Car Light Mould

Car Light Mould

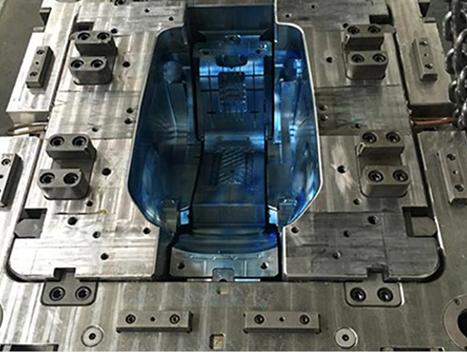

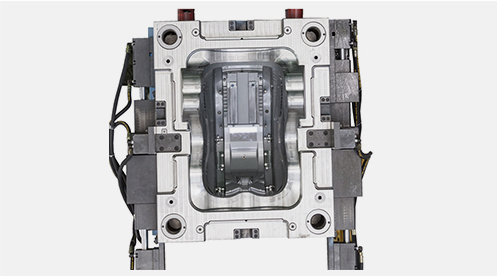

The car headlight mouldplays a vital role in illuminating vehicles, serving as the eyes of cars. It encompasses all the lighting systems employed in automobiles. The design and production of auto lamp mouldnecessitate meticulous attention due to the exacting requirements of automobile light appearance. Transparent and electroplated components constitute several critical parts of these lights. The lamp itself stands out as the most demanding element in the car's aesthetic. The front and rear headlights represent the primary illumination sources for most cars. Lighting configurations differ across various car series, while even within the same series, variations exist based on height configuration. The key components comprising the front and rear lights of a car include left and right lenses, decorative frames, lamp housings, reflectors, among others.

Car Light Mould Appearance Requirements

Lens (Material: Transparent PC): Steel CAV / COR: NAK80 or S136H (HRC33-37), the hardness of the cavity and core is staggered. The product is highly polished, can't pass the whetstone, save the mold to 1000# sandpaper and then polish.

The decorative frame ( Material PBT ): Mold Steel: CAV: NAK80 or S136H (HRC33-37), COR: forged steel HRC31-35, the product is highly polished, can not pass whetstone save the mold to 1000# sandpaper and then polish. The cavity side ( reflective surface) can not be welded.

Reflector (Material BMC): The cavity and core are made of 8407 steel (to achieve a high polishing effect), the cavity steel is HRC46-50, and the core steel is HRC44-48. The cavity side (reflecting surface) is high polished, and can not pass the whetstone, save the mold to 1000# sandpaper and then polish, the core side is generally 600# polished.

Car light Mould Basic Information

Auto Lamp Mould Specification

|

Description |

Automotive lights Injection Mold |

|

Mold base |

LKM; HASCO; DME, etc |

|

Mold cavity&core steel |

P20,2738,718H,738H,NAK80,SKD61,E420,etc. |

|

Nos of Cavity |

Single or Multi |

|

Finish |

Anodized,Polish,Silk-screen,Painting,etc |

|

Hot runner brand |

YUDO, HUSKYFISA, HASCO, MOLD-MASTER |

|

Product material |

ABS,PP,PE,POM,PMMA,PC etc |

|

Mold life |

100k-500k shots |

|

Manufacture time (day) |

30-45 days |

|

Packing |

Vacuum+plywood wooden box |

|

Packing |

Vacuum+plywood wooden box |

Car Light Mould Technology Summary

Plastic features: transparent color, high requirements for the appearance surface, no spots/gate/marks, no bubbles/ fog halo/shrinkage mark/ welding lines, and other forming defects.

In view of the plastic color transparent, the use of an ordinary runner can avoid the plastic color difference, improve transparency, coupled with the plastic surface is not allowed to have gate marks, so use the side gate gating system.

Car light mould adopts the combined cooling system of "vertical cooling water pipe, inclined cooling lines, and splice water well", and the waterway is arranged along the cavity, effectively ensuring the precision of the plastic parts and the labor productivity of the mold. The plastic parts are ejected out by an ejector block, which is not only stable but also leaves no influence on the appearance of the product.

In the molding of transparent mold, the design of the exhaust system is very important, such as poor exhaust, will seriously affect the quality of plastic parts, in view of the product material for PC, exhaust front-end design for 0.02mm, around the product according to CAE analysis of reasonable design exhaust, reduce the bubble or air trapping caused by local burns and other problems during plastic injectionmolding.

Now the price of custom plastic injection moldis reasonable, if you have needs, please contact us.

Send product request

Other supplier products

| Mouse Mold | One computer mouse usually includes these plastic parts: a bottom shell, an upper cover, a middle cover, a wheel, a base of wheel, a frame which co... | |

| Home Appliance Mould | Home Appliance Mould GV Mold has rich experience in home appliance mold(such as television, refrigerators, fans, washing machines, air conditi... | |

| Auto Part Mold | Auto Part Mold With the vigorous development of the automotive industry, plastic auto part moldis also developing rapidly. 90% of auto parts are p... | |

| Car Seat Mould for Kids | Child safety seats are seats specially designed to protect children from injury or death in a collision. The main structure of the child safety sea... | |

| Industrial Plastic Injection Mold | The injection molding part is replacing metal products in many fields of industrial applications to meet the requirement of lightweight industrial ... |

Same products

| Motorcycle Body and Frame Plastic Mold | Seller: Taizhou Huangyan Jingnan Moulding Co., Ltd. | As a key component mold professionally manufactured by Jingnan Mould, motorcycle body frame plast... | |

| For 2017 Audi A7 Rear Bumper Mould | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Mould Name Audi A7 Car Bumper Mould Material PP+EPDM(Contraction: 1, 5%) Bumper Size 1800*510*460... | |

| For Mercedes-Benz-C-206 Modified Bumper Mould | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Taizhou Huangyan Chenpeng Mold Co., Ltd. is a professionalwholesale Mercedes-Benz-C-206 Modified ... | |

| Front Bumper Lower Lip Mould For 2021 Honda CRV | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Introducing the for 2021 Honda CRV Front Bumper Lower Lip Mould: Elevate Your Driving Experienc... | |

| Bottle cap mold | Seller: Taizhou Huangyan Yongsheng Mould Co., Ltd. | Taizhou Yongsheng Mould Co., Ltd. can produce cap moulds ()within 64 cavities. The hot runner or ... |