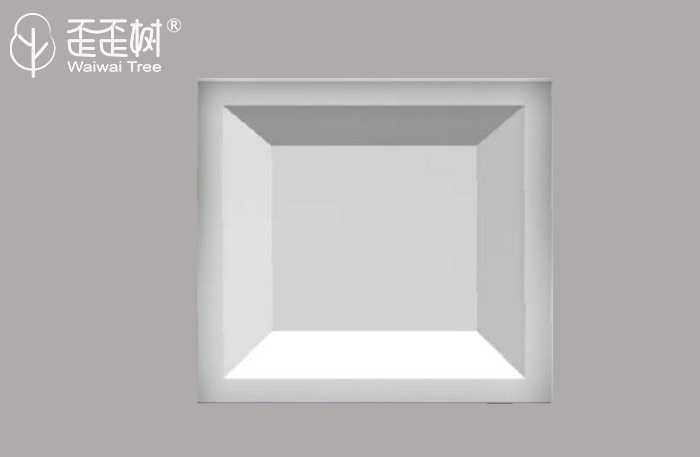

BMC, SMC, GRP, GFK Ceiling

Aobang composite ceiling is divided into: BMC ceiling, SMC ceiling, GRP ceiling, GFK Ceiling.

The ceiling materials have been developed for more than ten years, and the technology is constantly being updated. The PVC ceiling is not resistant to high temperature, and it is easy to deform in a hot environment. The plastic steel plate is improved from the second generation of ceiling material PVC, which has the advantages of lower price, good thermal insulation and sound insulation, rich color and easy making and installation.

However, according to the supervision and inspection results of the plastic sheet market by the Supervisory Office, the quality pass rate of plastic steel products on the market is only 40%, and the phenomenon of “water injection” in bending strength, coating thickness and alkali resistance is serious. Moreover, the plastic steel sheet has low strength, is easily twisted, is not environmentally friendly, has poor weather resistance, and releases toxic gases when burned. The physical properties of the composite material aggregate ceiling are very stable, and will not be deformed even if the water is long time.

The composite ceiling is an excellent material for the ceiling and naturalization board in terms of strength and rigidity. The ceiling uses BMC,SMC,GRP,GFK bulk molding compound as a completely environmentally friendly material, and its advantages are numerous, as follows:

Beautiful, moisture-proof, easy to clean, excellent flame retardant effect, high strength, long life, high environmental protection, easy installation, moisture-proof and waterproof, heat insulation, corrosion resistance, tight connection, oxidation resistance, anti-aging, no deformation, high strength, Light and tough, with natural texture and wooden texture, a variety of colors, natural and beautiful, with a variety of specifications, size, shape, thickness, the same processing properties as logs, no pollution, recycling, no cracks, no expansion, no deformation, no maintenance, no mold, anti-corrosion, anti-insect, anti-termite, energy saving. What is important is the low material cost of BMC,SMC,GRP,GFK molding compound, making it a cost-effective ceiling material than such as steel-plastic panels, aluminum gussets, and aluminum alloys.

The visual effect is soft, feels good, high strength, flame retardant, fireproof, and has strong weather resistance.

Excellent insulation and heat insulation performance, which overcomes the poor thermal insulation performance of traditional ceilings.

Good water resistance, no corrosion, no deformation, no fading and no other undesirable phenomena in a humid environment.

Excellent sound absorption, it is a good sound insulation material, suitable for public places such as medium and high-grade office buildings and large conference halls.

Established in 2010 and located in Chengnan Development Zone, Luoshe Town, Huzhou City, Zhejiang Province, Zhejiang Aobang Technology Co., Ltd. has extensive bulk molding compound processand many refined testing laboratories as a spinal column in the industry. Whether at home or abroad, Zhejiang Aobang Technology Co., Ltd. can manufacture top quality composite molds with advanced mold making concept, proprietary application technology and production technology. By the way, being a high-tech enterprise, it is a fact that this company enjoys a good fame in the new motor and energy automobile industry in Hangzhou.

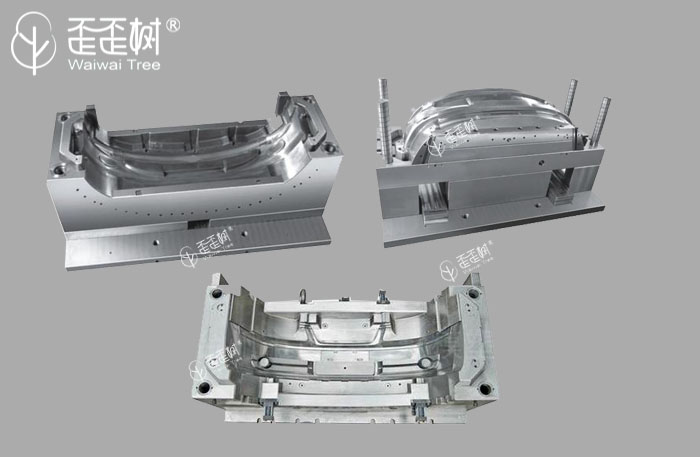

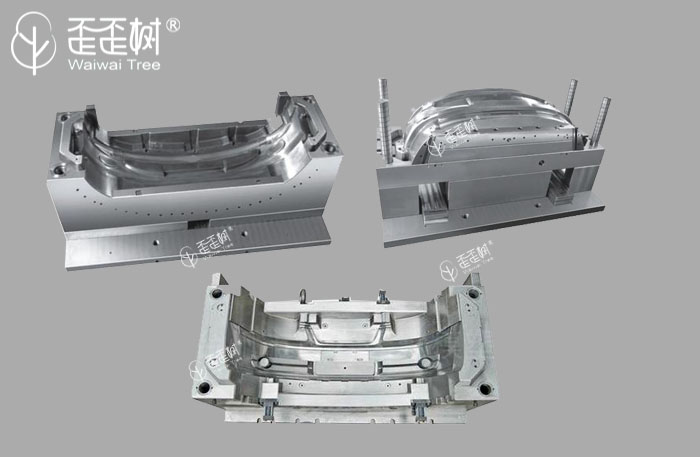

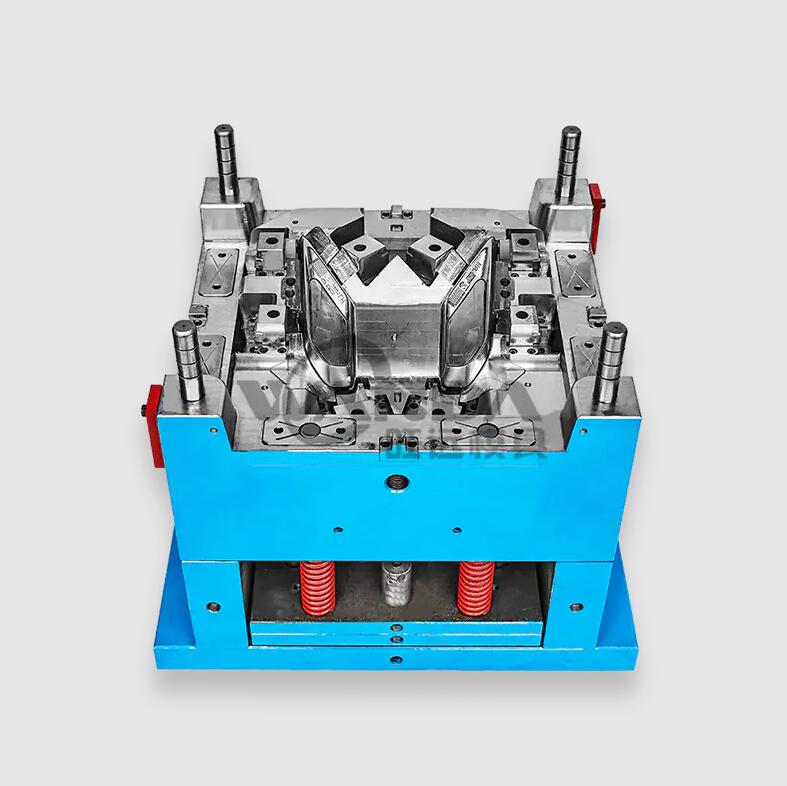

SMC and BMC compositerequire heating rather than cooling systems. The temperature of the mold is usually between 130 and 160. It is very important to keep the temperature of the mold and the exhaust gas when designing the mold. The mold is easier to fill, the product is not easy to be deformed, and the surface is better. Commonly used heating systems are steam, oil and electric heating rods.

Vacuum assisted systems for BMC and SMC molds: Products with Class A surfaces are usually vacuum-assisted, and the internal cavity and vacuum insulation of the mold are very important. The mold must have a sensor and a vacuum system to measure the mold temperature and pressure vacuum. Production SMC and BMC molds must guarantee high quality, long life and economy. Aobang Technology Co., Ltd.'s years of experience in the production of SMC and BMC molds and proficiency in machine, mold, material and process can ensure the maximum benefit of customers.

Send product request

Other supplier products

| Auto Parts Mould | BMC Auto PartsMould Automobiles are different in size and shape. That means automobile suppliers always need flexible auto parts molds, once there... | |

| Low-Voltage Electrical Products | Low Voltage Electrical Appliance Mould Manufacturer Mainly refers to circuit breakers, fuses, switch boxes, transformers, electric control boxes, ... | |

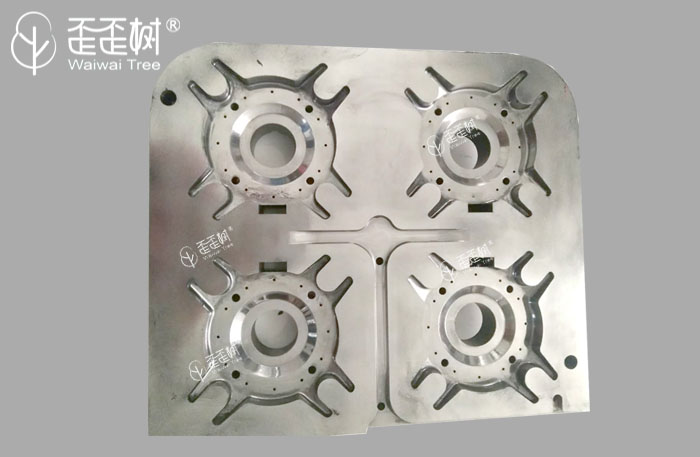

| SMC Cable Braket | The BMCcompositeprecision molds produced by Waiwai Tree have the characteristics of low energy consumption; our SMC and BMC moldinghave no waste, a... | |

| BMC/SMC Mould | BMC/SMC plasticMoulding Description: We mainly use injection molding and pressure molding as the methods. When designing the flow channel and part... | |

| Auto Parts Mould | Auto Parts Mould Features Injection molding and pressure molding are the main methods. When designing the flow channel and parting surface, the... |

Same products

| Precision And Durable Multi-Specification Automobile Buckle Mold | Seller: Yueqing Huangrong Mold Co., Ltd. | Automotive door panel clip frame molds are essential tools in this process, ensuring that the cli... | |

| Custom Motor Mold | Seller: 846123 | 90 Three-row High-Speed Progressive Stamping Mould Custom MotorMold () The 90 Three-row High... | |

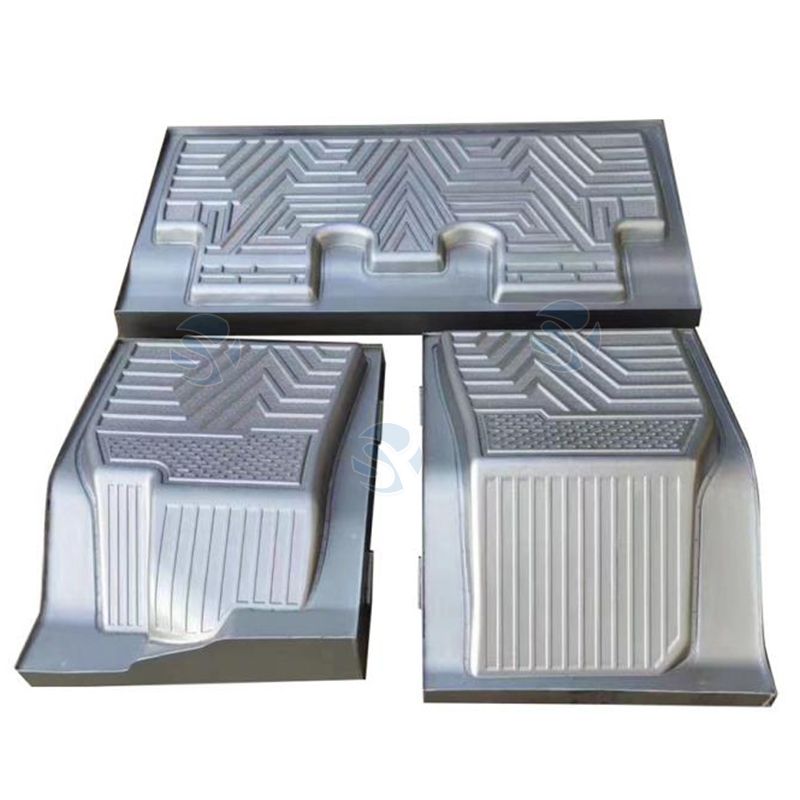

| Car Mat Aluminium Vacuum Mould | Seller: Hebei Shuiyuan Trading Co., Ltd | Product Description Vacuum molding is the most popular technology for shaping plastic raw mate... | |

| Auto Mould-Safe and Convenient Operation | Seller: Taizhou Wanda Plastic Mould Co.,Ltd. | Product Name Auto Parts Mould Brand Wanda Mould Model No specific Model Material S136/H1... | |

| SMC Cable Braket | Seller: ZHEJIANG AOBANG TECHNOLOGY CO.,LTD | The SMC cablebracket is a combination consisting of a cable bracket, a post and a fixed pin. The ... |