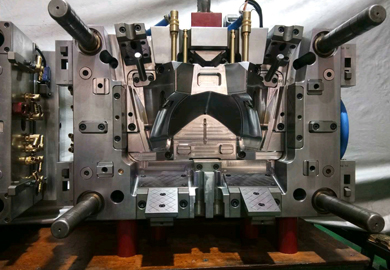

Electronics Product Mould

Decades of accumulation of mould manufacturing technology have witnessed the popularity of electrical plastic molding products.

The in mould electronicshas been widely applied to various industries. As a result, electronics injection mold manufacturers have been talking about rapid prototype plastic molding that will change electronic devices.

Features of Electronics Product Mould

Since the popularity of electrical plastic moulded products, why do people choose such precision plastic injection plastic mold technology? Here are some major features of electronics product mould.

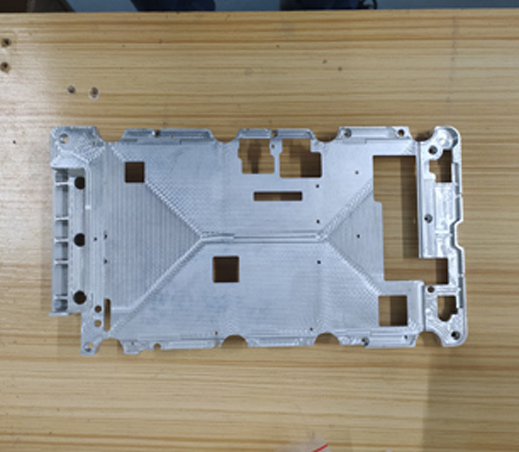

Reduction in the complexity of plastic products;

Automation of assembly processes;

Integration of electronics into products that have geometrically complex 3d printing shapes;

Reduction in thickness and weight;

Increased functionality;

More durable electronics can be manufactured.

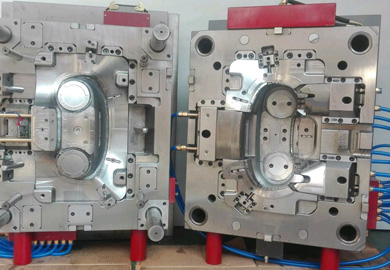

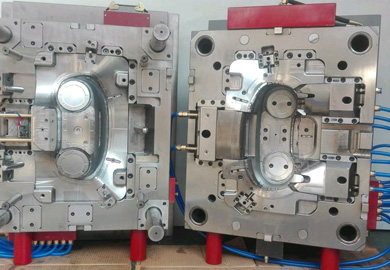

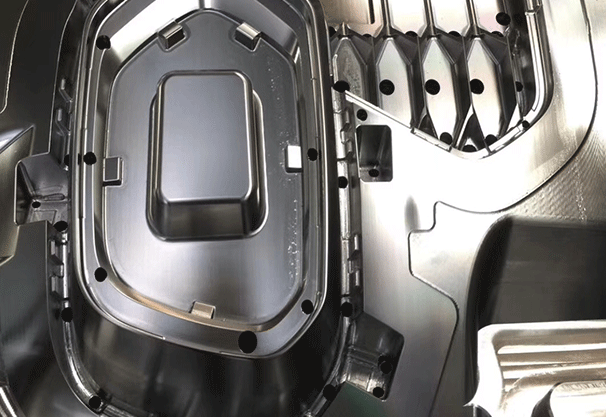

The Specification of Automotive Product Mould

|

Part material |

ABS |

|

Cavity |

1 |

|

Mould accuracy |

+ / - 0.02 |

|

Mould steel |

|

|

Mouldbase steel |

|

|

Mould life |

100W |

|

Mould standard |

HASCO |

|

Mould structure |

2 slides |

|

Exporting country |

UK |

|

Leadtime |

6 weeks |

|

Mould quality customer satisfaction |

98% |

|

FAI pass rate |

96% |

|

Project cooperation service customer satisfaction |

98% |

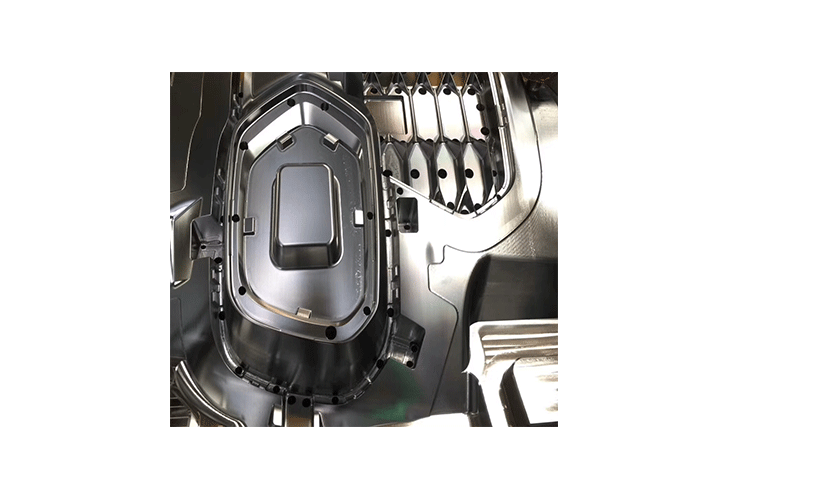

How does Electronics Product Mould Work?

The desired pattern of plastic insert molding is finished through the screen or digital printing in the beginning. Then it is placed in a mold tool. After that, drying polymer pellets are poured into an electrical plastic molding machine. They are melted and pressurized into the mold. The form of plastic injection molding product is filled with polymer, and the printed label is "glued" to the plastic enclosure. At the output, when we open the mold, we get a ready-made part of the plastic enclosure with integrated graphics.

Send product request

Other supplier products

| Die Casting Mould | Die casting mould is a method of casting liquid die forging. It is a process completed in a special die casting moulding machine. The major adva... | |

| Medical Equipment Mould | Medical products include syringes, and internal and external parts of medical equipment. Features of medical device injection molding Our company ... | |

| Prototype Part | GM-TECH, a plastic injection manufacturer, has been manufacturing tools for injection molding of plastics for various industries for more than 10 y... | |

| Plastic Injection Mould | As a China injection mould factory, GM-TECH is mainly engaged in the production of high-precision injection mould production plants. And the produc... | |

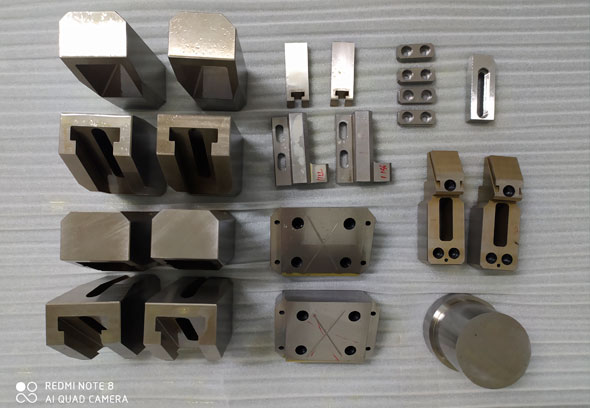

| Mould Spare Part | Plastic molded productsinclude single section shoot, double section shoot, double section shoot, flat tip, flat tip, positioning column, plastic mo... |

Same products

| Mold Components | Seller: Packson Mold Co.,Ltd | We provide custom made plastic parts-Sliders, inserts, lifters, blocks, ejector pins, and other m... | |

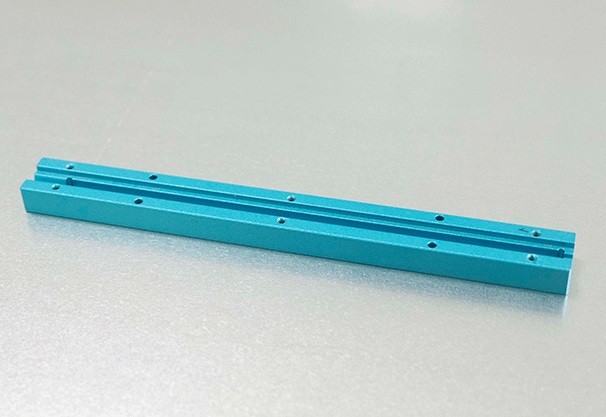

| Custom Metal Machining Parts | Seller: Packson Mold Co.,Ltd | Packson provides our customers a various CNC machining services to our customers, including milli... | |

| Clean Room Injection | Seller: Packson Mold Co.,Ltd | Packson - Medial Injection Moulding Cleanroom Expert Packson specializes in delivering top-notch ... | |

| Medical Plastic Injection Molding | Seller: Packson Mold Co.,Ltd | Packson - Medical Plastic Injection Molding Expert Packson sets itself apart from other medical i... | |

| CNC Metal Machining Parts | Seller: Packson Mold Co.,Ltd | Packson is a contract manufacturer specializing in CNC Milling, CNC Turning, CNC Drilling service... |