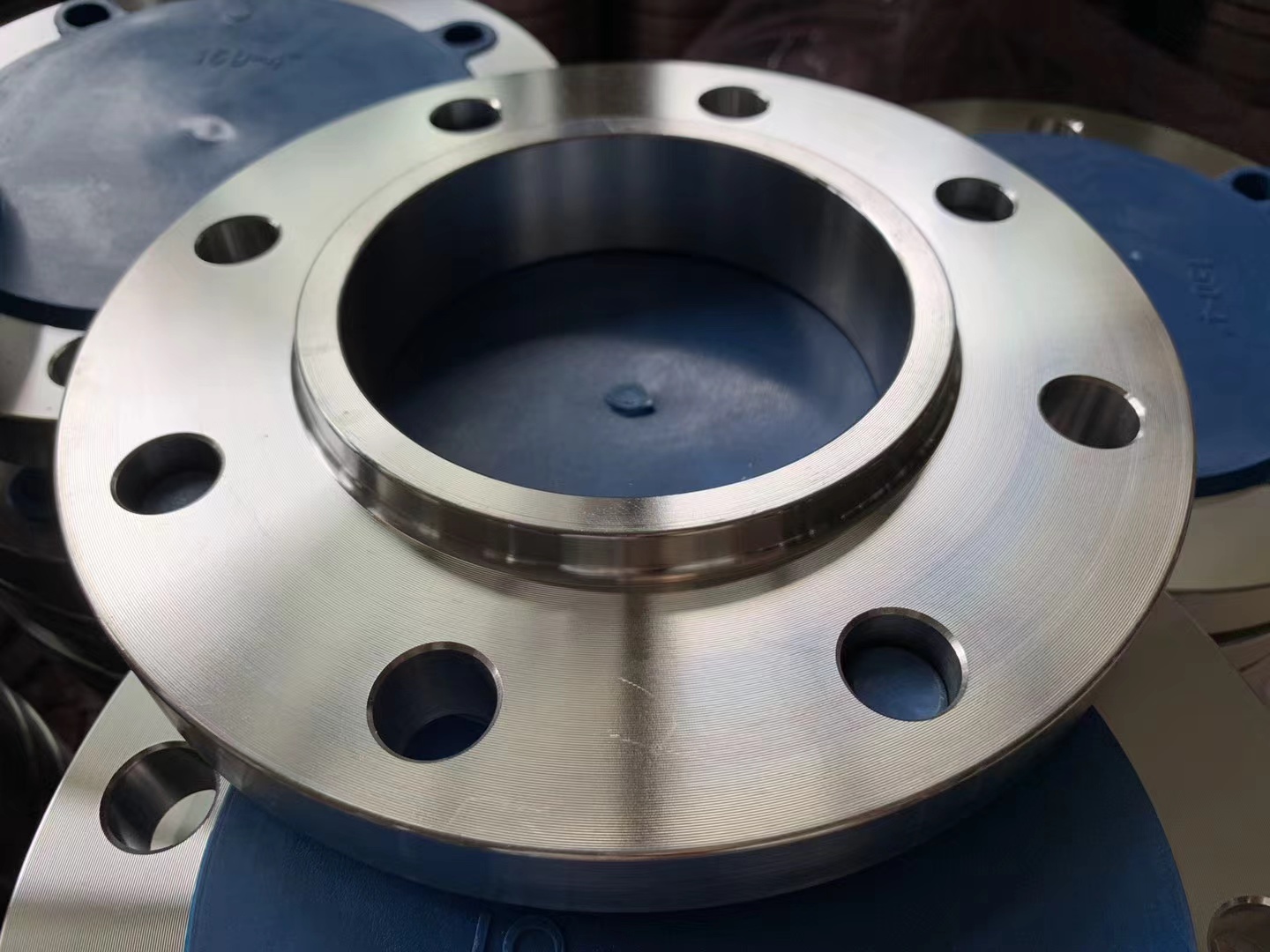

Wear-resistant 200L Chemical Drum Double-end Sealing Equipment

Chemical drum equipment is used to produce drums used in chemical industry. So what are the details ought to be noticed in the usage of chemical drum equipment? Let's have a look: 1.the guide of the opening and closing mold adopted to the double linar guide, which gain the advantages of small resistance, high speed and guide precision, and wear resistance.2.Hard chrome is plated on the polish rod bring the long life of wear resistance. 3.Hydraulic direct clamping structure is used to make sure no phenomenon of swell mold and fine traceless of die line.4.traditional cooper sleeve on the opening mold is replaced by self-lubricating bearing to avoid the lubricating oil pollution of chemical barrels.

Other supplier products

|

|

200L Drum Equipment Production Line |

The steel drum is manually placed onto the transmission rack after seam welding, and inserted into forming plate through hydraulic driver. Extrusio... |

|

|

Tyson Mechanical Semi-automatic Spot Welder |

Novel structure, unique design and good rigidity. With high-precision guide mechanism, it is characterized by good wearability,pressurization of st... |

|

|

Two-roller Automatic Feeding Furling Round Machine |

Two-roller rolling furling round machine is featured by small volume, light weight, low noise, steady and reliable operation, etc. It mainly consis... |

|

|

Automatic Horizontal A Molding Flanging Machine Suppliers |

Equipment size: 2250x750x2000mm fuel tank size: 880x680x1100mm forming flanging machine: automatic forming flanging, a complete, easy to use, a key... |

|

|

High Quality Automatic Barrel Double-end Sealing Machine |

The drum after flanging, expansion and corrugation is placed onto transmission rack of sealing machine, and drum cover and bottom are manually plac... |

All supplier products

Same products