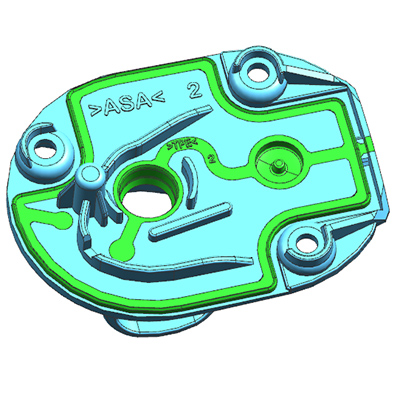

Over-Molding Parts

Custom Mold & Design

The overmolded partsis a process that can bond different materials by the injection moulding.

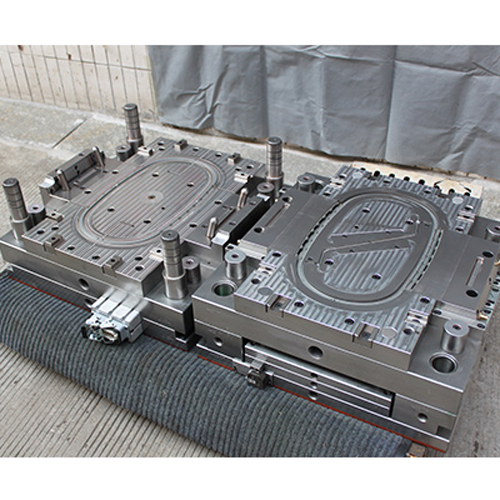

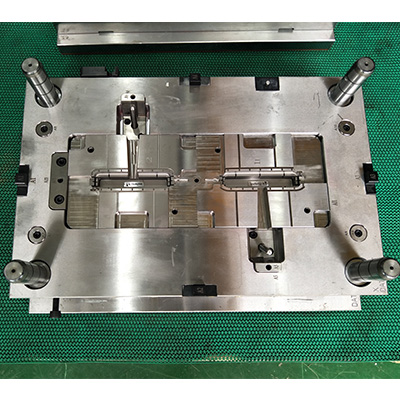

Plastic injection overmoldingin HanKing is a technology to combine two different moulds while we called the combination of different resins in one mould as two-shot. Knowledge of plastic resin compatibility is very crucial for over-molding, HanKing's expertise assure the performance of the over-molding part is bonded strong.

There are many factors in the selection of over-molding resins, it depends on the properties of the basic resin and on the other hand on the application properties. Specifically, there are the following:

Corrosion resistance.

Flame retardant (in line with ecological and environmental requirements). The eco-friendly logo is a sign that the product meets environmental and social standards.

Wear resistance (to avoid sink or stripping).

Shore hardness (in accordance with soft feeling or other requirements).

Impact resistance (in accordance with structural requirements).

Melting point (Meets application temperature requirements and does not soften or deform).

Bonding method (mechanical interlocking is formed when the two materials do not match, and chemical bonding is formed when the two materials match).

In general, the matching material should have similar chemical properties or contain matching composite elements. When the basic resin does not match the covering material, it usually only forms a mechanical interlocking effect, not a chemical bonding.

Soft plastic resin can be molded with different materials, but it is more limiter and stricter when hard plastic is over-molded with other hard resin.

It is acceptable to over-molded a plastic part with two hard resins in small areas, but it cannot be used in large areas and designed the second hard plastic over-molded the first hard resin as a closed ring.

From design work as mould base selection, wall thickness, filling balance, ejector balance, even venting to subsequent manufacturing process, HanKing will consider all the details in order to make a mold that will satisfy the customer.

As one of overmolding companies, we have types of molding plastic parts at homefor sale, if you have needs, please contact us.

There are many china injection molding suppliersin China, but we are one of the best choices for you.

Send product request

Other supplier products

| Industrial Molding Parts | We are one of theresponsible china injection molding suppliersand have experience in supplying custom plastic injection mouldingservice for many ye... | |

| Home Appliance Mould | Home Appliance Mould Embroidery Machine Frame Mould 4937-2 Plastic frame for a multi-needle embroidery machine. Mould Name: Embroidery Machine Fra... | |

| Plastic Injection Moulding Die Makers | Plastic Injection Moulding Die Makers Plastic mould die makerin China Focus on all kinds of mould development, various plastic mold manufactu... | |

| Prototype Mould | Soft Prototype Mold Prototype moldis a kind of test mould before mass production mould, customer make test mould for design verification, Product ... | |

| Two Shot Molding Parts | Two Shot Tool Construction Part two shot tool construction saves the injection machine quantity and plant area, lower the labor cost and minimize t... |

Same products

| Motorcycle Body and Frame Plastic Mold | Seller: Taizhou Huangyan Jingnan Moulding Co., Ltd. | As a key component mold professionally manufactured by Jingnan Mould, motorcycle body frame plast... | |

| For 2017 Audi A7 Rear Bumper Mould | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Mould Name Audi A7 Car Bumper Mould Material PP+EPDM(Contraction: 1, 5%) Bumper Size 1800*510*460... | |

| For Mercedes-Benz-C-206 Modified Bumper Mould | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Taizhou Huangyan Chenpeng Mold Co., Ltd. is a professionalwholesale Mercedes-Benz-C-206 Modified ... | |

| Front Bumper Lower Lip Mould For 2021 Honda CRV | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Introducing the for 2021 Honda CRV Front Bumper Lower Lip Mould: Elevate Your Driving Experienc... | |

| Bottle cap mold | Seller: Taizhou Huangyan Yongsheng Mould Co., Ltd. | Taizhou Yongsheng Mould Co., Ltd. can produce cap moulds ()within 64 cavities. The hot runner or ... |