LGFD Direct Driven Screw Compressor

Coupling connected, less energy consumption, less noise, ISO, CE certificates with a highly competitive price for various industrial projects.

Advantages of LGFD Direct Driven Screw Compressor:

1. Coupling driving system2. Highly competitive price3. Economic running costs4. ISO, GA, SGS certificates

LGFD Direct-driven Screw compressor design features:

First, the curved face of the rotors engaged fully, thus contributing to the formation of a hydrodynamic lubrication film, reducing the contact zone of the lateral leakage, improve compressor efficiency; as well as to improve the processing, test performance of the rotor.Second, using the design ideas of bigger rotor, bigger bearing, low-speed ", speed lower than other brands up to 30 ~ 50%, this could reduce noise and vibration, reducing the compressed air temperature and improve the rigidity of rotor and prolong its life, reduce sensitivity to the impurity and the oil carbide.Third, fully meet or exceed the national standard GB19153-2003 "air compressors energy efficiency limit !

1 Drives and electrics

The almost loss-free power transmission guarantees reliable, high-performance compressor operation. The regular maintenance requirement is reduced to lubrication of the motor. All the electronic components are brand products of leadingmanufacturers. rives and electrics.

2 Air end block – reliable centrepiece – Design in Germany

The centrepiece of Direct-driven Screw compressor is the air end, which is constructed and manufactured with the most modern production methods in China. The optimal air end for your compressor can be used on a modulating basis. In frequency-controlled units, where the operating pressure changes, adjustments can also be made on the frequency controller to optimally adjust the speed of the compressor to the compressor performance.

3 Electric motor

Only electric motors from well-known manufacturers of protection class IP54/IP23 are used in our Direct-driven Screw compressor. As a standard, the drive motors are monitored both thermally (via the thermistor of the motor) as well as electronically(overload protection via the frequency inverter).

4 Oil separation system

LGFD Direct-driven Screw compressor up to 132 kW are equipped with external separators that can be changed in a simple spin-off/spin-on process. Larger units have an internal separator cartridge. Due to the excellent separation efficiency of the system as a whole, the compressors can be used in the pressure range of 5.0 to 15.0 bar. Special pressures on request.

5 Oil circuit

The amount of oil in the LGFD Direct-drivenScrew compressoris determined in such a way as to extend the oil change intervals (depending on ambient conditions). An oil level sensor is integrated as standard and is read by the controller. All the units in this series have a horizontal oil separation vessel in which the oil is separated from the compressed air highly efficiently at low speeds.

Frequency inverters (optional)

The frequency converter minimises idle times and optimises supply with fluctuating compressed air requirements. Start-up peaks are avoided and the compressor’s delivery rate is controlled continuously – that saves electricity costs! The total costs for your compressed air supply are significantly reduced and investment costs are amortised in the shortest possible time.

website:

company:Shanghai Rotorcomp Screw Compressor Co., Ltd

contact:

Send product request

Other supplier products

| Air Treatment Systems | After-processing equipment of compressorISO, CE, TUV, ASME standard manufacturer producing quality Refrigerated air dryer, Desiccantair dryer for c... | |

| Rotorcomp NK Air End | Screw compact units Rotorcomp screw integratedair endfor screw compressor, ISO, TUV certificates, made in germany 100% with unique high-ef... | |

| LGFD Direct Driven Screw Compressor | Coupling connected, less energy consumption, less noise, ISO, CE certificates with a highly competitive price for various industrial projects. Adv... | |

| Oil free compressor | ISO 8573-1 Class 0 oil free compressor, in ISO,TUV,CE certificates with good price, 5 years warranty, patented unique design, more energy-saving ... | |

| Rotorcomp EVO Air End | RELIABLE AND VERSATILE Rotorcomp oil-injectedscrew air endscreate the heart of your compressor system. Used with our wide range of component... |

Same products

| Dental Impression Materials | Seller: Shandong Huge Dental Material Corporation | PERFIT teeth impression materialis a VPS impression material used to obtain precise and reliable ... | |

| TANABE SAUER SPERRE HATLAPA ATLAS COPCO | Seller: DOUBLE WIN INTERNATIONAL GROUP LIMITED | Double Win International Group., Ltd. specializes in providing domestic and foreign customers wit... | |

| Air Compressor | Seller: Xuanhua Taiye Drilling mechinery Co;Ltd. | As a professional air compressor supplier, we can select the drilling air compressor model and br... | |

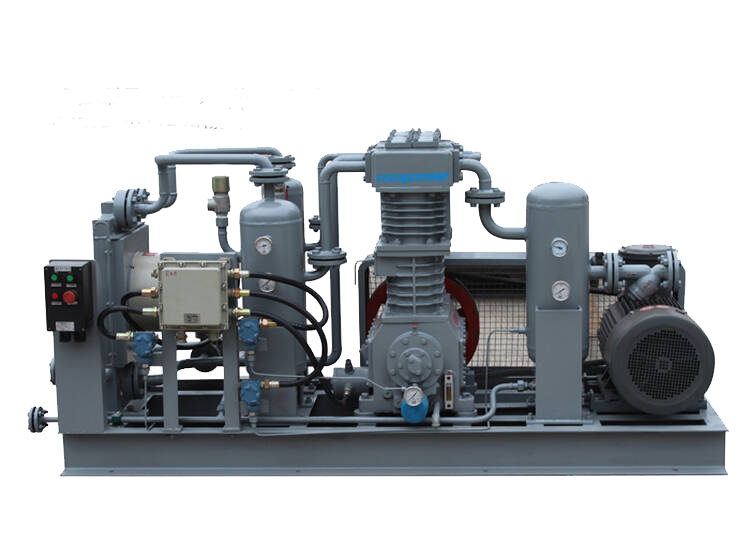

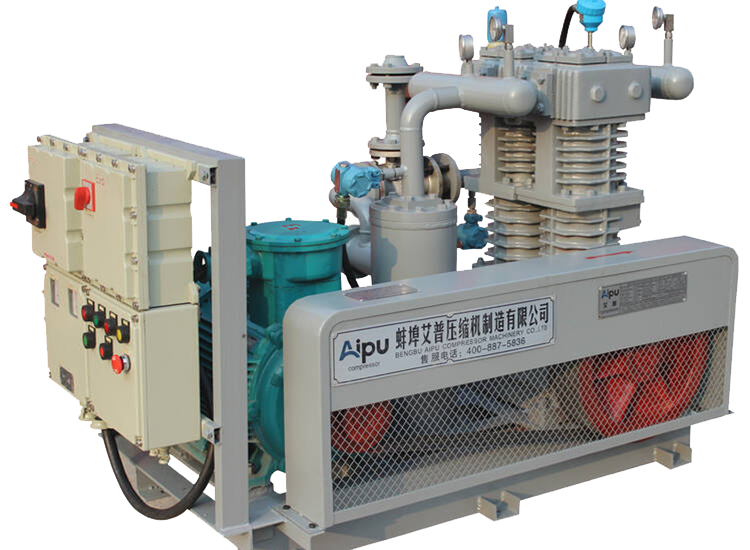

| Z-type BOG Compressor | Seller: Bengbu Aipu Compressor Manufacturing Co.,Ltd. | Oil and gas compressor manufacturers- Your professional supplier and reliable partner! Bengbu Ai... | |

| Z-type Ammonia Gas Compressor | Seller: Bengbu Aipu Compressor Manufacturing Co.,Ltd. | Gas Compressor Manufacturers- Your professional supplier and reliable partner! Bengbu Aipu Compr... |