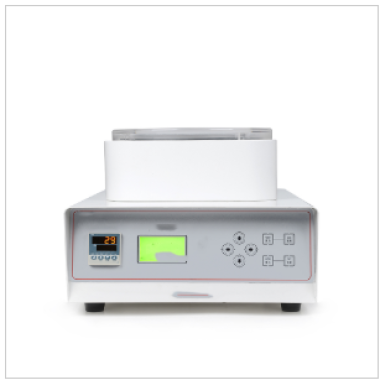

Photovoltaic module backplane peeling strength testing machine

The Photovoltaic Module Backplane Peeling Strength Testing Machine is a specialized device designed to evaluate the peeling strength of photovoltaic module backplanes, ensuring the durability and reliability of solar panels. This testing machine complies with the IEC 61730-2 standard, which is critical for assessing the safety and performance of photovoltaic modules.

This equipment is essential for manufacturers and quality control laboratories focused on photovoltaic modules, as it helps verify the adhesion strength of backplanes, which is vital for the longevity and safety of solar panels. By using this testing machine, users can identify potential weaknesses in module construction and improve product quality. The device is designed for ease of use and accuracy, making it a valuable tool in the photovoltaic industry. Please note that the information provided is intended for industry professionals and should be used as a reference.Buyers are advised to ensure they meet all relevant qualifications and regulatory requirements before purchasing.

Application

(1) Measurement of backplane peeling strength in framed and frameless PV modules

(2) Verification of adhesion quality for module encapsulants and backsheet materials

(3) Evaluation of module mechanical reliability during design and production stages

(4) Compliance testing for safety and durability assessment per IEC 61730-2

(5) Identification of potential defects in module lamination processes

Standards

(1) IEC 61730-2 – Photovoltaic (PV) Module Safety Qualification: Part 2 – Mechanical Testing

(2) Optional: ISO 178 – Plastics – Determination of Flexural Properties

(3) Optional: ASTM D1876 – Peel Resistance of Adhesives (T-Peel Test)

(4) CE Certification – Conformité Européenne

Features

High Precision Load Application: Rated load capacity of 500 N ensures accurate simulation of peeling forces.

Adjustable Peeling Method: 0–180° peeling angle accommodates a wide range of testing scenarios.

Digital Display: Real-time monitoring of test speed (50–500 mm/min) and applied force.

Consistent Glass Speed: Maintains 50±5 mm/min for reliable testing of PV module surfaces.

Maximum Stripping Force Measurement: Capable of measuring ≥200 N for backplane adhesion evaluation.

User-Friendly Operation: Simple setup with accurate, repeatable results, suitable for laboratory environments.

Parameters

| Parameter | Specification |

|---|---|

| Rated Load | 500 N |

| Travel Distance | 210 mm |

| Digital Display Test Speed | 50–500 mm/min |

| Peeling Method | 0–180° (adjustable) |

| Glass Speed | 50 ± 5 mm/min |

| Maximum Stripping Force | ≥200 N |

Accessories

(1) PV module clamps and mounting fixtures

(2) Digital force display unit

(3) Software for data acquisition and test result recording

(4) Calibration weights and verification tools

(5) User manual and compliance documentation

Test Procedures

Mount the PV module securely on the test fixture.

Set the desired peeling angle (0–180°) and test speed (50–500 mm/min) on the digital display.

Apply the rated load to initiate the peeling test.

Monitor real-time force and displacement via the digital display.

Record the maximum stripping force and peeling behavior data.

Repeat the test for multiple samples as required for statistical validity.

Analyze the results to evaluate backplane adhesion strength and consistency.

Maintenance Information

Regularly inspect clamps, fixtures, and load application components for wear or damage.

Calibrate digital display and load sensors periodically to maintain measurement accuracy.

Keep the test area clean and free from dust or moisture to prevent contamination.

Lubricate moving parts and guide rails as recommended by the manufacturer.

Store the machine in a dry, temperature-controlled environment when not in use.

Send product request

Other supplier products

| Carpet tuft length measuring instrument | Standard BS 4223:1989 (British Standard): Specifies methods for determining the pile length of cut-pile carpets, ensuring consistency in quality... | |

| Tensile and Shear Tester | Obtainable data includes tensile/shear rigidity, tensile energy, elongation rates, and recoverability for such targets as cloth, paper, non-woven f... | |

| Film Heat Shrinkage Tester | The film heat shrinkage rate tester is a device specifically designed to measure the shrinkage performance of film materials under heating conditio... | |

| Appliance Stability Tester | Product Introduction The device conforms to GB4706-1 Article 20.1. IEC60335-1 Article 20.1 and other standards. The device is composed of a workbe... | |

| Humidity Environmental Test Chamber | Features and Benefits 1.Wide Humidity & Temperature Range Offers precise control over humidity from 20% to 98% RH and temperature from -70&de... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | Seller: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | Seller: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | Seller: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | Seller: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | Seller: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |