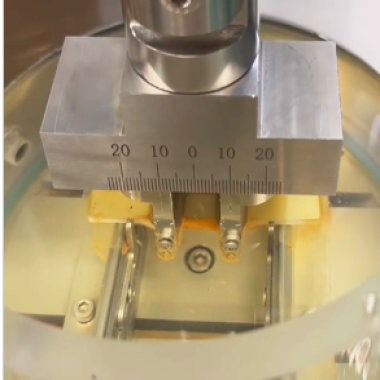

Rupture strength tester

The Rupture Strength Tester is designed to evaluate the mechanical pressure resistance and rupture strength of photovoltaic module components under controlled pressurization conditions. The system applies uniform hydraulic or pneumatic pressure to determine the failure threshold of module glass, backsheets, and encapsulation structures, supporting safety qualification and structural reliability assessment of photovoltaic modules.

Application

(1) Rupture strength testing of photovoltaic module front glass

(2) Pressure resistance evaluation of PV module backsheets and encapsulants

(3) Safety verification of single-glass and dual-glass photovoltaic modules

(4) Mechanical integrity assessment under simulated wind and snow loads

(5) Quality control and type approval testing in PV module manufacturing

(6) Failure analysis and material comparison in PV R&D laboratories

Standards

(1) IEC 61730-2 – Photovoltaic (PV) Module Safety Qualification – Requirements for Testing

(2) UL 61730 – Safety Standard for Photovoltaic Modules

(3) CE Certification (Conformité Européenne)

Features

(1) Wide Pressure Capability: Suitable for rupture testing of thin-film, crystalline silicon, and dual-glass PV modules.

(2) High-Resolution Pressure Control: Enables early detection of micro-cracking and progressive structural failure.

(3) Multi-Unit Measurement Interface: Supports kPa, psi, and kg/cm² for international testing requirements.

(4) Enhanced Safety Structure: Reinforced test chamber allows safe observation of specimen rupture.

(5) Automated Test Control: Preset pressure ramp and holding sequences reduce operator variability.

(6) Integrated Data Recording: Pressure–time curves and rupture values stored for traceability and analysis.

(7) Robust Construction: Stainless steel frame ensures long-term stability under repeated high-pressure operation.

Parameters

| Parameter | Specification |

|---|---|

| Pressure Range | 250–5,600 kPa (36–812 psi) |

| Pressure Resolution | 0.01 kg/cm² |

| Holding Pressure | 5 kg/cm² (adjustable) |

| Control Accuracy | ±1% FS (full scale) |

| Air Source Requirement | ≥6 kg/cm² (customer-provided) |

| Power Supply | 220V AC, 50/60Hz, single-phase |

| Dimensions | 560 mm (W) × 470 mm (D) × 550 mm (H) |

| Weight | 60 kg (net) |

Accessories

(1) Testing Fixtures: 1× specialized clamping fixture for 2–20 mm module thickness

(2) Membranes: 2× high-temperature rubber membranes (up to 300°C)

(3) Calibration Tools: 5× aluminum foil calibration discs

(4) Consumables: 85% glycerin solution for hydraulic calibration, disposable dust filters

(5) Safety Equipment: Safety goggles (ANSI Z87.1), emergency pressure release key

(6) Documentation: Multilingual quick-start guide and IEC/UL compliance certificates

Test Procedures

(1) Install the PV module specimen securely into the clamping fixture.

(2) Select pressure unit, ramp rate, and holding parameters via the touchscreen interface.

(3) Initiate pressurization and monitor real-time pressure increase.

(4) Maintain holding pressure as specified or continue ramping until rupture occurs.

(5) Record rupture pressure, pressure–time curve, and failure mode automatically.

Maintenance Information

(1) Inspect sealing membranes and clamping fixtures regularly for wear or deformation.

(2) Verify pressure sensor calibration at scheduled intervals.

(3) Clean the test chamber after each rupture test to remove debris.

(4) Check safety valves and electronic cut-off functions before routine operation.

(5) Store the tester in a clean, dry environment to maintain long-term accuracy.

Send product request

Other supplier products

| Athletic Footwear Shock Attenuating meter | Standard SATRA TM142 ASTM F1614 ASTM F1976 Product Advantages 1. Uncompromising Precision Hemispherical Impactor: 45mm diameter (37.5mm radiu... | |

| Bone Cement Four-Point Bending Fatigue Tester | Standard YY/T 1429 (China): Specifies four-point bending fatigue tests for acrylic resin bone cements under quasi-static and cyclic loading. ISO ... | |

| Carpet Peel & Tuft Test device | Product Details For tufted carpets or traditional carpets, an important parameter is the retention performance of their tufts. Poor - quality car... | |

| Syringe slide performance test device | Introduction: 5.7-inch (120 x 90) single color LCD touch screen, Chinese menu display. The nominal capacity of the syringe is selected by the ke... | |

| Suture Needle Sharpness Intensity Tester | The Sharpness and Strength Tester for Suture Needles is a device specifically designed to detect the sharpness and strength of medical suture needl... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | Seller: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | Seller: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | Seller: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | Seller: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | Seller: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |