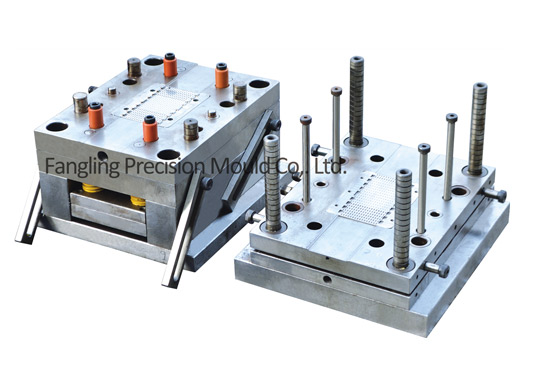

Mold Assembly

When designing plastic injection moulded parts to be used in conjunction with other parts, the assembly must be considered. There are several assembly techniques, mechanical fastening, press fit, hot staking, snap fit, welding, solvent bonding and adhesive bonding. We’ll cover each of these in more detail over the next two articles and how they fit into the design process.

When designing for plastic injection moulding, the aim is to reduce the overall number of parts for any given product. There are several advantages to this aim, not only will it reduce costs but it will make assembly easier. When designing, designers should lookout for any opportunities to simply the assembly process through a more efficient design.

DETAIL OF plastic mold assembly

Six Points Of Preparation For Mold Assembly

Familiarity with assembly procedure

A thorough understanding of assembly drawings

Checking Parts

Mould Acceptance Technology

Developing Assembly Sites

Preparing mold standard parts and related materials

DESCRIPTION OF injection molding assembly

How to Design for Assembly

Searching for Symmetry

It might be hard to wrap your mind around at first, but many assemblies traditionally constructed of two unique components can often be made from a pair of identical parts.

Self-Mating Parts

But why not get rid of the screws altogether? Our gear housing example is now symmetrical, but it still requires manual installation of threaded inserts, never mind keeping track of all those pesky screws and washers.

Family Molds

Another way to achieve hero status is the use of family molds, which are ideal when producing a series of parts with similar shapes and sizes.

Hardware Harmony

Everyone’s heard the adage about reinventing the wheel. Designing and manufacturing your own nuts, screws, shafts, pins, keys, and dozens of other off-the-shelf components should be avoided at all costs. Better to redesign your product around standard hardware items, especially if production volumes are expected to rise at some point.

Moving to Monoform

The properties that make plastics such as polypropylene (PP) and styrene butadiene (SB) excellent candidates for living hinges.es of the chosen plastic are appropriate for the environment in which they’ll be used.

Easy Assembly

If a product must be assembled, attempt to make the task easier by orienting the various screws and connectors in such a way that all are accessible from the same side, thus minimizing part flipping and rotating.

If you need any kinds of precision mold services, please contact us, as a professional custom plastic molding company, Fangling is willing to offer you high quality products.

Send product request

Other supplier products

| EDM Sinking Mold Parts | Sinker EDMParts Die sinking EDM spare partsconsist of an electrode and the workpiece is submerged in an insulating liquid. The electrode and the w... | |

| Trial-Run Molding | A mould trialis a process by which a new mould is optimised in order to produce the desired products as efficiently as possible. This makes it one ... | |

| Standard Mold Parts | We provide DIN(Deutsche Industrie Normen) standard mould partsof high quality to our customers. The mold standard partsare applied to all kinds of ... | |

| PRECISION MOLD PARTS/SPARE PARTS | This shape of a mold is predetermined by a mould, a block that has been hollowed out. Aluminum, steel, alloys, and copper are the most common mater... | |

| PRECISION PLASTIC INJECTION MOLDS/TOOLS | When it comes to custom injection molding, precise moulds and precision equipment are required for precision molding or PIM. Among the topics cover... |

Same products

| Galvanized Fishtail Terminal End for Highway Guardrail | Seller: Wuhan Dachu Traffic Facilities Co., Ltd | Galvanized Road Fence Highway Guardrail Crash Barrier Terminal Endare the specially designed end ... | |

| COMMUNICATIONS PARTS | Seller: ShenZhen Haohaichang Industrial Co.,Ltd | High Precision Parts are radar system componentsin radar systems, where accuracy, reliability, an... | |

| POM CNC TURNING PARTS | Seller: ShenZhen Haohaichang Industrial Co.,Ltd | CNC POMturning parts are precision components made from polyoxymethylene (POM) using computer num... | |

| Nut | Seller: ShenZhen Haohaichang Industrial Co.,Ltd | Nuts are essential hardware components that work in tandem with bolts, screws, or other threaded ... | |

| HEATINGS/APPLIANCES PARTS | Seller: ShenZhen Haohaichang Industrial Co.,Ltd | High Precision Parts are essential components in heating and appliance systems, contributing to t... |