The Development Course of SG Grinding Wheel

The Development Course of SG Grinding Wheel

Production methodsof SG abrasive

SG abrasives are made by sintering special crystalline gel system, with revolutionary new generation of alumina abrasives, with high hardness, good toughness and high sharpness.

Compared with ordinary corundum abrasive, SG has advantages of high abrasion ratio, good shape retention, good workpiece surface processing quality, small amount of grinding wheel dressing and high grinding efficiency.

What’s the application of SG grinding wheel?

SG grinding wheel is especially suitable for grinding aerospace alloy, tool steel, hardened workpiece, hard chromium, hard cast iron, etc.

Due to the high price of SG abrasive, SG can be mixed with white corundum (or other corundum abrasive) in a certain proportion according to the grinding requirements of different occasions to make the grinding wheel, so as to achieve the best combination of grinding effect and grinding wheel cost.

The grain size of abrasive is used to indicate the size of abrasive particles.

The selection is mainly based on the surface roughness required to process the workpiece, and other factors (such as grinding efficiency, village material characteristics, etc.) should also be considered.

For example, the common particle size has the following relations with the surface roughness:

54 to 60;70-80;90-100;Roughness of 1.6;0.8.0.4;0.2 l;

Coarse-grained abrasive is suitable for grinding: soft material, high elongation and materials such as soft iron and nonferrous metals.

Where the surface roughness is not high, the grinding efficiency is high and the feed quantity is high.

Grinding large contact surfaces.

Fine grained abrasive is suitable for grinding: high hardness and brittle materials such as high carbon tool steel, hard alloy and glass.

High surface roughness and precision requirements.

Grinding a small contact surface.

Small workpiece radius or solidity.

The hardness of the grinding wheel refers to the degree of bonding between abrasive materials. The degree of binding dose in the grinding wheel determines the hardness of the grinding wheel.

The user needs to choose the hardness of the grinding wheel flexibly according to the specific grinding requirements (such as feed amount, roughness and material).

The general principle of grinding wheel hardness selection:

The general principle of grinding wheel hardness selection issoft hardness, rough grinding with a large amount of feed toolsgrinding of hard workpieces with large contact surface, such as high hardness tool steel and hard alloy, etc.,

which have poor thermal resistance, strictly prevent hard surface burns

1)fine grinding with small amount of feed knife

2) extend the life of the grinding wheel;

3) grinding of workpiece material softer contact area small or narrow places Group number to said the distance between the adjacent abrasive grain in the grinding wheel, which is the size of the grinding wheel clearance volume percent of the abrasive particles, its concentration, the size of the decision of grinding wheel group, ceramic grinding wheel group number range from 5 to 13, the smaller the number said grinding wheel organization closer, the larger the number said grinding wheel organization the osteoporosis Organization no. 11, 12 and 13, often referred to as air hole grinding wheel bond:

Binding agent is one of the key components of grinding wheel. Its function is to bind abrasive particles together to form grinding wheel, so as to help it realize grinding function

1. SG abrasive came out

In 1981, the industrial abrasive department of 3M introduced a ceramic corundum abrasive material entitled "Cubitron".

Its toughness is more than twice that of the common fused alumina.

The grinding performance is superior to that of most common abrasive materials.

In the mid-1980s, NORTON developed SG, a ceramic corundum grinding material with similar properties to Cubitron abrasives, both of which were made using a chemical ceramic process known as sol-gel (SG).

SG abrasive is also named because of this, and its process is: preparation of A13O2·H2O water sol, after gelation.

The SG process is often called "Seeded ge1" due to the use of primers (or seeds) in the sol-gel process.

SG as a technology did not appear in the 1980s.

In 1963, Bugosh obtained the patent for manufacturing dense Al2O3 with SG process, and the manufacture of oxide ceramics with sol - gel (SG) process was also common in the ceramic industry, but SG process was not used for abrasive production until the 1980s.

SG abrasive tools are also being used in industrial processing.

In addition to 3M and NORTON in the United States, there are other companies producing abrasive with SG process. Therefore, SG abrasive in this paper refers to corundum abrasive produced by sol gel (SG) process, not only NORTON products.

2. Manufacturing process of SG abrasive

In a general sense, SG abrasive manufacturing process is to first mix aluminum monohydrate (Al2O3·H2O) powder and water into a suspension, in which a colloidal solvent (such as nitric acid or hydrochloric acid solution) is added to make it a stable aqueous sol or colloidal suspension.

Then, a modified agent (usually a metal oxide or its predecessor, such as Mg (NO3) 2, etc.) is added to gelate the sol.

The formed condensate will be dried and solidified, and then broken (or cut) into the required shape and size of particles, which will be turned into abrasive after calcination.

The specific manufacturing process is as follows:

(1) production of A12O3·H2O water sol:

This process is mainly to mix monohydrate alumina powder and water evenly into suspension.

In order to maintain the stability of suspension, appropriate amount of colloidal solvents (such as nitric acid or hydrochloric acid solution) should be added to make it into a stable aqueous sol or colloidal suspension.

The material used to make suspension can be Al2O3·H2O powder or pure A12O3 powder.

Generally, the content of Al2O3·H2O should be 15-30% in the water sol produced. The solvent used in this process is a volatile unitary acid, such as nitric acid, hydrochloric acid, acetic acid, etc., but the effect of nitric acid is the best.

Generally speaking, the amount of acid should be appropriate, and the PH value of the hydrosol formed after adding acid is l~2.

Excessive amount will make the addition of the improved agent, the gelation speed is too strong, it is difficult to mix evenly, affecting the quality of abrasive.

(2) gelation process:

The modified A12O3·H2O water sol was added to promote its gelation.

The modifier is usually a metal oxide, such as MgO, ZnO, ZrO2, TiO2, etc. The most commonly used one is MgO.

Mg (NO3) 2 will decompose into MgO in the subsequent drying, calcination and sintering process, so its effect is the same as that of MgO.

Another commonly used improver is ZrO2, which is added in the form of a solution of zirconia acetate, which is decomposed into ZrO2 in a later process.

The H2O water sol is mixed with the aqueous solution of the precursor of the improver (Mg (NO3) 2 or zirconium acetate or other) and stirred, and the gel is immediately produced.

(3) dry curing:

Dry and solidify the raw gel.

Temperature is in commonly 80 ~ 120 ℃, should pay attention not to make the temperature higher than the temperature at which the gel foaming, eventually burn free of abrasive high porosity, lower hardness.

By removing 90% of the free water in the gel during the drying process, the gel becomes a glassy lump after drying. Although it looks dense, it is very fragile, and the fingers will break when pressed.

(4) pre-crushing:

In order to sintered abrasive of a certain shape and size, it is necessary to break the dry lump solid into particles of a certain size before calcination and sintering, or to use cutting, extrusion molding and other methods to make the desired shape and size.

Broken screen after sorting out useful to burn into abrasive particles, for the next working procedure, because the particles volume tends to shrink in the sintering process of 20 ~ 40%, thus broken out particles should be slightly bigger than a finished product required by the abrasive grain size, screening out too big particles should be broken again, too small particles can be made into hydrosol body again.

(5) calcination:

After the broken particle heating to 600 ~ 800 ℃ calcination, should slowly heat up, ensure that the generated volatile substances volatile out fully, at the same time will not make particles generated inside high internal stress.

When heating to 250 ~ 300 ℃, acid residue left by the sol-gel process is basically all evaporate, during 300 ~ 600 ℃, combined water in the most also evaporate.

At the same time, the precursors (Mg (NO3) 2 or zirconium oxide-based acetate, etc. are also decomposed to form metal oxide modifiers MgO and ZrO2, etc.).

(6) sintering into abrasive:

After calcining heat quickly make particle temperature is above 1200 ℃, and then heating for a period of time, to keep temperature at 1300 ~ l400 ℃, prompting burn as abrasive particles.

Rapid heating process and heat preservation sintering process are actually two closely connected processes.

Rapid heating process is best in 1 minutes, the temperature at which the particles from calcining temperature (800 ℃) or less on the rapidly rising to 1200 ℃.

Industry is generally after calcining particles in the preheat to 1300 ℃ high temperature furnace, to achieve the goal of rapid heating.

Rose from 800 ℃ to 800 ℃ the time directly affects the performance of the sintered abrasive Is in commonly 1300 ℃ heat preservation sintering temperature, the time required for 5 ~ 30 minutes.

However, it is not advisable to keep sintering at high temperature for a long time, because it tends to cause the quench-a12o3 crystal to grow too large and reduce the hardness and toughness of abrasive materials.

In the process of sintering, the improver (MgO, ZrO2, etc.) not only reduces the temperature required for sintering, but also promotes the transformation from other forms of A12O3 (such as -a12o3) to -a12o3, and inhibits the excessive growth of -a12o3 crystals, so that the abrasive formed by burning is mainly composed of -a12o3 substrates and microcrystals.

3. Improvement of SG abrasive process: use of crystal primer

In SG process, the post -A12O3 or post -Fe2O3 microcrystals were added to the sol or gel, which could make the interior of the gel more compact.

During sintering, these added regular-a12o3 or regular-fe2o3 microcrystals, as primer components (or seed species), promote the brush circumference formation of the granular-a12o3 microcrystals in order to speed up the sintering process. The internal structure of the sintered abrasive is denser and the properties of the abrasive materials are also improved, which is called the crystal priming.

Action needed for led crystal agent can reduce the sintering temperature, according to some patents, sinter with alpha A12O3 microcrystalline seed, A12O3 gels (dry broken) in 1090 ℃ into alpha A12O3 crystal.

If no alpha A12O3 microcrystalline seed, the shift under 1190 ℃.

The method of adding the primer can directly add the gray-a12o3 or q-fe2o3 micropowder to the prepared sols or gels, or the gels can be ground in a ball mill using the hunter-a12o3 as the grinding medium, and the -a12o3 microparticles can be ground into the gels after being ground into powder.

The particle size of q -A12O3 or q -Fe2O3 primers was 30~70nm.

4. Physical and chemical properties of SG abrasive

SG abrasive has excellent toughness, which is twice as strong as that of normal corundum, and its hardness is similar to that of normal corundum.

In fact, it does not have an accurate toughness or hardness number due to its different chemical composition and small differences in the manufacturing process.

In addition, since SG abrasive particles are made by sintering a large number of sub-micron A12O3 crystals, they can break continuously and expose new cutting during grinding, so their self-sharpening performance is particularly good.

Its grinding performance is obviously better than that of corundum, which is characterized by wear-resisting, self-sharpening, high removal rate and large grinding ratio.

Currently, only saint-gobain, 3M, tebak, VSM, Hermes and others are available in the world.

The American 3M company is called "Cubitron". Its crystallization is within the maximum allowm.

The company is called SG abrasive, and its crystal shape is Norton weigen m.

Hermes, a German company called CB abrasive, has a maximum crystallization of 5 oxidation m.

A kind of CX abrasive in Japan whose crystal model is called 1.

Domestic four sand taiyi, the mountain big east heng and other enterprises are also in production.

Seeded Gel (SG) abrasive from NORTON is a patented product of the company's Ceramic Aluminum Oxide for high efficiency grinding of refractory materials.

It contains thousands of tiny crystals in each abrasive grain produced by a process.

The microscopic structure of each ceramic abrasive grain enables it to self-sharpen and continuously expose new, sharp cutting edges.

The manufacturing process of SG abrasive is completely different from that of ordinary alumina abrasive. It starts from submicron particles, removes impurities and sinteres them to produce abrasive particles. Therefore, SG abrasive material is very dense, rough, strong and sharp.

SG abrasive wear produces a sharp cutting edge similar to the tool back Angle, so SG abrasive cutting temperature is lower, it has less burn or metallographic damage to difficult grinding materials than ordinary aluminum oxide, and can keep sharp for a long time under low load, less total stop time and longer life.

As a result, SG abrasive belts and sand plates can be quickly cut on hard grinding materials such as aerospace alloys and forged steel.

SG abrasive's unique ability increases production and lowers labor costs.

5. SG grinding products

SG abrasive can be used to make all kinds of consolidation and coating grinding tools, and their performance is obviously better than that of similar common corundum grinding machines. Generally speaking, SG abrasive materials have a high manufacturing cost, so it is commonly used in industry to make grinding machines mixed with common abrasive materials.

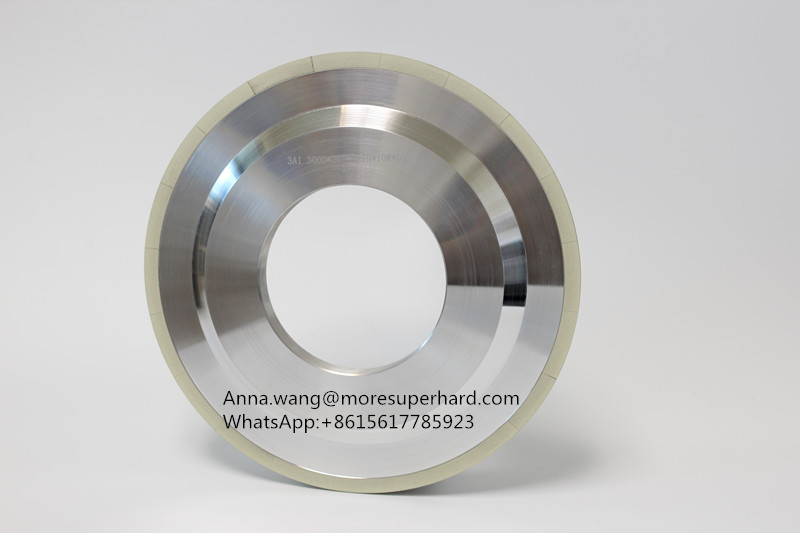

(1) SG abrasive grinding wheel

NORTON, the main producer of SG grinding wheels, began producing them in its factories in the United States, Japan, France and elsewhere in the late 1980s and has been selling them around the world.

Due to the superior performance of this kind of grinding wheel, it has received great attention, and more and more people begin to use this kind of grinding wheel in aviation, automobile, cutting tool, mould and bearing industries and so on and have been favored.

The SG grinding wheel of NORTON is usually made by mixing SG abrasive with the company's 38A abrasive. There are four types of SG abrasive: 100%, 50%, 30% and 10%. The grinding wheel is also named SG, 5SG, 3SG and 1SG grinding wheel respectively.

The binding agent used is usually ceramic binding agent, but there are also resin binding agent.

Besides 38A abrasive, SG abrasive can also be mixed with brown fused alumina, zirconium fused alumina, silicon carbide, or even CBN and diamond to make grinding wheels.

(2) SG/CBN grinding wheel

All made of SG abrasive grinding wheel, the most striking is NORTON SG/CBN grinding wheel (registered trademark CVSG) as it is to use a new type of ceramic bond and SG abrasive and CBN abrasive mixing of sintering, SG abrasive toughness, since the sharpness and CBN advantages of super hard, wear-resistant, long life, in addition to the high rate, high processing precision grinding, especially suitable for aerospace, automotive, knives and other industrial precision grinding processing.

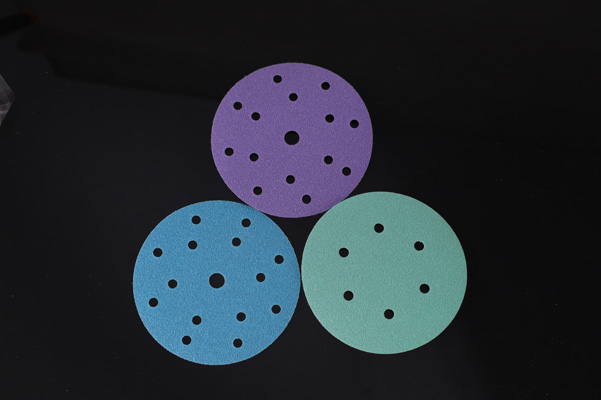

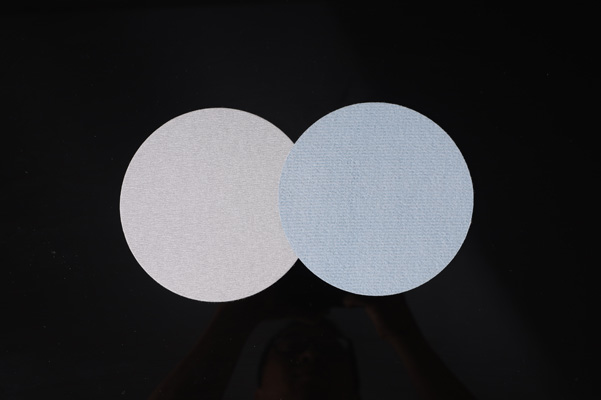

(3) SG abrasives are coated with abrasive tools

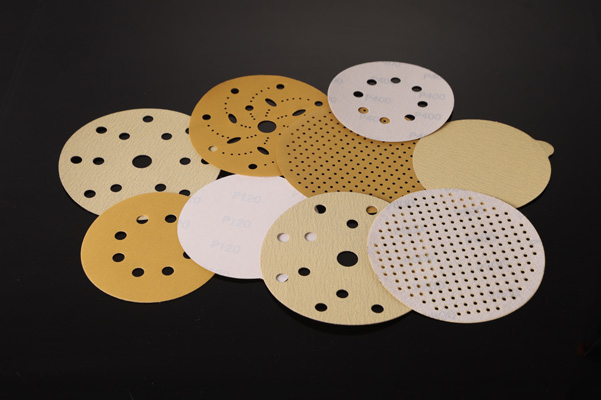

The coated abrasives made of SG abrasive include sand belt, sand disc, sand cloth, advanced non-woven abrasive belt, mainly sand belt.

3M USES its Cubitron abrasive to make sand belts, with Multicut as its registered trademark. After grinding tests, its performance is significantly better than that of ordinary corundum sand belts. NORTON also produces such sand belts with the registered trademark Vulcan SG.

6 the development prospects of SG abrasive

SG abrasive is a new kind of ceramic corundum abrasives, its emergence has artificial abrasive to the high toughness and high hardness of the trend of the development of the two directions, however, the importance of SG abrasive dry grinding processing field, is not limited to it as a kind of new ceramic materials will have very broad application prospects at present, our country's alumina manufacturing most of the adopted is one of the traditional electric smelting process, sintering process manufacturing corundum abrasives, rarely also SG abrasive is still the gap in our country

The ceramic corundum abrasive belt shows superior grinding performance in strong grinding, which is mainly formed in the process of sol-gel synthesis (i.e., sol-gel process) and low-temperature sintering and molding. Compared with the common corundum abrasive belt, it shows great difference from the crushing resistance of the grinding grain microstructure to the abrasion mechanism

Send product request

Other supplier products

| glass edge polishing grinding wheel | Glass Polishing Wheel glass edge polishing grinding wheel glass cotton polishing wheel 6 50mm glass polish machine gimi 9 diamond wheel price g... | |

| Vitrified bond diamond wheel suppliers | vitrified diamond grinding wheels Detail: Our vitrified diamond grinding wheels for PCBN and PCD toolshave been produced in-house for many years.W... | |

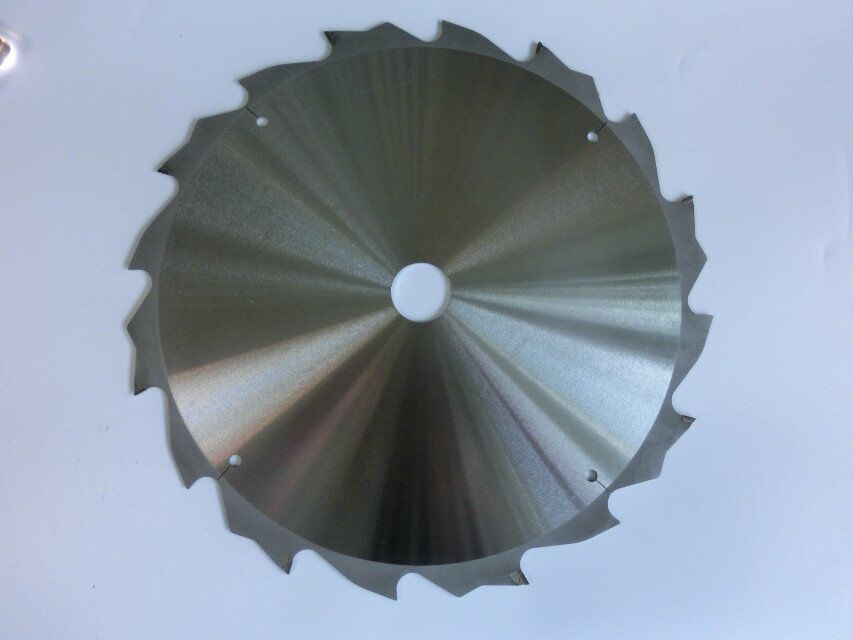

| Diamond wheels for PCD circle saws | diamond and CBN grinding wheels for woodworking industry are mainly used for top, face and side grinding the circular saw blades and band saws ma... | |

| PCD saw Blade for cutting fiber cement boards | PCD saw Blade for cutting fiber cement boards AdvangtagesInternal stress removed, deformation will not happen after long time usingHigh bend... | |

| CVD single crystal plates Optical grade CVD flake shape | CVDdiamondisdiamondproducedinanartificialprocess,asopposedtonaturaldiamonds,whicharecreatedbygeologicalprocesses.CVD diamond is used for ultra prec... |

Same products

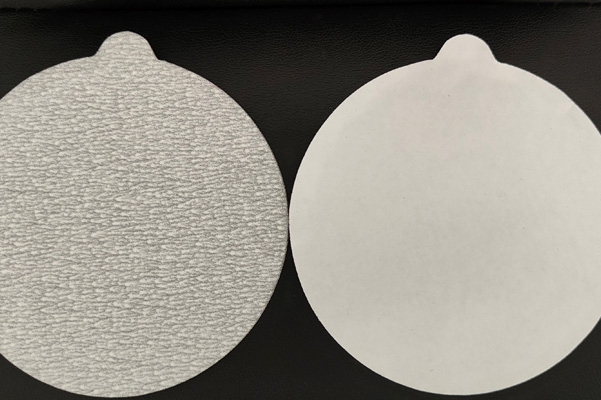

| AF38M Blue Abrasive Film | Seller: CHANGZHOU RMN ABRASIVES CO., LTD | RMC AF38M blue abrasive film can be used as Velcro and PSA disc, and also suitable for different ... | |

| AP36M Velcro Disc | Seller: CHANGZHOU RMN ABRASIVES CO., LTD | RMC AP36M abrasive velcro sandpaper discsimpregnated latex, flexible. Special super stearated coa... | |

| AP36M PSA Sanding Discs | Seller: CHANGZHOU RMN ABRASIVES CO., LTD | RMC AP36M abrasive paper PSA sanding discimpregnated latex, flexible. Special super stearated coa... | |

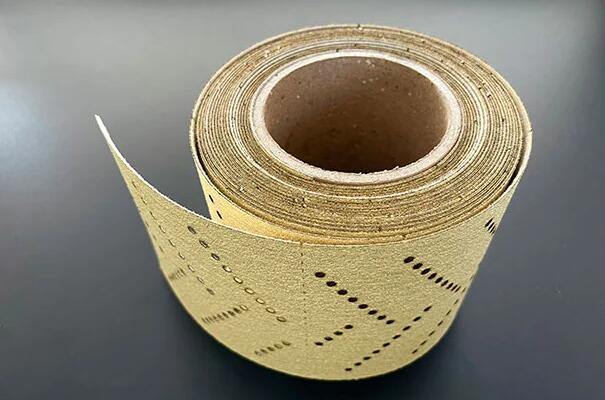

| AP33M Velcro Backed Sandpaper | Seller: CHANGZHOU RMN ABRASIVES CO., LTD | RMC AP33M velcro sanding paperroll is a special sandpaper product suitable for fast sanding. Prem... | |

| AP33M PSA Sanding Discs | Seller: CHANGZHOU RMN ABRASIVES CO., LTD | RMC AP33M PSA sanding discis a special sand paper product suitable for fast sanding. Premium alum... |