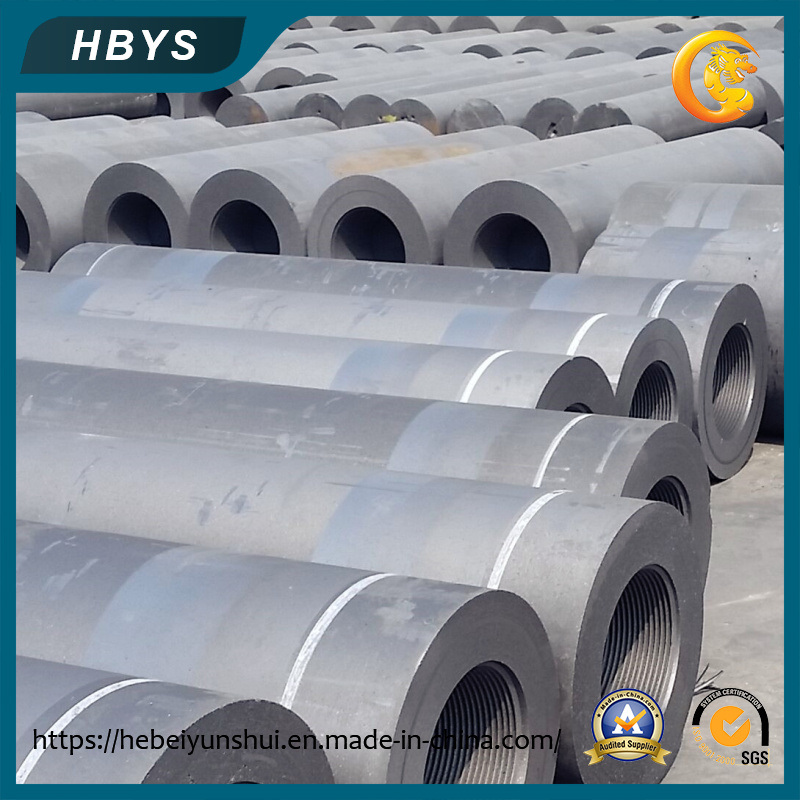

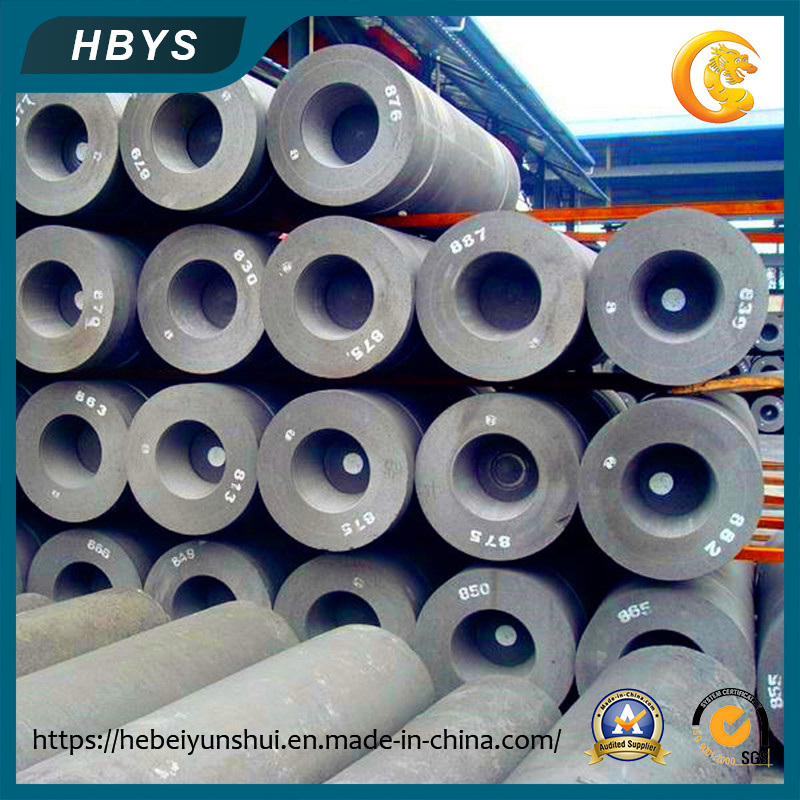

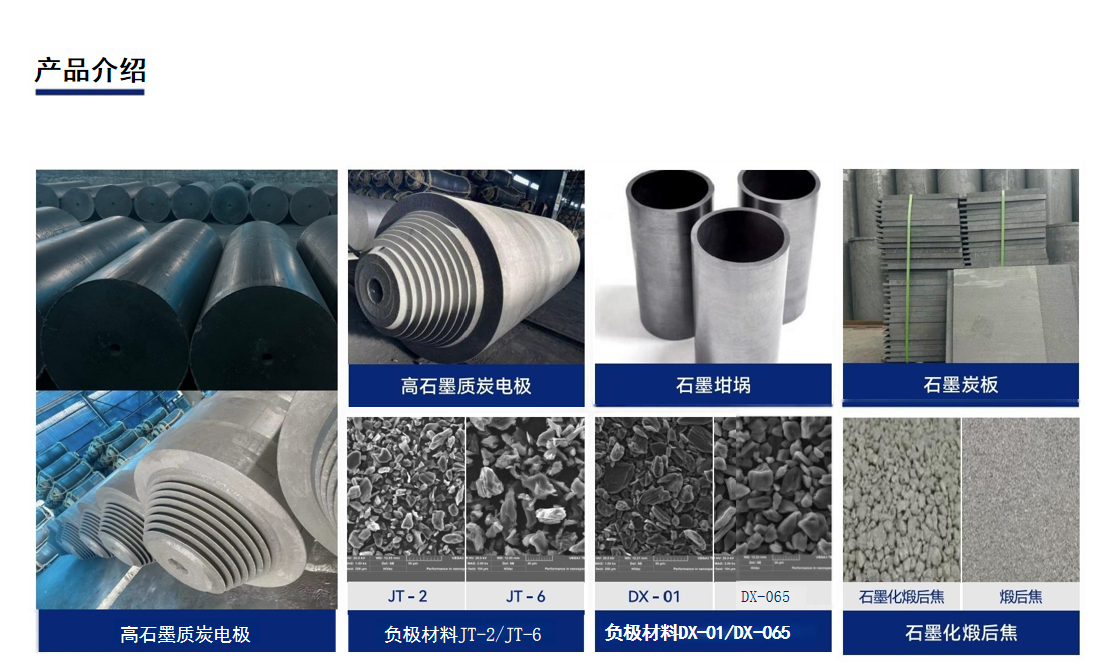

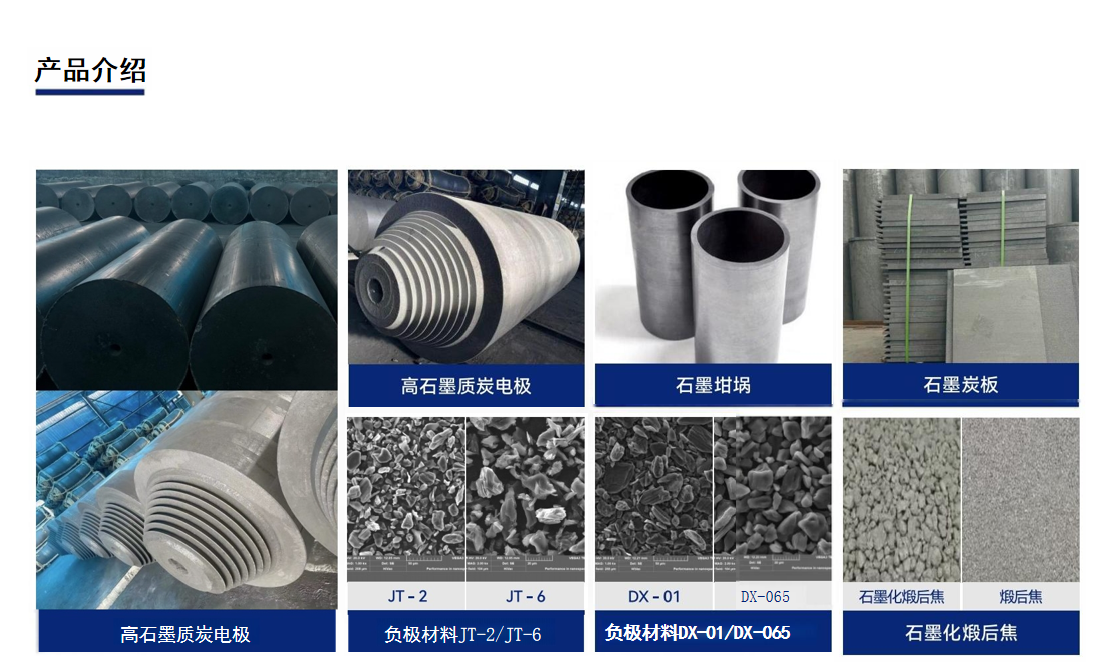

High quality graphite electrode for electric arc furnace

Graphite electrode is a kind of high temperature resistant graphite conductive material produced by a series of technological processes including petroleum coke, needle coke as aggregate, coal asphalt as binder, kneading, molding, roasting, impregnation, graphitization and mechanical processing. Graphite electrode is an important high-temperature conductive material for steelmaking in electric furnace. Through the graphite electrode, electric energy is input to the electric furnace, and the high temperature generated by the arc between the electric extreme part and the charge is used as the heat source to melt the charge for steelmaking. Graphite electrodes are also used as conductive materials in other ore furnaces for smelting materials such as yellow phosphorus, industrial silicon and abrasive. Graphite electrode has been widely used in other industries for its excellent and special physical and chemical properties.

The electric arc furnace (eaf) is a kind of steelmaking method which is produced by the electric arc between the electrode and the charge, which turns the electric energy into heat energy in arc light, and fuses the metal and slag with the direct action of the radiation and the electric arc.

Company since 2007, when the new production of the tunnel furnace, LWG graphitizing furnace, stained by immersion workshop, fully automatic CNC joint and electrode of mechanical processing equipment, is a domestic advanced automated production of the enterprise, customers in the Middle East and Japan, Brazil, and other places, the main production of high power, high power graphite electrode, the electrode is mainly used for steelmaking, also can be used in the yellow phosphorus, silicon smelting.

Physical and chemical index of graphite electrode is an important reference index of electrode quality.These include bulk density, resistivity, flexural strength, modulus of elasticity, coefficient of thermal expansion, and ash.

Physical and chemical indexes of ordinary power graphite electrode

| |

|

|

Nominal Diameter(mm) |

| |

|

|

75--200 |

250--300 |

400--500 |

| Item |

Classify |

Unit |

Superior product |

First grade |

Superior product |

First grade |

Superior product |

First grade |

| |

|

|

A |

B |

A |

B |

A |

B |

| electrical resistivity ≯ |

electrode |

μΩ.m |

8 |

9 |

8 |

9 |

8 |

9 |

| joint |

7.5 |

7.5 |

7.5 |

| breaking strength≯ |

electrode |

M Pa |

10 |

10 |

8 |

| joint |

15 |

15 |

15 |

| elasticity modulus≯ |

electrode |

GP a |

12 |

12 |

12 |

| joint |

14 |

14 |

14 |

| volume density≯ |

electrode |

g/cm3 |

1.58 |

1.58 |

1.58 |

| joint |

1.68 |

1.68 |

1.68 |

| CTE(100-600)≯ |

electrode |

X10-6/ºC |

2.7 |

2.7 |

2.7 |

| joint |

2.5 |

2.5 |

2.5 |

| Ash≯ |

|

% |

0.3 |

0.3 |

0.3 |

| Note: ash and thermal expansion coefficient are reference indexe |

Physicochemical index of high power graphite electrode

| Item |

Classify |

Unit |

Nominal Diameter(mm) |

| 200-400 |

450-500 |

550-600 |

| electrical resistivity≯ |

electrode |

μΩ.m |

7 |

7 |

7 |

| joint |

6 |

6 |

5.8 |

| breaking strength≯ |

electrode |

M Pa |

10.5 |

10 |

10 |

| joint |

14 |

14 |

16 |

| elasticity modulus≯ |

electrode |

GP a |

12 |

12 |

12 |

| joint |

16 |

16 |

16 |

| volume density≯ |

electrode |

g/cm3 |

1.62 |

1.62 |

1.62 |

| joint |

1.72 |

1.72 |

1.72 |

| CTE(100C-600C)≯ |

electrode |

X10-6/ºC |

2.4 |

2.4 |

2.4 |

| joint |

2.3 |

2.2 |

2.2 |

| Ash≯ |

|

% |

0.3 |

0.3 |

0.3 |

| Note: ash and thermal expansion coefficient are reference indexes |

Physical and chemical indexes of super high power graphite electrode

| Item |

Classify |

Unit |

Nominal Diameter(mm) |

| 300-400 |

450-500 |

550-700 |

| electrical resistivity≯ |

electrode |

μΩ.m |

6.2 |

6.2 |

6.3 |

| joint |

5 |

5 |

4.5 |

| breaking strength≯ |

electrode |

M Pa |

10.5 |

10.5 |

11 |

| joint |

18 |

18 |

20 |

| elasticity modulus≯ |

electrode |

G Pa |

14 |

14 |

14 |

| joint |

18 |

18 |

22 |

| volume density≯ |

electrode |

g/cm3 |

1.66 |

1.66 |

1.66 |

| joint |

1.75 |

1.75 |

1.75 |

| CTE(100C-600C)≯ |

electrode |

X10-6/ºC |

1.5 |

1.5 |

1.4 |

| joint |

1.4 |

1.4 |

1.2 |

| Ash≯ |

|

% |

0.3 |

0.3 |

0.3 |

| Note: ash and thermal expansion coefficient are reference indexes |

Graphite electrode recommended current load

| Nominal |

current carrying capacity(A) |

| diameter |

RP |

Dipping |

HP |

HP |

UHP |

| |

graphite electrode |

graphite electrode |

graphite electrode |

graphite electrode- |

graphite electrode |

| 75 |

1000-1400 |

1300-2000 |

|

|

|

| 100 |

1500-2400 |

1800-3000 |

|

|

|

| 130 |

2200-3400 |

2800-4200 |

|

|

|

| 150 |

3000-4500 |

4000-5000 |

5500-9000 |

|

|

| 200 |

5000-6900 |

4800-9000 |

8000-13000 |

|

|

| 250 |

7000-10000 |

8000-12000 |

|

|

|

| 300 |

|

|

|

|

|

| 350 |

|

|

|

|

|

| 400 |

|

|

|

|

|

| 450 |

|

|

|

|

|

| 500 |

|

|

|

|

|

| 550 |

|

|

|

|

|

| 600 |

|

|

|

|

|

| 700 |

|

|

|

|

|

| 780 |

|

|

|

|

|

| 800 |

|

|

|

|

|

| 850 |

|

|

|

|

|

| 900 |

|

|

|

|

|

| 1100 |

|

|

|

|

|

| 1200 |

|

|

|

|

|

Note: the current load is reduced by %10 when used in an electric arc furnace, and can be increased by %10 when used in a refining furnace.

Our mode of transportation and delivery date

The production cycle of graphite electrode is long and the process is complicated. Only good raw materials, good equipment and good technical workers can produce good products. We are located in handan, hebei, with convenient transportation.The customized graphite electrode is produced according to the size of the order, and can be delivered within a month. If you have quality problems during the use, please contact us, we will reply as soon as possible and actively seek solutions to minimize your loss.

We mainly deal on FOB and CIF basis.

If you have any questions about the graphite electrode, please feel free to contact us with an enquiry.We will provide you with the most comprehensive service.

Other supplier products

All supplier products

Same products