces custom - rapid prototypes and end-use production parts in 15 days or less. We use aluminium moulds ... | |

| PRECISION PLASTIC INJECTION MOLDING | PRECISION PLASTIC INJECTIONMOLDING Digital manufacturing for plastic prototypes and on-de-mand production parts. Request an injection molding quot... | |

| Trial-Run Molding | A mould trialis a process by which a new mould is optimised in order to produce the desired products as efficiently as possible. This makes it one ... | |

| Stamping Mold Parts | Stamping — also called pressing — involves placing flat sheet metal, in either coil or blank form, into a stamping press. In the press,... | |

| Cylindrical Mold Parts | Cylindrical Mold Parts Customized cylindrical partsaccording to customer's drawing requirement. Jobs: Hard Turning, Centerless Grinding, Punch ... |

Same products

| Galvanized Fishtail Terminal End for Highway Guardrail | Seller: Wuhan Dachu Traffic Facilities Co., Ltd | Galvanized Road Fence Highway Guardrail Crash Barrier Terminal Endare the specially designed end ... | |

| COMMUNICATIONS PARTS | Seller: ShenZhen Haohaichang Industrial Co.,Ltd | High Precision Parts are radar system componentsin radar systems, where accuracy, reliability, an... | |

| POM CNC TURNING PARTS | Seller: ShenZhen Haohaichang Industrial Co.,Ltd | CNC POMturning parts are precision components made from polyoxymethylene (POM) using computer num... | |

| Nut | Seller: ShenZhen Haohaichang Industrial Co.,Ltd | Nuts are essential hardware components that work in tandem with bolts, screws, or other threaded ... | |

| HEATINGS/APPLIANCES PARTS | Seller: ShenZhen Haohaichang Industrial Co.,Ltd | High Precision Parts are essential components in heating and appliance systems, contributing to t... |