200L Drum Equipment Production Line

The steel drum is manually placed onto the transmission rack after seam welding, and inserted into forming plate through hydraulic driver. Extrusion forming is directly realized by forming plate moving back and forth. Featured by high flanging precision and efficiency, it is applicable to cold-rolled sheets and is hydraulically driven. Its program can be written and changed as needed for accurate movement and simple operation.

Other supplier products

|

|

200L Drum Equipment Production Line |

The steel drum is manually placed onto the transmission rack after seam welding, and inserted into forming plate through hydraulic driver. Extrusio... |

|

|

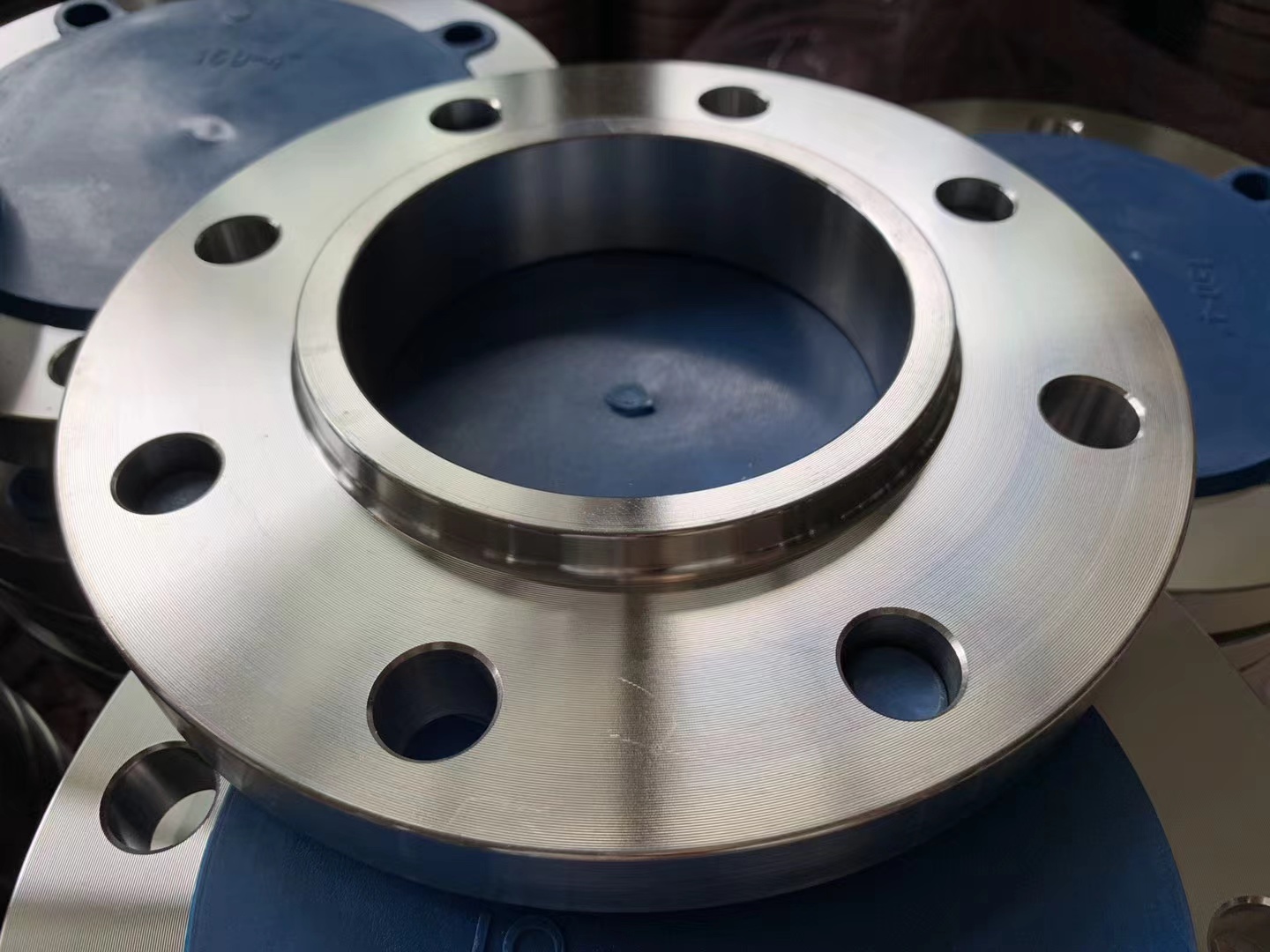

Single-head Double-head Flanger for Fuel Tank |

Main purpose of flanger for fuel tank: trimming, shearing,crimping, flanging,hemming,rabbeting, marking,ribbing groove,spinning, etc.of round metal... |

|

|

Coiled Plate Leveling Machine |

Applicable to leveling of various coiled plates, material thickness: 0.6-3.0mm

Shandong Taisen Packing Mechanical Equipment Incorporated Company is... |

|

|

High Quality Automatic Muffler Hole-punching Machine |

Material thickness: 0.5-1.2mm, diameter ø80-ø120mm, height: 200-800mm, applicable materials: common carbon steel sheets and stainless... |

|

|

High Performance Automatic Leak Testing Machine for Drum |

Leak testing machine for drum, also known as leak tester or leak checking machine, is mainly used for automobile, internal combustion engine, motor... |

All supplier products

Same products