Insert Molding

Insert molding serviceis one category of injection molding that allows preformed parts or components, usually metal inserts, to be inserted into the plastic molded parts and to have a final product in one-step process. Insert moulding has characteristics as below:

A combination of two parts, preformed components (metal threaded inserts) and plastic molded parts (plastic resin);

One-step process is executed and avoids secondary assembly operations;

Insert the components into the parts to increase the functionality for the whole part.

As a professional china mold manufacturer, Keyplast insert moldingmanufactureralso offer different varieties of injection mold toolings such as two shot molding, overmolding injection molding and materials used in injection moulding according to your different needs.

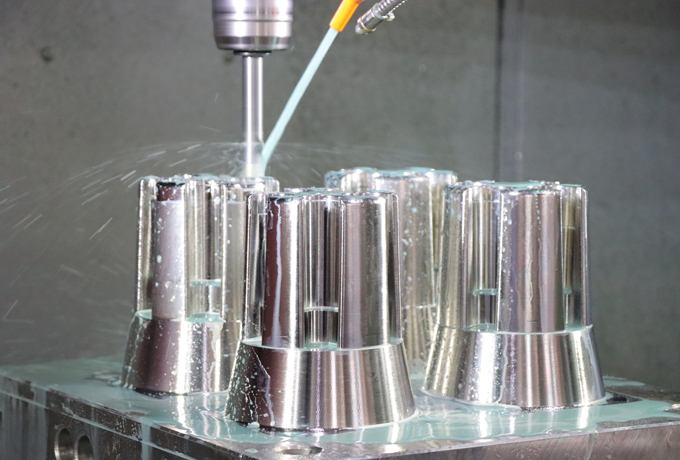

Insert Molding Process

Firstly, prepare the finished molds well with preformed parts, like threaded inserts. Secondly, inject the melted plastic resins into the molds to create a whole part with threaded inserts. After sufficient cooling, the molded parts with threaded inserts will be ejected out. Insert molding process has key factors as below:

Preparation for the inserts

Material selection for the main parts

Melting temperature for injection

Cooling time before moulds open

Testing for the inserted plastic parts

What Is Insert Molding ?

What is insert moulding: Insert molding is a manufacturing process in which a preformed part (usually metal) is remolded using a heated thermoplastic resin to produce a single unit, called metal insert molding. Molded inserts can be simple objects, such as rods, threads, or blades, but they can also be complex.

There are many cases where this manufacturing method is needed to enhance the mechanical properties of plastic parts. The plastic moldingprocess requires very high precision to ensure the correct molding of the final plastic part. Even the slightest deviation can completely destroy the results, so very strict quality control procedures are required. In fact, the insert molding process is closely related to the interface between the machine and the tool. Some high-precision machines can meet even the most demanding requirements of precision and reliability that only insert moulding can meet.

Insert Molding Solutions

As one ofprofessional insert molding manufacturers,Keyplast provides rapid insert molding solutions. To reduce assembly cost, different sizes of metal insert molding can be inserted directly in one step during the insert injection molding process. Before the choice of insert molding, we need to consider several things, including confirmation of the inserted parts, the used materials and part design considerations.

If you are looking for a reliable china plastic supplier, please contact us, and we will be your best partner.

Send product request

Other supplier products

| Injection Mold Design Engineering | Injection mold design engineeringis a procedure at the first stage of injection molding process, which develops the injection mold designs to impro... | |

| Injection Molding Surface Finish | Injection MoldSurface Finish Do not use the finest whetstone, sandpaper, or abrasive polishing paste at the beginning of mold polishing, as you ... | |

| Plastic Injection Mould Tooling | Plastic molds are tools that are matched with plastic mold makingmachines in the plastic processing industry to give plastic products a complete co... | |

| Gardening Injection Molding | Keyplast brings every concept into a reality, not only for every client, but also for our own development in all areas, especially in gardening ind... | |

| Plastic Injection Molding | What is plastic injection molding? Plastic Injection molding is a molding method that combines injection and molding. The advantages of plastic sma... |

Same products

| Motorcycle Body and Frame Plastic Mold | Seller: Taizhou Huangyan Jingnan Moulding Co., Ltd. | As a key component mold professionally manufactured by Jingnan Mould, motorcycle body frame plast... | |

| For 2017 Audi A7 Rear Bumper Mould | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Mould Name Audi A7 Car Bumper Mould Material PP+EPDM(Contraction: 1, 5%) Bumper Size 1800*510*460... | |

| For Mercedes-Benz-C-206 Modified Bumper Mould | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Taizhou Huangyan Chenpeng Mold Co., Ltd. is a professionalwholesale Mercedes-Benz-C-206 Modified ... | |

| Front Bumper Lower Lip Mould For 2021 Honda CRV | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Introducing the for 2021 Honda CRV Front Bumper Lower Lip Mould: Elevate Your Driving Experienc... | |

| Bottle cap mold | Seller: Taizhou Huangyan Yongsheng Mould Co., Ltd. | Taizhou Yongsheng Mould Co., Ltd. can produce cap moulds ()within 64 cavities. The hot runner or ... |