Harmonic Drive Solution

Laifual Harmonic drive (strain wave gear, harmonic gearbox, harmonic reducer) mainly consists of three parts. Which are wave generator, flex spline, cicular spline. Our harmonic drive has the characteristics of zero-backlash, low-temperature rise, low starting torque, high reliability, high load capacity, long lifetime, big speed ratio, small size, etc. Laifual drive is a top manufacturer for harmonic drive. With more than 10 years R&D experience. Supplied harmonic drive to many robotic & automation customers.

LS Series Harmonic Drive Solution

LSS High Precision Harmonic GearboxDesign

Laifual Drive adopts our newest developed 'LS' tooth profile, which improves harmonic reducer's comprehensive performance a lot.

LSD Shorten Thin Harmonic Drive Gear Box

LSD series is a newly developed strain wave gear/drive based on the LSS series to fulfil the needs of the current market.

LSG High Torque Harmonic Drives

Laifual Drive adopts our newest developed 'LS' tooth profile, which improves harmonic reducer's comprehensive performance a lot.

LSN Light Weight Harmonic Drives

Laifual Drive adopts our newest developed 'LS' tooth profile, which improves harmonic reducer's comprehensive performance a lot.

LFS Ultra Flat Harmonic Gearbox

LFS series-this harmonic actuator is a combination product that is lightweight and ultra-flat. It uses cross-roller bearing.

LHT High Precision Harmonic Gearbox

LHT Series use hat type flexspline. We can divide LHT series into 5 versions, LHT-I, LHT-II,LHT-III,LHT-IV and LHT-V.

LHD Shorten Thin Harmonic Gearbox

LHD series's flex spline is a flanging ultra-short tube structure. LHD-I's axial length shortens 50%, LHD-III shortens 15%.

LHG High Torque Harmonic Gearbox

LHT Series use hat type flexspline. We can divide LHT series into 5 versions, LHT-I, LHT-II,LHT-III,LHT-IV and LHT-V.

LHN Light Weight Harmonic Drives

LHT Series use hat type flexspline. We can divide LHT series into 5 versions, LHT-I, LHT-II,LHT-III,LHT-IV and LHT-V.

Harmonic Drive Reducer Working Principle

As a reducer, the china harmonic reduceris often in status as the wave generator drives, the circular spline is fixed, and the flex spline is output end.

When the harmonic wave generator is put inside of the flex spline, the flex spline is forced into an elliptical shape causing the flex spline teeth to engage with the tooth profile of the circular spline along the major axis of the ellipse, with the teeth completely disengaged across the minor axis of the ellipse.

The rotation of the wave generator makes the flex spline deform continuously, the teeth change operating state in the process of engagement and disengagement, thus the power harmonic drive transmission between wave generator and flex spline is realized.

Characteristics of Harmonic Gear Reducer

High accuracy

A good percentage of harmonic gear reducer's teeth are meshed at all times and are engaged at two zones 180 degrees apart. This means influences of tooth pitch errors and accumulated pitch errors on rotational accuracy are neutralized, which assures high positional and rotational accuracy.

High speed reduction ratio

A harmonic gear reducer has high single-stage reduction ratios also known as harmonic drive gear ratio or harmonic drive ratio of 1/30-1/500. Three basic components along same axle without complex structures can provide high reduction ratios.

High torque capacity

Each tooth subjected to a negligible amount of force yet provides a high torque capacity because of the way the teeth come into contact with each other and because a good percentage of the teeth in the flex spline is engaged at all times.

Small-sized and light weight

While being less the size of conventional gearing mechanisms and less the weight, the strain wave reducer provides the same levels of torque and speed reduction ratios as its conventional counterparts enabling machinery and equipment to be made smaller and lighter.

Superior efficiency and long life time

As a professional harmonic drive gearbox company and strain wave gear manufacturer in China, Laifual Drive produces harmonic drive reducers with superior harmonic drive efficiency and long service time.

Quiet and minimal vibration operation

Laifual Drive's harmonic drive reducers also operate with quiet and minimal vibration.

Harmonic Drives Uses

Harmonic drive reducers (also known as strain wave gearbox/reducer) are increasingly widely used in aviation, aerospace, energy, navigation, shipbuilding, bionic machinery, commonly used ordnance, machine tools, instruments, electronic equipment, mining and metallurgy, transportation, lifting machinery, petrochemical machinery, textile machinery, agricultural machinery and medical equipment and other aspects, especially in the servo system with high dynamic performance, the superiority of harmonic gear drive transmission is better showed.

Cycloidal vs Harmonic Drives

Cycloidal reducer:

Cycloidal reducer is used for the three joints of the robot with large torque: leg, waist and elbow and for the industrial robot with large load where cycloidal reducer is used in one, two and three axes. Compared with the harmonic gear drive, the key of the cycloidal reducer lies in the processing technology and assembly technology. Cycloidal reducer has higher fatigue strength, better rigidity and longer life. Its motion accuracy will not be significantly reduced with the increase of usage time. The disadvantage is that it is heavy in weight and large in size.

Harmonic drives:

Harmonic drives are usually used for industrial robots with small loads or several axes at the end of large robots. Harmonic drive gearbox is a kind of harmonic drives, which includes harmonic accelerator and harmonic reduction gear. The harmonic reducers mainly includes: rigid wheel, flexible wheel, bearing and wave generator, all of them are indispensable. The characteristics of harmonic drive gearbox used in small robots are small size, light weight, large carrying capacity, high motion accuracy, and large single-stage transmission ratio.

Both cycloidal reducer and harmonic reducersare internal gearing with small tooth number difference. The difference is that a key gear in the harmonic is flexible. The key gear needs to be repeatedly deformed with high speed, so it is relatively fragile, and its bearing capacity and life are limited. Cycloidal reducer usually uses cycloidal pinwheels. Harmonics used to use involute tooth shape. Now some harmonic gearbox manufacturersuse double arc tooth shape, which is much more advanced than involute tooth shape.

Thanks to years of R&D experience, the precision harmonic drives produced by our company have made major breakthroughs in various special properties. Our harmonic drive gearboxs have the characteristics of low temperature rise, low starting torque, high reliability, high precision, high torque, high rigidity, light weight, long life, large speed ratio and small volume. They can be used in batches in industrial robots, service robots, medical equipment, high-precision automation equipment and other fields. What's more, we also provide custom services, so feel free to contact us if you have any need.

Composition of Harmonic Gear Reducer

Harmonic gear reducer has three basic components:a wave generator,a flexspline and a circular spline.

01Wave Generator

Harmonic gear reducer is made up of a ball bearing and an elliptical cam. The harmonic drive wave generator is usually attached to the input end, the inner ring of the harmonic drive bearing is fixed around the cam causing the outer ring of the bearing deforms to an elliptical shape.

02Flex Spline

It is an elastic thin-walled component with gear teeth on the outer surface. Harmonic gear reducer is usually fitted to the output end.

03Circular Spline

It is a rigid steel ring with internal teeth. Harmonic gear reducer usually has two more teeth than the flex spline, and generally mounted onto a housing.

Send product request

Other supplier products

| Harmonic Gearbox | Laifual adopts our newest developed "LS" tooth profile, which improves harmonic reducer's comprehensive performance a lot. Compared to the original... | |

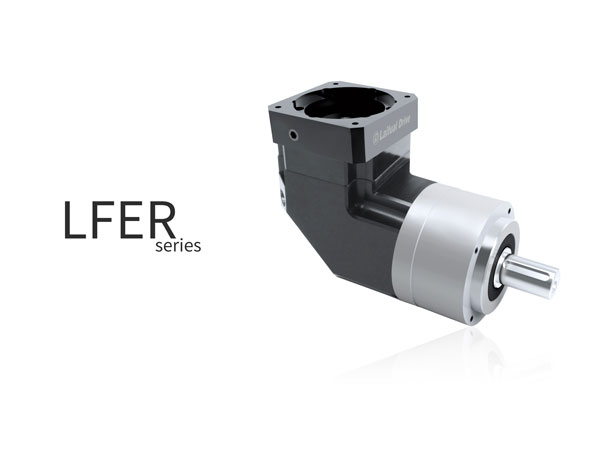

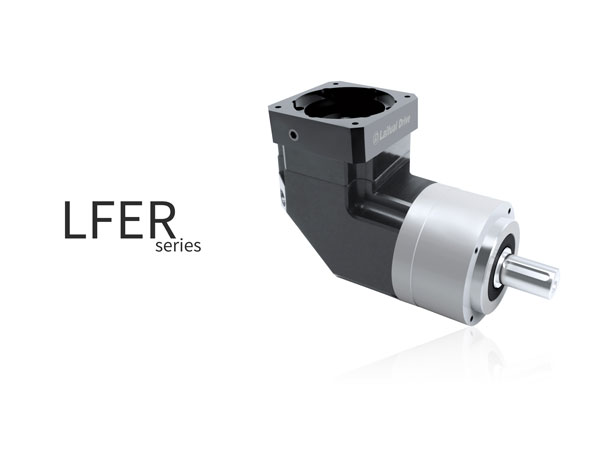

| LFER Right-angle Series Planetary Gearbox | A high-performance right-angle solution for servo applications that keeps LFER's design and characteristics. Specification of LFER Right-angle S... | |

| LFS Ultra Flat Harmonic Gearbox | LFS series- this harmonic actuatoris a combination product that is lightweight, ultra-flat. It uses cross-roller bearing. LFS integrated series-... | |

| LFER Right-angle Series Planetary Gearbox | Zhejiang Laifual Drive Co., Ltd. is a professional harmonic drive manufacturers. We provide LSD Shorten Thin Harmonic Gearbox, LFS Ultra Flat Harmo... | |

| LFB Concentric Shaft Planetary Gearbox | LFB Powerful tool in precision positioning with a backlash of less than 0°03' Reduction Ratio of this planetary gear shaft: 1/3-1/100 Ba... |

Same products

| gearbox spare parts- slow speed shaft | Seller: CITIC IC | We CITICIC mainly supply precision mechanical components and large customized spare parts manufac... | |

| Gearbox 5M for JMC1030 ISUZU NKR NHR | Seller: Shandong Yuchung Power Co., Ltd | Item Name gearbox Applicable Models JMC1030 NKR NHR Code And ... | |

| Cast Grey Iron Gearbox Housing | Seller: Baoding Guokun Export and Import Trading Co., Ltd | Baoding Guokun Machinery Co., Ltdand Baoding Guokun Export and Import Trading Co., Ltd are locate... | |

| Industrial Gearbox | Seller: Baoding Guokun Export and Import Trading Co., Ltd | Baoding Guokun Machinery Co., Ltdand Baoding Guokun Export and Import Trading Co., Ltd are locate... | |

| Precision Plastic Gear Spur Nylon Plastic Gears Sets Plastic Gear Box | Seller: Seitz(Changzhou )Motion Control System Co., Ltd. | Our company specializes in the production of precision gears, precision injection molds, and the ... |