SMC Cable Braket

The SMC cablebracket is a combination consisting of a cable bracket, a post and a fixed pin. The material of the column and the pin is also made by the high temperature pultrusion of the FRP composite. The column can be arbitrarily cut length according to the needs, the height of the layer is adjusted, and the assembly is free. The cable bracket has various specifications to meet different lengths and load requirements.

Light weight, high strength, aging resistance, UV protection, more importantly, 1 mm can withstand voltages above 10,000 volts, it is a good insulation material.

Features: high insulation, chemical resistance, high fire resistance, good water resistance, accurate size, stable working performance, light weight, high strength, acid and alkali resistance, waterproof, moisture-proof.

SMC Cable Braket Specification

|

Project |

SMC Cable Braket |

Galvanized angle bracket |

|

Density (g/cm3) |

||

|

Specific strength |

167 |

90 |

|

Corrosion resistance (80°/100h) |

||

|

Insulation strength (kv/mm) |

Conductive |

|

|

Flame retardancy |

meets the FH-1 |

-- |

|

Water resistance (%) |

-- |

|

|

Corrosion resistance |

Corrosion、acid、alkali、salt resistant |

Corrosive, easy to rust |

|

insulation |

insulation |

Conduction |

|

Mechanical strength |

Top force 2.5kN deflection 1.0cm |

Top force 2.5kN deflection 1.2cm |

|

Lateral force 0.5kN |

Top horizontal offset 7cm |

Top horizontal offset 7cm |

|

Weight |

light |

weight |

|

Eddy current effect (loss) |

no |

Large loss |

|

Manufacturing process is difficult |

easy |

Many processes and long cycle |

|

Cable outer sheath scraping test |

No visible damage |

There is a little visible damage |

|

Raw material |

Cheap, resource-rich |

More expensive, partially imported |

|

Maintenance |

Free maintenance |

5-7 years need to be repaired once |

|

Installation process is difficult or easy |

Short time and easy to install |

Long time, difficult to install |

|

Use life |

30 years |

10 years |

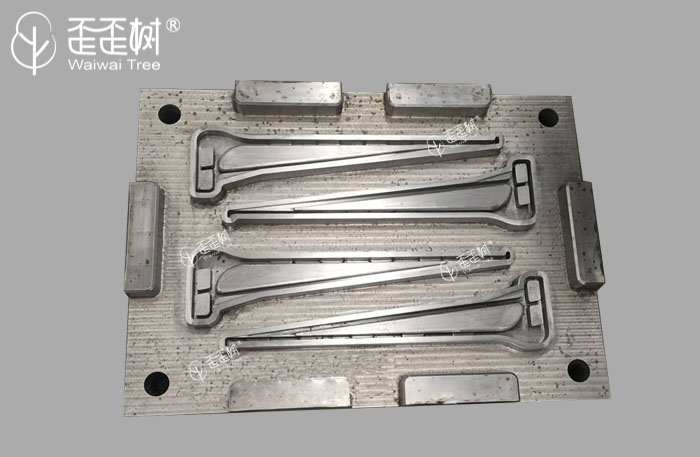

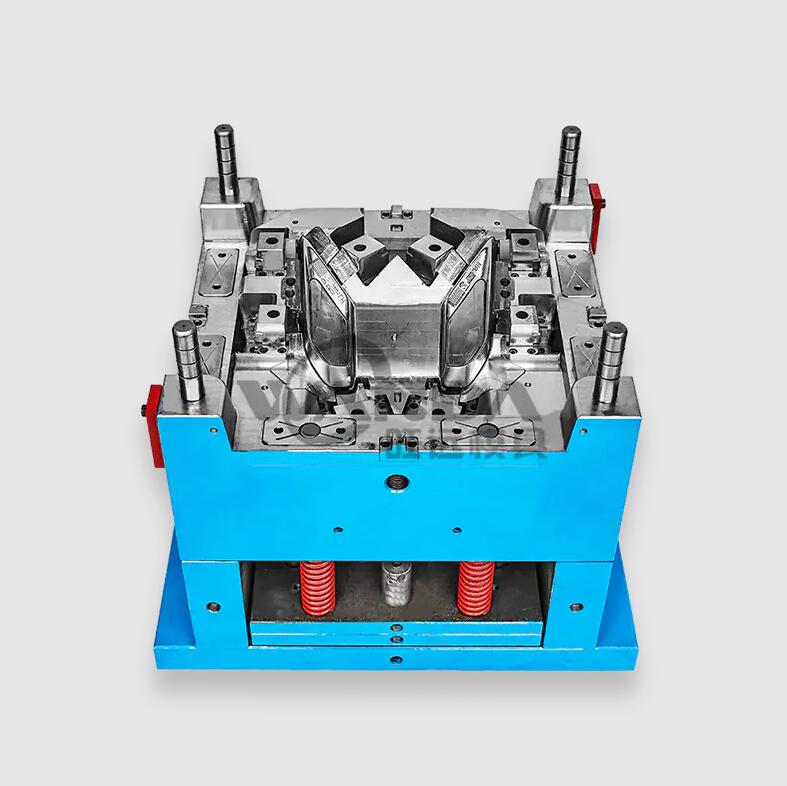

SMC and BMC compositerequire heating rather than cooling systems. The temperature of the mold is usually between 130 and 160. It is very important to keep the temperature of the mold and the exhaust gas when designing the mold. The mold is easier to fill, the product is not easy to be deformed, and the surface is better. Commonly used heating systems are steam, oil and electric heating rods.

Established in 2010 and located in Chengnan Development Zone, Luoshe Town, Huzhou City, Zhejiang Province, Zhejiang Aobang Technology Co., Ltd. has extensive bulk molding compound processand many refined testing laboratories as a spinal column in the industry. Whether at home or abroad, Zhejiang Aobang Technology Co., Ltd. can manufacture top quality bmc compoundmolds with advanced mold making concept, proprietary application technology and production technology. By the way, being a high-tech enterprise, it is a fact that this company enjoys a good fame in the new motor and energy automobile industry in Hangzhou.

Send product request

Other supplier products

| Auto Parts And Accessories | Auto Parts Description Parts made from sheet molding compound (SMC) are typically 25-35% lighter than steel parts and aluminum products of the same... | |

| BMC/SMC Mould | BMC/SMC MouldingDescription: We mainly use injection molding and pressure molding as the methods. When designing the flow channel and parting su... | |

| SMC Cable Braket | The SMC cablebracket is a combination consisting of a cable bracket, a post and a fixed pin. The material of the column and the pin is also made by... | |

| BMC, SMC, GRP, GFK Building & Decoration Materials | Building decoration materials, also known as building finishing materials, refer to the materials laid or painted on the surface of buildings to de... | |

| BMC/SMC Molds | Custom high Precision Compression/bulk molding compound manufacturingwith fast lead time BMC/SMC Mould Manufacturer We mainly use bmc injecti... |

Same products

| Precision And Durable Multi-Specification Automobile Buckle Mold | Seller: Yueqing Huangrong Mold Co., Ltd. | Automotive door panel clip frame molds are essential tools in this process, ensuring that the cli... | |

| Custom Motor Mold | Seller: 846123 | 90 Three-row High-Speed Progressive Stamping Mould Custom MotorMold () The 90 Three-row High... | |

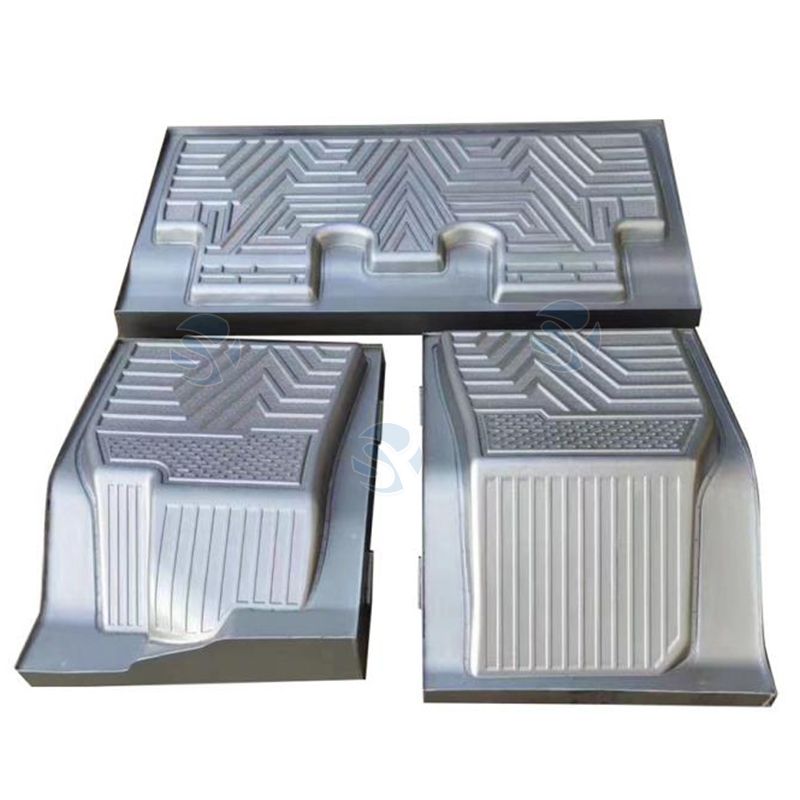

| Car Mat Aluminium Vacuum Mould | Seller: Hebei Shuiyuan Trading Co., Ltd | Product Description Vacuum molding is the most popular technology for shaping plastic raw mate... | |

| Auto Mould-Safe and Convenient Operation | Seller: Taizhou Wanda Plastic Mould Co.,Ltd. | Product Name Auto Parts Mould Brand Wanda Mould Model No specific Model Material S136/H1... | |

| SMC Cable Braket | Seller: ZHEJIANG AOBANG TECHNOLOGY CO.,LTD | The SMC cablebracket is a combination consisting of a cable bracket, a post and a fixed pin. The ... |