BMC, SMC, GRP, GFK Roof Tiles

What is gfk material?

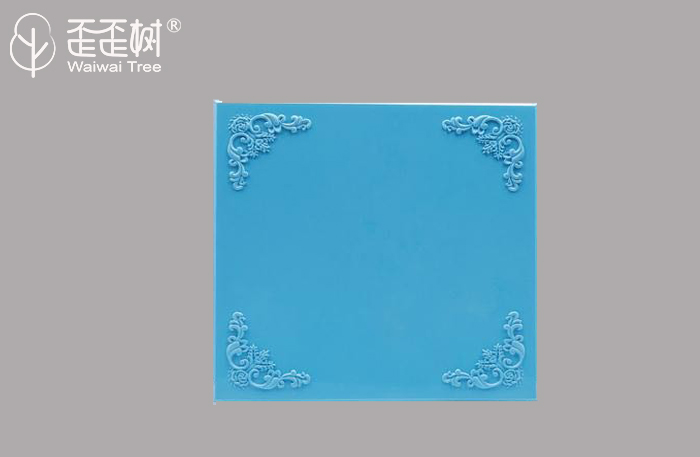

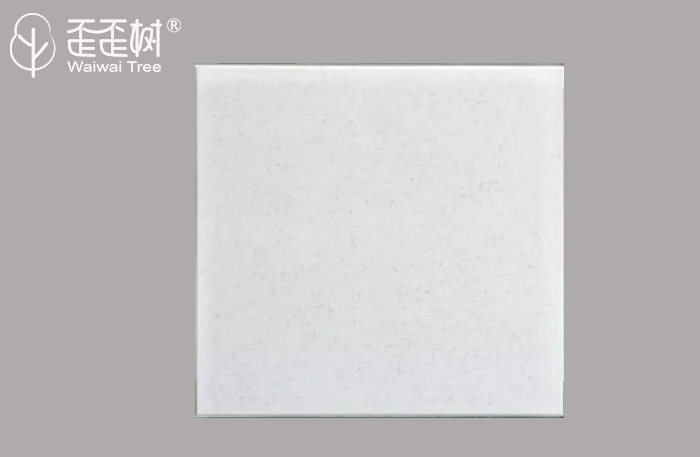

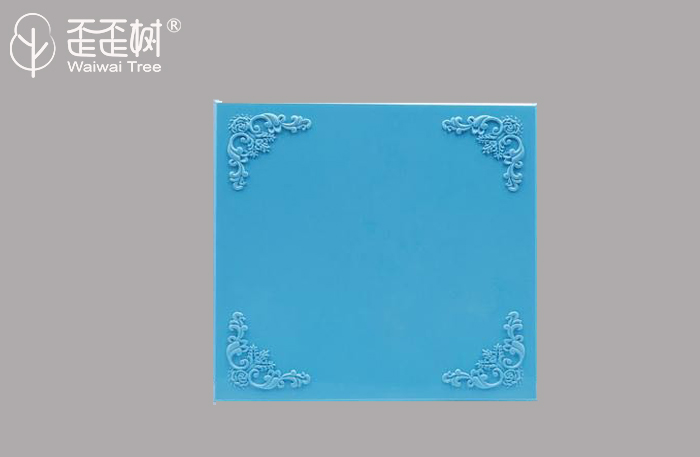

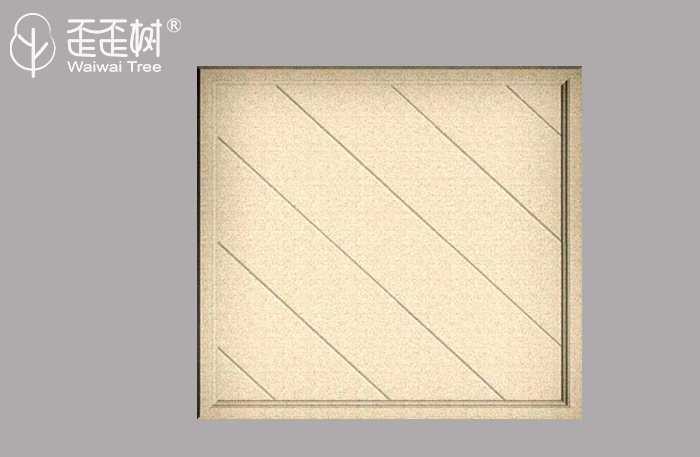

Aobang composite roofing tiles is divided into: BMC roofing tiles, SMC roofingtiles, GRP roof tiles, GFK roofing tiles.

Due to the excellent properties of BMC, SMC, GRP, GFK materials, it is the best choice for making roof tiles. BMC, SMC, GRP, GFK material is a composite material, mixed with polyester resin, chemical and mineral fillers, technical agents, usually reinforced with GFK fiberglass. It is an excellent material GFKfor outdoor applications. It has weather resistance and UV stability and has a service life of more than 30 years in outdoor environments. It absorbs almost no moisture, so it can isolate the moisture from the outdoors to the room. It is water and chemical resistant so acid rain does not affect the surface of the roof. Colors are easily mixed into the BMC, SMC, GRP, GFK material as a pigment, so colored tiles can be easily obtained and the color does not disappear during its lifetime.

BMC, SMC, GRP, GFK materials are also fire resistant. If there is no source of burning material around it, it will not spread and will immediately go out. Light weight and high strength are one of the biggest advantages of BMC, SMC, GRP, GFK materials. As the grp roof supplies, thisgfk materialhas a density of 1.7-2.0. It makes the tiles very light. Transportation costs, installation costs, etc. can be reduced. this materials make your roof tiles more colorful, longer lasting and more cost effective.

Advantage: Light weight, high strength, aging resistance, UV protection, acid and alkali resistance, waterproof and moisture proof, no fading, low thermal conductivity and energy saving.

Established in 2010 and located in Chengnan Development Zone, Luoshe Town, Huzhou City, Zhejiang Province, Zhejiang Aobang Technology Co., Ltd. has extensive bulk molding compound processand many refined testing laboratories as a spinal column in the industry. Whether at home or abroad, Zhejiang Aobang Technology Co., Ltd. can manufacture top quality composite molds with advanced mold making concept, proprietary application technology and production technology. By the way, being a high-tech enterprise, it is a fact that this company enjoys a good fame in the new motor and energy automobile industry in Hangzhou.

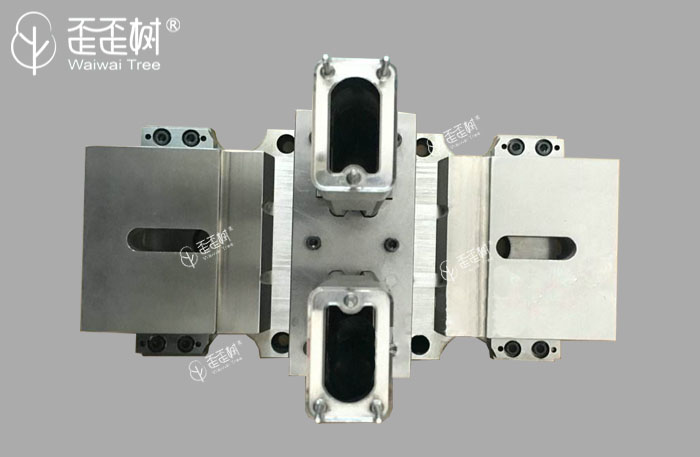

SMC and BMC compositerequire heating rather than cooling systems. The temperature of the mold is usually between 130 and 160. It is very important to keep the temperature of the mold and the exhaust gas when designing the mold. The mold is easier to fill, the product is not easy to be deformed, and the surface is better. Commonly used heating systems are steam, oil and electric heating rods.

Vacuum assisted systems for BMC and SMC molds: Products with Class A surfaces are usually vacuum-assisted, and the internal cavity and vacuum insulation of the mold are very important. The mold must have a sensor and a vacuum system to measure the mold temperature and pressure vacuum. Production SMC and BMC molds must guarantee high quality, long life and economy. Aobang Technology Co., Ltd.'s years of experience in the production of SMC and BMC molds and proficiency in machine, mold, material and process can ensure the maximum benefit of customers.

Send product request

Other supplier products

| BMC, SMC, GRP, GFK Roof Tiles | BMC, SMC, GFK, GRP roofing materialsare glassfiber reinforced plastic, also known as glassfiber roof, which are composed of resin and glassfiber. T... | |

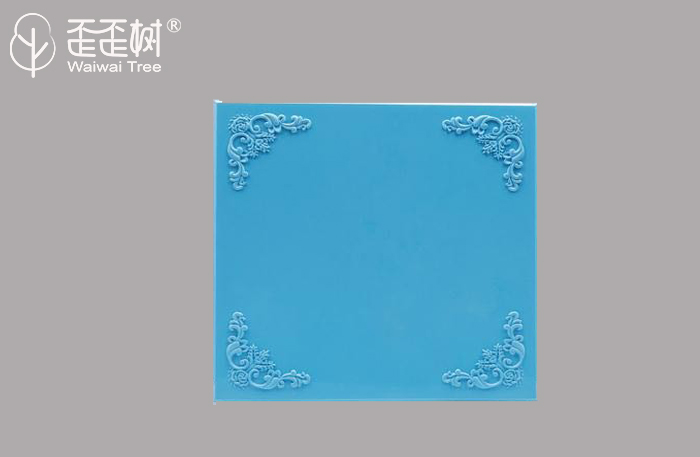

| BMC, SMC, GRP, GFK Wall Panel | BMC, SMC, GRP, GFK Wall Panel Composite wall panel is a new generation of high performance building partition board made of a variety of building ... | |

| BMC, SMC, GRP, GFK Roof Tiles | Aobang composite roofing tiles is divided into: BMC roofing tiles, SMC roofingtiles, GRP roofing tiles, GFK roof tiles. Do you konw what is gfk ... | |

| BMC/SMC Mould | BMC/SMC Moulding Description: We mainly use injection molding and pressure molding as the methods. When designing the flow channel and parting surf... | |

| BMC/SMC Molded Products | BMCSMCthermosetting plastic products are produced by plastic smcand BMC plastic molding process. Types of BMC/SMC Molded Products BMC/SMC Motor... |

Same products

| Precision And Durable Multi-Specification Automobile Buckle Mold | Seller: Yueqing Huangrong Mold Co., Ltd. | Automotive door panel clip frame molds are essential tools in this process, ensuring that the cli... | |

| Custom Motor Mold | Seller: 846123 | 90 Three-row High-Speed Progressive Stamping Mould Custom MotorMold () The 90 Three-row High... | |

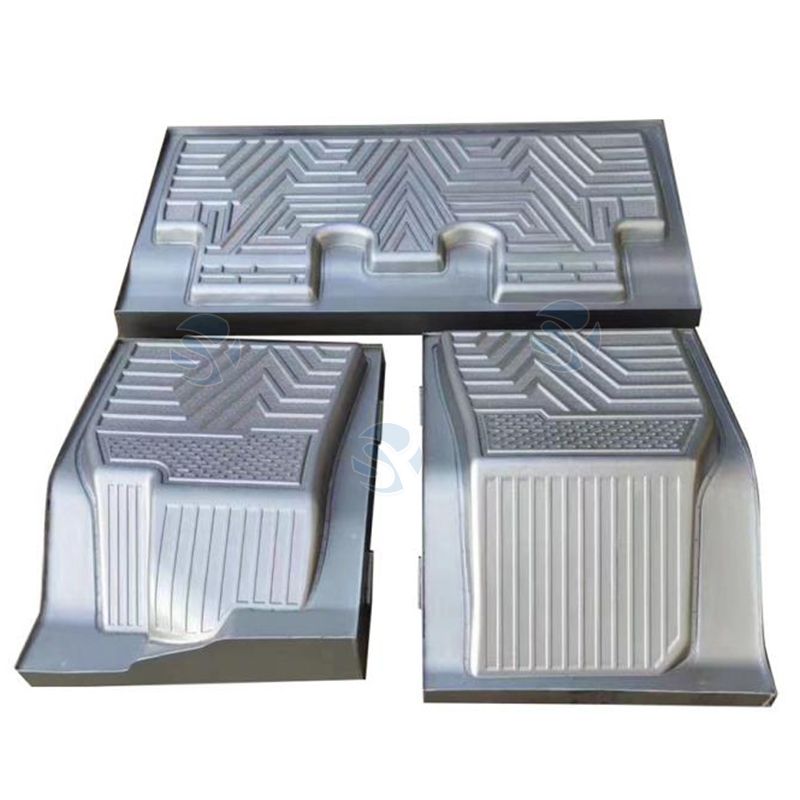

| Car Mat Aluminium Vacuum Mould | Seller: Hebei Shuiyuan Trading Co., Ltd | Product Description Vacuum molding is the most popular technology for shaping plastic raw mate... | |

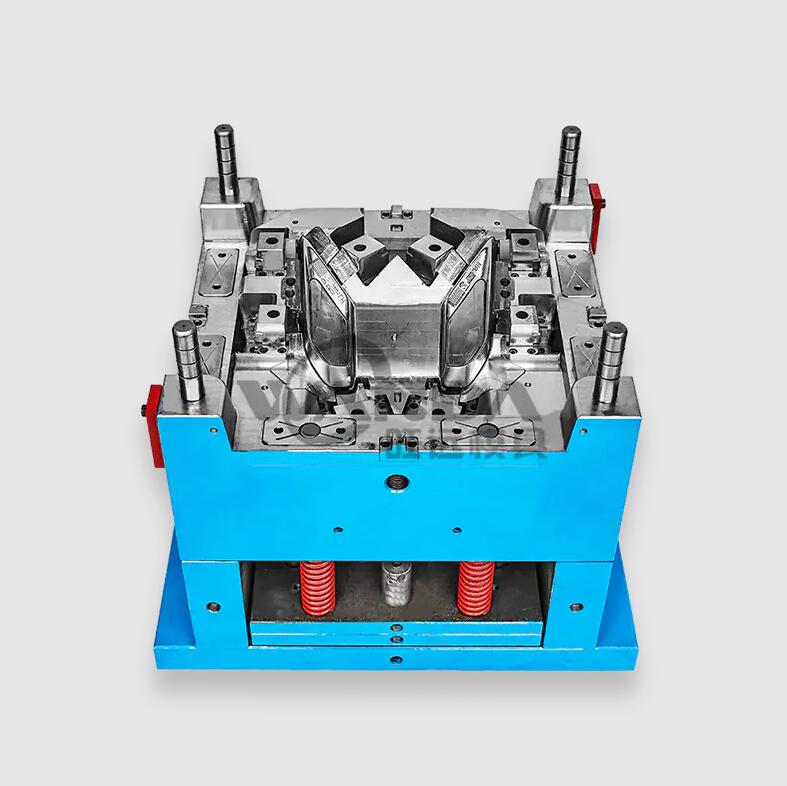

| Auto Mould-Safe and Convenient Operation | Seller: Taizhou Wanda Plastic Mould Co.,Ltd. | Product Name Auto Parts Mould Brand Wanda Mould Model No specific Model Material S136/H1... | |

| SMC Cable Braket | Seller: ZHEJIANG AOBANG TECHNOLOGY CO.,LTD | The SMC cablebracket is a combination consisting of a cable bracket, a post and a fixed pin. The ... |