Adaptor

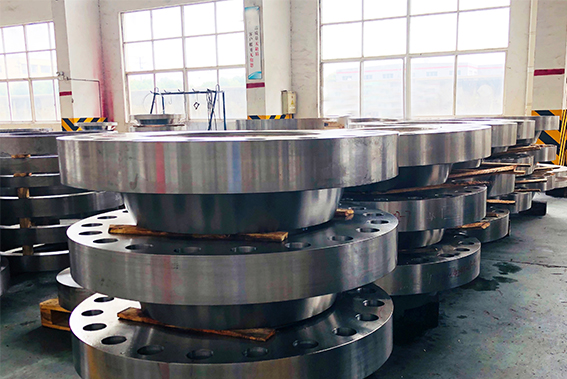

Adapter is one of the most important part of G.E.T system, especially the cast lip system. Either made by casting or forging, an adaptor installed between the lip and the tooth. It's nose and pocket support the main structure.

WALKSONmainly focus on providing big size cast adaptors, components made by casting. The main material for this adaptor is low alloy high strength steel which contains chromium, nickel, and molybdenum. The typical weight of them range from 100kg to 300kg. After quench and temper, the final microstructure is mainly tempered martensite. Its mechanical property result can achieve 1200 tensile strength with 25 J/cm2 impact energy at ambient temperature and hardness of the casting surface is between 380~420 HBW.

WALKSON Ensures High-quality Adapter

WALKSON has an incredibly good control of the manufacture processes which is the key factor that we can provide high quality cast adaptor. The main measures to ensure good products are made as below.

Casting methods design is the first important step to achieve a good quality adaptor. As WALKSON has very experienced methods engineer assisted with the FEM software such as Magmasoft / Intecast. We will conduct FMEA at prototype stage to avoid most of the casting defects that may happen during the following manufacture process.

Following the methods designing is pattern tooling designing, the designing of the pattern tooling also has a big influence on the final casting quality, such as the core print draft, the contraction scale, good pattern tooling designing can make sure a clean mold cavity is obtained after close and accurate nose and pocket size and location are achieved.

The key to the molding process is to make sure the shopfloor operation is conducted strictly according to the methods card. Such as using the correct sleeve/chill or isotile brick, as this has a direct influence on the adaptor's inner quality. The paints baume degree and paint coating thickness control is important, the surface quality rely a lot on them.

During melting process, the key control point is online element analysis, WALKSON’s foundry has spectrograph and can adjust all the element to the required value. Wire injection machine with CaSi wire is highly practical for deoxidation. And Zirconium is a good option if the AL level is considered. At last are the tapping temperature and pouring temperature and pouring time control. WALSKON use bottom pour ladle which is also big advantage to make clear casting.

After knock-out, pneumatic knock-off gun is used to knock off the feeders, ingates and runner bars. Normally the knock-out temperature is recommended to below 50 ℃. On one hand this can improve the working efficiency, on the other hand it can reduce the cracks caused by traditional hot cutting. On one hand this can improve the working efficiency, on the other hand it can reduce the cracks caused by traditional hot cutting.

During the heat treatment stage, the heat treatment tray, the loading methods, the capacity of the quench tank, the speed of agitation system, the heat quenching temperature and the transfer timing are extremely sensitive as those factors affect the final mechanical property. WALKSON has very good heat treatment facility, the uniformity of the oven we can control is within +/- 2 ℃.

WALKSON also has a lot of experience in the adaptor gauging designing and manufacture process, which is can make sure the batch production complies with dimension requirement.

Why Choose WALKSON Adapter

WALKSON is very experienced in making high-quality adaptors. We have been supplying adaptors to mine sites in European, Africa, Russia, Australia, South America, and Canada for brands like CATERPILLAR, BUCYRUS, LIEBHERR, P&H, TEREX, УЗТМ, OMZ, HITACHI, DEMAG, DOOSAN, KOMATSU, O&K, URALMASH. Choose us you will get the best quality adaptor and a reliable partner.

For related WALKSON Adapteror mining products, please feel free to contact us.

Send product request

Other supplier products

| Butterfly Valve | Walkson, as a reputable a butterfly valve company, provides butterfly valve castingand forgings for different types of high performance butterfly v... | |

| Dragline Walking Frame | WALKSONDragline walking frame or walking arm, together with walking cam and cam shaft / propel shaft are the most important parts for dragline walk... | |

| Check Valve | As a professional high pressure check valve part manufacturer, Walkson provides castings or forgings for adjustable cracking back check valves. ... | |

| Carbon Steel Forging | Carbon steel forgingwith super toughness and bending strength. The hook is made of super high carbon steel with super toughness and bending strengt... | |

| Shredder Hammer Tips/ Knife Edges | Our shredder hammer tips are bi-metallic composites having 700BHN hardness and available in various sizes and shapes. Our products are widely used... |