SMC Cable Braket

The SMC cable bracket is a combination consisting of a cable bracket, a post and a fixed pin. The material of the column and the pin is also made by the high temperature pultrusion of the FRP composite. The column can be arbitrarily cut length according to the needs, the height of the layer is adjusted, and the assembly is free. The cable bracket has various specifications to meet different lengths and load requirements.

Light weight, high strength, aging resistance, UV protection, more importantly, 1 mm can withstand voltages above 10,000 volts, it is a good insulation material.

Features: high insulation, chemical resistance, high fire resistance, good water resistance, accurate size, stable working performance, light weight, high strength, acid and alkali resistance, waterproof, moisture-proof.

SMC Cable BraketSpecification

|

Project |

SMC Cable Braket |

Galvanized angle bracket |

|

Density (g/cm3) |

||

|

Specific strength |

167 |

90 |

|

Corrosion resistance (80°/100h) |

||

|

Insulation strength (kv/mm) |

Conductive |

|

|

Flame retardancy |

meets the FH-1 |

-- |

|

Water resistance (%) |

-- |

|

|

Corrosion resistance |

Corrosion、acid、alkali、salt resistant |

Corrosive, easy to rust |

|

insulation |

insulation |

Conduction |

|

Mechanical strength |

Top force 2.5kN deflection 1.0cm |

Top force 2.5kN deflection 1.2cm |

|

Lateral force 0.5kN |

Top horizontal offset 7cm |

Top horizontal offset 7cm |

|

Weight |

light |

weight |

|

Eddy current effect (loss) |

no |

Large loss |

|

Manufacturing process is difficult |

easy |

Many processes and long cycle |

|

Cable outer sheath scraping test |

No visible damage |

There is a little visible damage |

|

Raw material |

Cheap, resource-rich |

More expensive, partially imported |

|

Maintenance |

Free maintenance |

5-7 years need to be repaired once |

|

Installation process is difficult or easy |

Short time and easy to install |

Long time, difficult to install |

|

Use life |

30 years |

10 years |

Zhejiang Aobang Technology Co., Ltd.is one of the most professional sheet molding compound manufacturersin China, and we hope to gain recognition and support from our customers and to develop mutual cooperation.

Send product request

Other supplier products

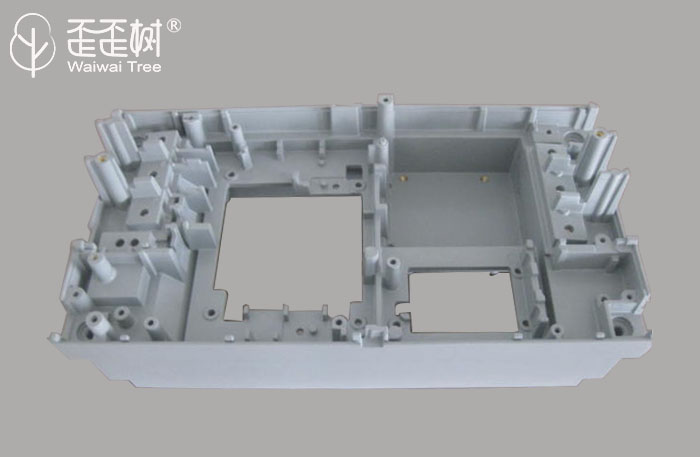

| SMC/BMC Framework | SMC/BMC Framework Description Strong plasticity, precise size, high insulation and high temperature resistance. BMC molded framework is suitabl... | |

| SMC Cable Braket | The SMC cablebracket is a combination consisting of a cable bracket, a post and a fixed pin. The material of the column and the pin is also made by... | |

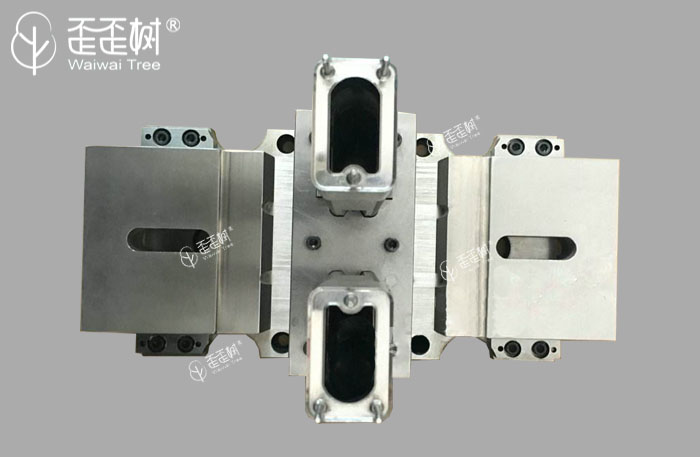

| BMC/SMC Mould | BMC/SMC Moulding Description: We mainly use SMC injection moldingand pressure molding as the methods. When designing the flow channel and parting s... | |

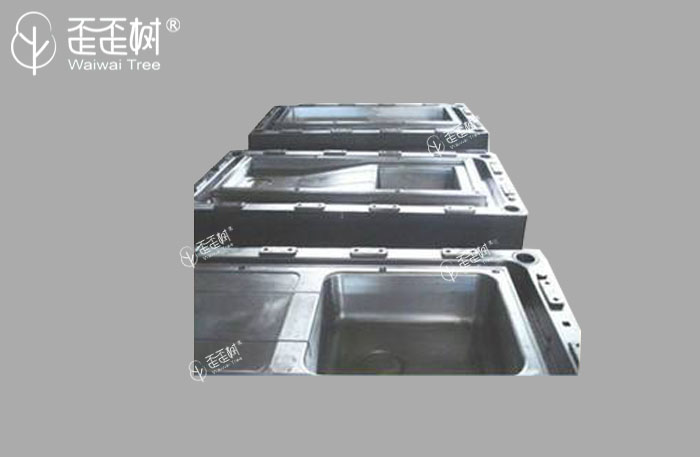

| Household Mould 1104 | Household Mould Description Mainly for pressure molding, the cavity pressure should be considered as small as possible when designing the parting ... | |

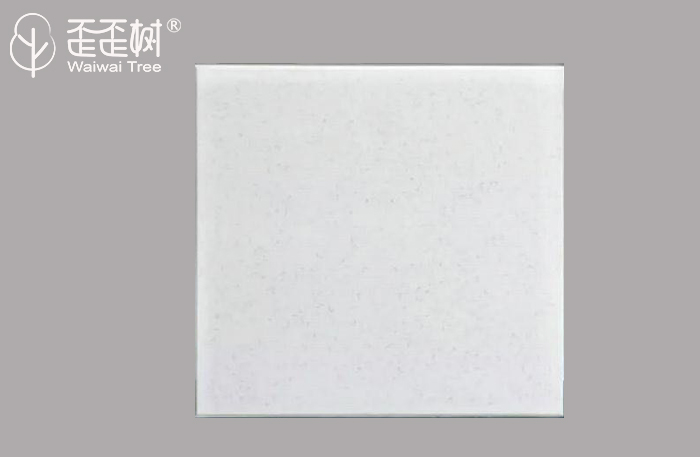

| BMC, SMC, GRP, GFK Building & Decoration Materials | Building decoration materials, also known as building finishing materials, refer to the materials laid or painted on the surface of buildings to de... |

Same products

| Motorcycle Body and Frame Plastic Mold | Seller: Taizhou Huangyan Jingnan Moulding Co., Ltd. | As a key component mold professionally manufactured by Jingnan Mould, motorcycle body frame plast... | |

| For 2017 Audi A7 Rear Bumper Mould | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Mould Name Audi A7 Car Bumper Mould Material PP+EPDM(Contraction: 1, 5%) Bumper Size 1800*510*460... | |

| For Mercedes-Benz-C-206 Modified Bumper Mould | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Taizhou Huangyan Chenpeng Mold Co., Ltd. is a professionalwholesale Mercedes-Benz-C-206 Modified ... | |

| Front Bumper Lower Lip Mould For 2021 Honda CRV | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Introducing the for 2021 Honda CRV Front Bumper Lower Lip Mould: Elevate Your Driving Experienc... | |

| Bottle cap mold | Seller: Taizhou Huangyan Yongsheng Mould Co., Ltd. | Taizhou Yongsheng Mould Co., Ltd. can produce cap moulds ()within 64 cavities. The hot runner or ... |