B4C powder F230 F240 95% boron carbide raw material

B4C powder F230 F240 95% boron carbide raw material

neutron shielding additive B4C boron carbide powder,also known as B4C is produced from high temperature smelting boric acid and carbon materials in electric furnaces. Boron carbide is with high hardness up to Mohs’ 9.3, which is the third hard material besides Diamond and CBN.

Properties:

- High temperature resistance, acid-alkali resistance

- Boron carbide can get bigger Neutron interception area with high Neutron absorb ability.

- High strength, high chemical stability

- Low specific gravity

|

TYPICAL PHYSICAL PROPERTIES |

|

|

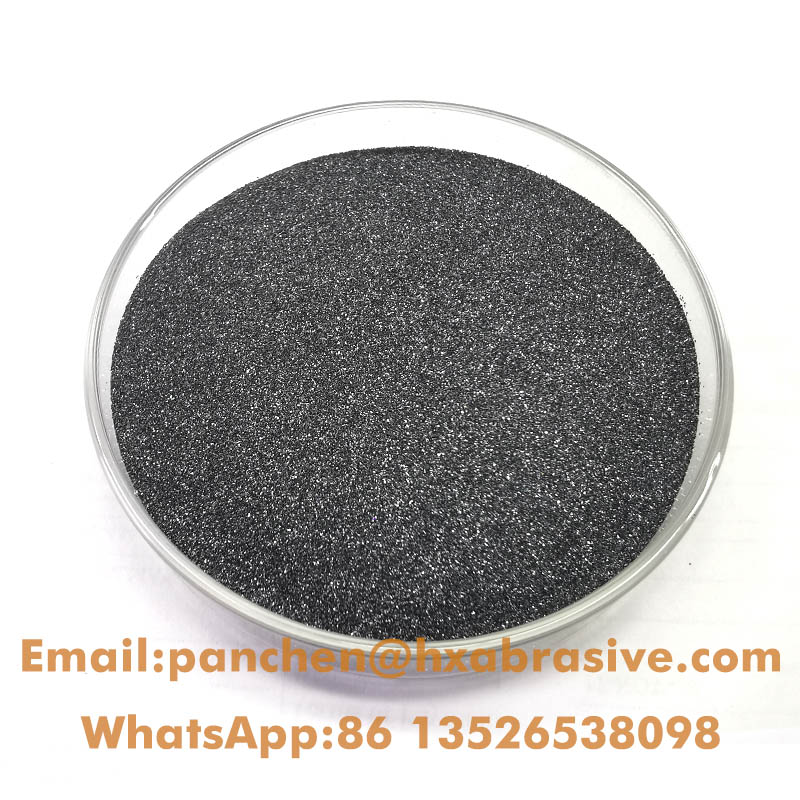

Appearance |

Black powder |

|

Molecular Weight(g/mol.) |

|

|

Specific Heat(cal-mol-c) |

|

|

Knoop hardness |

2750 |

|

Mohs hardness |

|

|

Micro Hardness |

4950kgf/mm2 |

|

Bending strength |

Min 400Mpa |

|

Density&phase |

|

|

Melting point |

2450℃(2623.15K) |

|

Boiling point |

>3500℃(>3773.15K) |

|

Solubility in water |

Insoluble |

|

Crystal structure |

Rhombohedral |

Available sizes:

F-macrogrit F40 F46 F54 F60 F70 F80 F90 F100 F120 F150 F180 F220

F-microgrit F230 F240 F280 F320 F360 F400 F500 F600 F800 F1000 F1200 F1500

Fine powder:-100#,-200#,-325#,60-150#,25um-0,10um-0,3um-0

|

size |

grit |

mean diameter in um |

B % |

C % |

Fe2O3 % |

B4C% |

|

F-macrogrit |

F40 |

425 |

76-80 |

17-21.5 |

95-99 |

|

|

F46 |

355 |

|||||

|

F54 |

300 |

|||||

|

F60 |

250 |

|||||

|

F70 |

212 |

|||||

|

F80 |

180 |

|||||

|

F90 |

150 |

|||||

|

F100 |

125 |

|||||

|

F120 |

106 |

|||||

|

F150 |

75 |

|||||

|

F180 |

75-63 |

|||||

|

F220 |

63-53 |

|||||

|

F-microgrit |

F230 |

D50=53 |

75-79 |

95-97 |

||

|

F240 |

D50=44.5 |

|||||

|

F280 |

D50=36.5 |

|||||

|

F320 |

D50=29.5 |

|||||

|

F360 |

D50=22.8 |

|||||

|

F400 |

D50=17.3 |

|||||

|

F500 |

D50=12.8 |

|||||

|

F600 |

D50=9.3 |

74-79 |

93-97 |

|||

|

F800 |

D50=6.5 |

|||||

|

F1000 |

D50=4.5 |

|||||

|

F1200 |

D50=3.0 |

|||||

|

F1500 |

D50=2.0 |

|||||

|

Fine powder |

100#-0 |

150max |

75-80 |

17-21 |

||

|

200#-0 |

90max |

|||||

|

325#-0 |

45max |

|||||

|

60#-150# |

250-75 |

|||||

|

25um-0 |

25max |

|||||

|

10um-0 |

10max |

|||||

|

3um-0 |

3max |

Applications:

Send product request

Other supplier products

| Abrasive grain Green silicon carbide 64C F60 F80 | Green silicon carbide grit Green silicon carbide grit is a very hard abrasive material . The hardness of itonly ranks after diamond and B4C, and it... | |

| High quality boron carbide extra fine powder F1000 F1200 | High quality boron carbide extra fine powder F1000 F1200 neutron shielding additive B4C boron carbide powder,also known as B4C is produced from hi... | |

| Metallurgical Silicon carbide black 1-2mm 1-3mm | Metallurgical Silicon carbide black 1-2mm 1-3mm Product Introduction Black silicon carbide (SiC) is also called black carborundum. It is a non-me... | |

| Ceramic shot blasting media B60 B80 | Ceramic shot blasting media B60 B80 The main component of ceramic shot is zirconia, which is mainly used for surface treatment such as sand blas... | |

| Silicon carbide F054 F060 A grade 98% purity | Black Silicon carbide Grain is an extremely hard and 99% SiC carborundum grit. As an abrasive material, it can work well for abrasive blasting, sur... |

Same products

| Dresser, 0.4 Carat Single Point Grinding Wheel Tapered Point Tool for Dressing and Grinding Bench, Item surface, Cylindrical Internal Grinding | Seller: 青岛晟鑫杰金刚石工具有限公司 | ||

| Aluminum Oxide Fiber Disc | Seller: CHANGZHOU RMN ABRASIVES CO., LTD | Aluminum Oxide Fiber Disc It is strong and has durable, long sanding life, high sanding performa... | |

| AJ26M Abrasive Belts for Metal | Seller: CHANGZHOU RMN ABRASIVES CO., LTD | AJ26M Abrasive Belts for Metal RMC AJ26M abrasive belts for metal backing is Jwt flexible and hi... | |

| AJ25 Aluminium Oxide Abrasive Belts | Seller: CHANGZHOU RMN ABRASIVES CO., LTD | AJ25 Aluminium Oxide Abrasive Belts The backing cloth make anti-slip treatment with high strengt... | |

| AF37M Green Abrasive Film | Seller: CHANGZHOU RMN ABRASIVES CO., LTD | RMC AF37M green abrasive microfinishing filmcan be used as Velcro and PSA disc, and also suitable... |