Home Appliance Mould

Home Appliance Mould

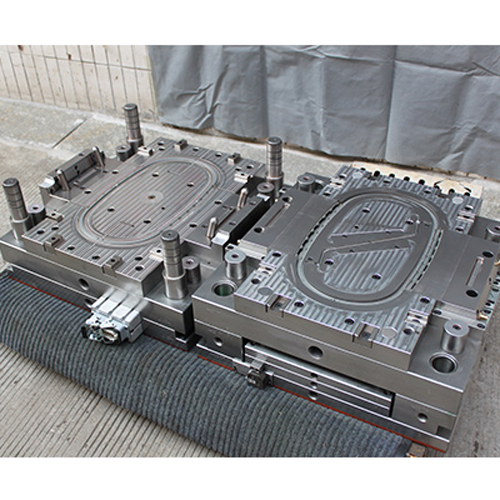

Embroidery Machine Frame Mould 4937-2

Plastic frame for a multi-needle embroidery machine.

Mould Name: Embroidery Machine Frame Mould

Part Material: Pa 66 GF50%

Product Description Large Embroidery hoop frame

Mould Cavity: 1 Cavity

Mould Size: 450*650*410 mm

Mould Cavity Steel: 8407

Mould Injection System: Cold runner/ tunnel gate

Mould Ejection System: ejector pin

Mould Cycle Time: 55's

Mould Life Cycle: 500,000

Lead Time: 50 working days

Mold Export To: Europe

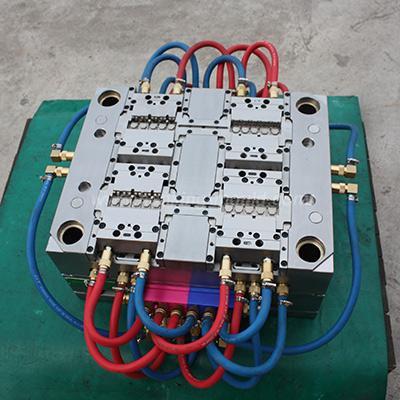

Sewing Machine Frame Mould

Large plastic frame plastic injection mould, suited for oversize embroidery projects.

Mould Name: Embroidery Machine Frame Mould

Part Material: Pa 66 GF50%

Product Description Large Embroidery hoop inner frame

Mould Cavity: 1 Cavity

Mould Size: 400*600*380 mm

Mould Cavity Steel: 8407

Mould Injection System: Coldrunner/ tunnelgate

Mould Ejection System: ejector pin

Mould Cycle Time: 55's

Mould Life Cycle: 500,000

Lead Time: 50 working days

Mould Export To: Europe

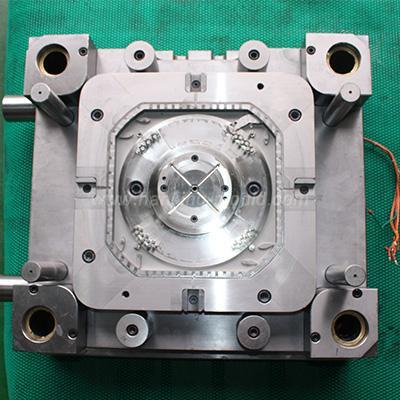

Coffee Machine Spare Part Mould 4913-5

Home Appliance Mould for the coffee machine, Hanking Mold have experience in different type Coffee Machine spare part moulds, some large part as housing, and small part is the tiny plastic filter.

Mould Name: Coffee Machine Spare Part Mould

Part Material: POM

Product Description: Plastic Cork

Mould Cavity: 2 cavities

Mould Size: 250*300*293mm

Suitable Injection Machine:

Mould Cavity Steel: 2344

Mould Injection System: ejector pin

Mould Ejection System: cold runner

Mould Cycle Time: 28's

Mould Life Cycle: 500,000

Lead Time: 40 working days

Mold export to: Europe

Home appliance mould is also known as household appliance mould which is used to produce plastic parts and components for the household electric appliance.

The household appliance moulds generally include interior plastic parts mold and the exterior plastic housing or case.

For interior parts, dimensional accuracy is the most important, and there is usually no special requirement for appearance, as long as it does not affect the assembly of the products.

For exterior plastic housing or cases, the appearance and size are both important, but the exception is that some housing or cases will go to secondary processing, such as painting, plating etc., so that the injection-moulded exterior housing usually is not required to be high polish, only in some specific areas that affect the subsequent process are high polished.

How to ensure the accuracy of the plastic parts? First of all, to ensure the accuracy of the mould steel dimension. In HanKing, all the dimensions in the molds are within tolerance measured by CMM Zaiss before the moulds are delivered to our customers. As a mold company china, we have good designers with more than 15 years of experience, providing good solutions and professional technical support. When we are designing a house appliance plastic injection mold, we should choose the mould steel by combining the total life cycles and the plastic resin of the part. Make inserts as much as possible for important dimensions or special structure area and some fragile ribs, because the inserts can be replaced and convenient maintenance after a long period of production. And machining by grinder as much as possible, in terms of accuracy, the grinding machine has its' advantage.

Every kind of machine has different advantages, toolmakers should understand the advantages of these devices and make the best use of them to help to make good quality moulds. Another point, keep some clearance for the mould steel is also very critical to get correct dimension parts.

Of course, it is far more than these points to make good quality moulds, please contact us and tell us your needs, we look forward to providing our professional support for your project.

Other supplier products

|

|

ABS Plastic Injection Mold 49443 |

Brief Introduction of Hanking ABS molds

Mould Name: Plastic Injection ABS Molds

Part Material: ABS

Product Size: 172*123 mm

Product Description:... |

|

|

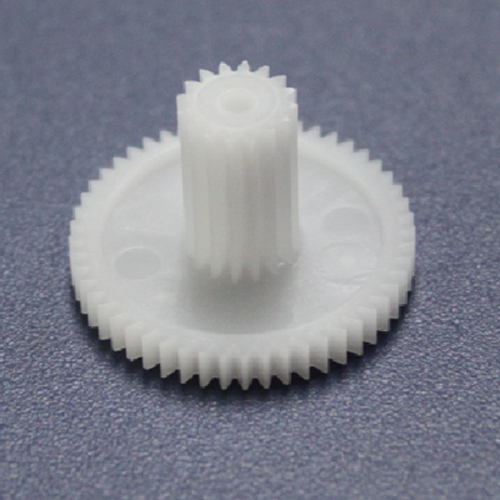

Gear Mold |

Plastic Gear Mold Design 49122 Mould Name: Custom Plastic Gear Mould Part Material: PA6 Product Size: 33*16.5mm Product Description: Plastic Mot... |

|

|

Industrial Mould |

HanKing Mould Enginering Ltd. has industrial molds for sale! Industrial hanking moldis not a mold technology process, but a type of hanking mould t... |

|

|

Automotive Mold |

Plastic Auto Parts Sensor Mould

HanKing Mould produce all different kind fuse and connector for international OEM company, we have a lot of experie... |

|

|

Automotive Molding Parts |

Injection Molding Automotive Parts

Hanking mouldinvolves various automotive injection plastic mold oem, our engineers are familiar with the charac... |

All supplier products

Same products