Floating Seal Installing Tools

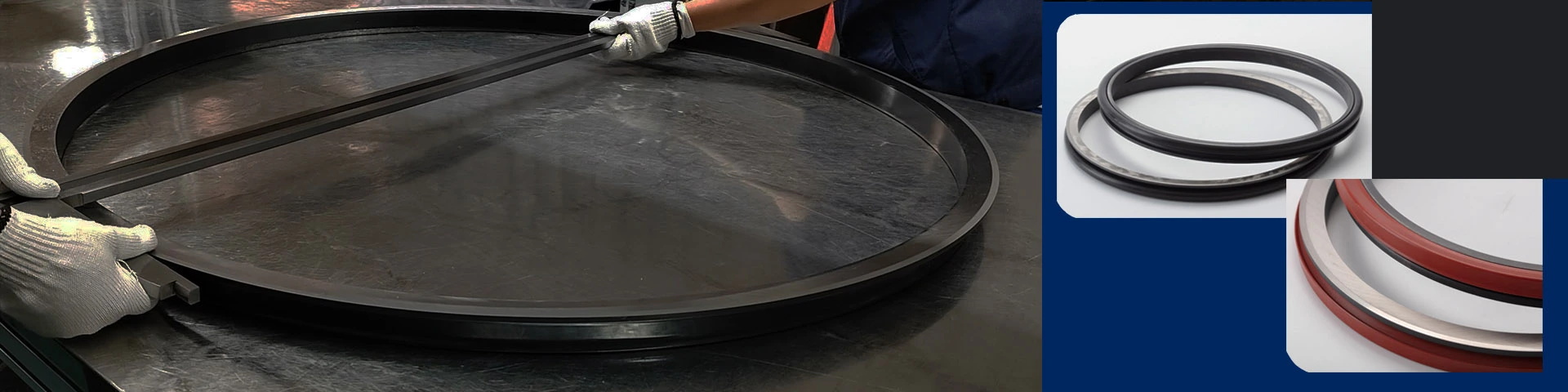

Duo cone seal installer tooland suitable installation procedure are highly recommended for series production and maintenance work. Installation process has a significant impact on seal performance, and diameters up to 1105mm installation tools are available for different mechanical face seals.

Before installation, arrange a cleaned seal, o-ring & housing and free from any mechanical damage and dent. Cleaning the seal using lint free wipe and ensure the seal face be thoroughly cleaned and no fine particles of dust should remain on it.

Place the o-ring on the metal seal ring at the bottom of the seal ring ramp and against the bottom of the seal ring ramp and against the retaining lip and then check it is properly sleeved. Make sure the o-rings are straight on the rim and not twist or squeeze.

Engage the lip of the duo cone seal installation toolbetween the gap of o-ring and seal face inside the circular guide way groove of the tool, and bring the edges of clamp close to each other.

Press the seal ring into the housing like a snap fastener, and press the fixture with even load on the guide plate. Small rings can be manually fixed, however for big rings apply even and gentle pressure around the rim of guide plate using wooden mallet.

Ensure that afterwards the housing face is parallel to the seal face, and o-rings must not undulate in the housing bore or kink and bulge out of the bore. Ensure the clearance between the seal ring housing bores with FUYOTE engineer.

Do not use sharp instruments in floating seal installation. Inappropriate tool cause irreversible damage of metal ring's sealing face. Because mechanical face seals are high precision product, especially the contact band, tools must be used in installation. We recommend the use of installation tools to ensure a proper installation of o-rings. If improperly installed, twist on o-rings might lead to uneven stress and creep down from the metal ring. Eventually cause early failure.

Keep the floating seal in the original packaging until installation, in case dust will get inside the seal before installation. Fine-finished seal faces of the metal seal rings and the o-rings need to be carefully protected from damage and contamination.

The seal housing which contact the rubber o-rings need to be clean and free from machining debris before installation. This should be done using a lint free wipe. Remove the foreign material from the o-rings, ramps and the lips of both seal rings.

Use alcohol to clean the parts instead of any other oil that leaves oil film or do not evaporates. Only use lint free wipes or cloths, and never use tissue paper or cotton waste.

O-rings cannot be used with blow holes or damages. And also cannot be twisted inside housing.

Do not use sharp tools to locate o-rings and hammer on sealing surface.

Check for sealing edge free from dirt, dust, and hair. Keep the sealing surface clean thoroughly before installation, and never allow sealing surface be dirty, keep it be cleaned well before assembly.

After compete the final assembly of the unit, make sure both seals are in the correct hosing position, due to high impact can scratch or break the seal components. A new set will have to be installed even the wear limit is not yet reached, when the seal set is taken apart in the course of repairs.

We provide duo cone seal installation tool for sale, floating seal assembly, duo cone seal installer, duo cone seal installation, floating seal hs code, etc. For more information, please feel free to contact us!

Send product request

Other supplier products

| Axle Floating Seal Final Drive | Floating seals, also known as mechanical face seals or duo-cone seals, are commonly used in axle applications, including steering drive axles and f... | |

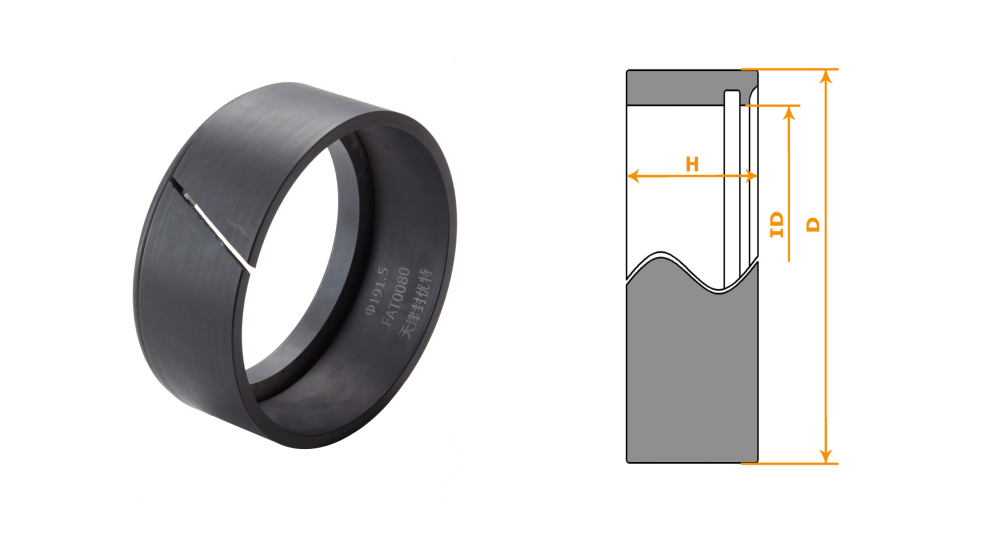

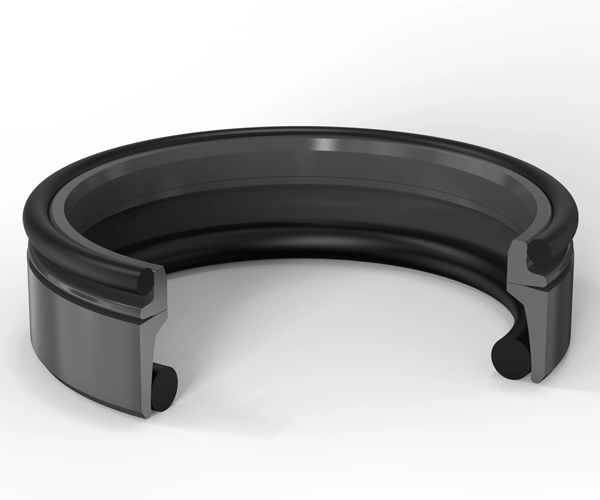

| DF Floating Seal | Heavy Duty sealconsists of two separate metal seal rings and two square o-rings that provide elastic compression within housing bores and it also c... | |

| DO Floating Seal | Duo cone sealalso called O-ring face seal and DO floating seal. DO floating seal consists of two separate metal seal rings and two o-rings which pr... | |

| OEM | OEM and ODM are offered in fuyote. Fuyote is a 30 years floating seal manufacturer in china. Multiple types of floating seals can be chosen which c... | |

| Construction Machinery Floating Seals | Construction machinery floating seals, also known as mechanical face seals or duo-cone seals, find various applications in construction machinery t... |

Same products

| Tracked Vehicles Final Drive Seal | Seller: Tianjin Fuyote Technology Co.,Ltd. | Travel final drive floating seal kits, also known as undercarriage part floating seals, are essen... | |

| Floating Seal Installing Tools | Seller: Tianjin Fuyote Technology Co.,Ltd. | Duo cone seal installer tooland suitable installation procedure are highly recommended for series... | |

| Floating Seal | Seller: Tianjin Fuyote Technology Co.,Ltd. | Floating Seal Types DO Floating Seal Duo cone seals are made by casting. The largest size of ... | |

| DO Floating Seal | Seller: Tianjin Fuyote Technology Co.,Ltd. | Duo cone sealalso called O-ring face seal and DO floating seal. DO floating seal consists of two ... | |

| DF Floating Seal | Seller: Tianjin Fuyote Technology Co.,Ltd. | Heavy Duty sealconsists of two separate metal seal rings and two square o-rings that provide elas... |