Horizontal Axle Press

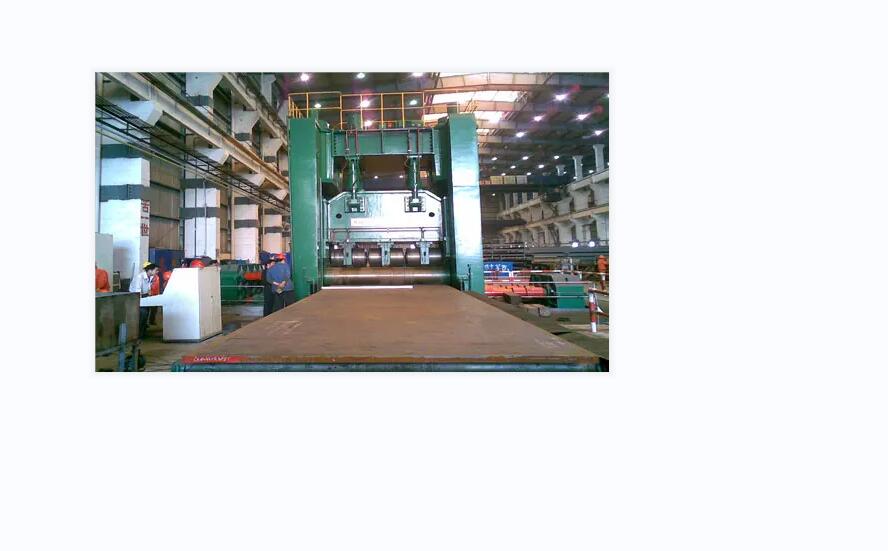

The horizontal press machine is the installation equipment for the rolling bearing of the railway vehicle system. Its main purpose is to press the rolling bearing to the wheel journal by cold pressing. The horizontal hydraulic press machine is composed of a body, a hydraulic station, and a console. The hydraulic station and the console should be arranged close to the host. The rigid rails on the site and the guide rails on the body should be connected evenly.

EZHONG specializes in the production of horizontal wheel and axle press equipment. As a professional wheel press machine manufacturer, EZHONG Hubei Heavy Equipment Co. Ltd has almost 70 years of production experience and technology of wheel press machine. On the basis of absorbing foreign advanced technology, we have developed horizontal hydraulic press machine with our own characteristics. The horizontal hydraulic press for sale is simple and convenient to operate, has high processing accuracy, and will not crush the bearings.

Horizontal Hydraulic Press Machine Specification

EZHONG Wheel Press Machine Details

Wheel press machine tool composition: Machine front fixed beam, movable beam, after the support, chassis, hydraulic system, car device, electrical system is composed of the main parts.

Safety protection of horizontal press machine:

1. When the system overvoltage, with pressure relay shutdown protection and overflow protection.

2. Install an emergency stop button at each of the fixed beam and console locations.

3. The safety system of mechanical and electrical equipment and control conforms to the national standards of China or corresponding standards, and the safety interlock system is reliable.

4. The oil is cooled by air. When the oil temperature reaches 60 °C, the horizontal hydraulic press machine will automatically alarm and stop.

Horizontal Press Machine Optional Features

1. The horizontal hydraulic press for sale has independent power mechanism and electrical system.

2. The horizontal press machine adopts button centralized control.

3. Process action is controlled by PLC.

4. The wheel press machine can realize two operation modes of inching and semi-automatic.

Notes Of EZHONG Horizontal Hydraulic Press Machine Operation Process

1. Check whether the horizontal hydraulic press brake is placed horizontally and the power supply is safe.

2. Check whether the hydraulic oil is in place and the circuit is not damaged.

3. Start the motor and check whether the rotation direction of the motor is correct.

4. Jog the hydraulic system to check that there is no leakage or abnormal sound in the hydraulic system.

5. Run the horizontal hydraulic press system with an empty vehicle to drain the air in the system.

6. Adjust the workbench according to the motor stator, press-fit and debug, so that the horizontal hydraulic press machine meets the press-fit requirements.

7. After the normal press-fitting work, pay attention to the maintenance of the horizontal bending press machine.

8. This bending press machine produced by our company requires a relatively high press-fitting accuracy, and the equipment is equipped with a pressure and stroke tester.

You can see the progress of the press on the screen, which is very accurate. In addition to the equipment's own program control, the requirements of the operator must be serious. To improve

For the service life of the wheel press machine, we must strictly operate the wheel press machine correctly.

The Advantages Of Horizontal Press Machine

The operation of our horizontal press brake for sale is simple and convenient, high efficiency, time-saving, labor-saving, and cost-saving.

The high precision of press-fitting concentricity ensures a high qualified rate of products produced.

The stroke of the horizontal hydraulic press machine can be adjusted according to the large size of the press-fitting parts, no matter how big the product is, it can be press-fitted.

As a professional wheel press machine manufacturer, our equipment pressure can be adjusted at any time, and the user can adjust the pressure system of the horizontal hydraulic press machine according to the approximate pressure required by the press.

The professional hoisting structure is made to facilitate the movement of the wheel press machine at any time.

All kinds of fixtures are equipped at the factory, which is convenient for users to press-fit all kinds of axles and bearings.

The horizontal press brake for sale is at a good plate bending machine price.

The whole machine adopts integral steel plate welding, which is thick and beautiful, and has good stability.

What is Hydraulic Press Machine Used for?

This wheel press machine from EZHONG wheel press machine manufacturer is suitable for metallurgy, mine machine repair, machine manufacturing and large motor manufacturing, mainly used for large shaft parts of the pressure assembly and disassembly work.

We can also offer kinds of roll forming machine second hand for sale, if you have needs, please contact us.

Other supplier products

|

|

Press Machine For Sale |

EZHONG is a professional hydraulic press machinemanufacturer. At present, China's largest horizontal axle press machine is manufactured by EZHONG. ... |

|

|

W43T Leveling Machine |

EZHONG specializes in the production of heavy plate levelers, composite plate levelers, high-strength engineering machinery levelers, high-strength... |

|

|

Plate Leveling Machine For Sale |

EZHONG specializes in the production of heavy plate leveling machines, composite plate levelers, high-strength engineering machinery levelers, high... |

|

|

3-х валковый листогибочный станок |

трехвалковый гибочный станокс ЧПУ имеет конструкцию нижнего цилиндра. Верхний рабочий валок этой трехвалковой гибочной машины является основным вед... |

|

|

3 Rolls Plate Bending Machine |

The CNC 3/three roll bending machine adopts the structure of the lower cylinder. The upper working roller of this 3 roll bendingmachine is the main... |

All supplier products

Same products

|

|

FITR Moisture-proof Box |

Seller: Hench Technology Co., Ltd. (Tianjin, China) |

FITR Moisture-proof Box Feature

The MRD series infrared spectrometer electronic moisture-proof... |

|

|

IR Slide sample holder HW-15/16 |

Seller: Hench Technology Co., Ltd. (Tianjin, China) |

Instrument model:HW-15/16

Range of application:Silicon, plexiglass plate clamping

Fixture mater... |

|

|

Manual digital display button battery sealing machine YP-2NS |

Seller: Hench Technology Co., Ltd. (Tianjin, China) |

Manual digital display button battery sealing machine, small in size and light in weight, can be ... |

|

|

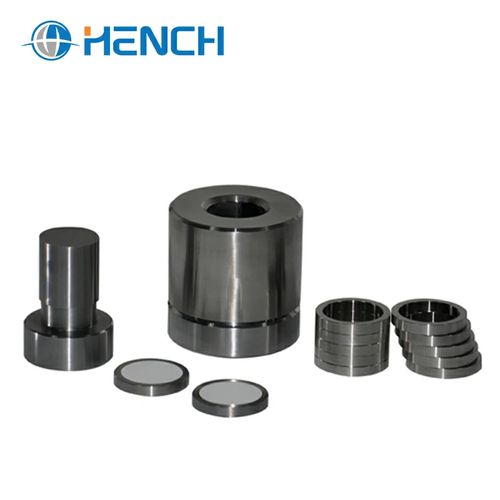

Solid battery die HMN-PG Solid battery die |

Seller: Hench Technology Co., Ltd. (Tianjin, China) |

The die material is made of PEEK and ceramic core, and the diameter can be customized as per requ... |

|

|

Fluorescent special steel ring die 40/32mm HMP |

Seller: Hench Technology Co., Ltd. (Tianjin, China) |

The steel ring dieis used for shaping the samples in X-ray fluorescence spectrometers. A stainles... |