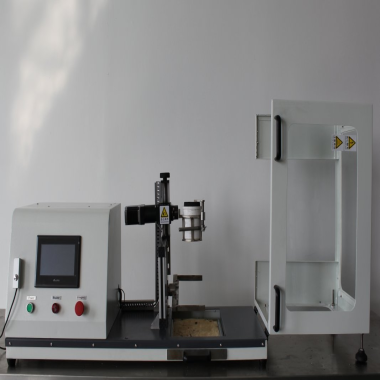

Sliding bearing PV friction testing machine

The testing machine can monitor the changes in friction force and the wear condition of the sample surface in real time during the test, and also precisely control and monitor various parameters of the testing machine in real time.

Application

The sliding bearing PV friction testing machine is primarily used to evaluate the friction and wear performance of engineering plastics, powder metallurgy materials, alloy bearings, and other materials under sliding friction conditions. By simulating different friction conditions, such as variations in load, speed, time, friction pair materials, surface roughness, and hardness, this testing machine can determine the PV value (the product of pressure and velocity, used to represent the load-carrying capacity of sliding bearings), as well as the optimal clearance and lubrication medium.

Standard

GB 7948-1987:Test method for PV limit of plastics bearings

JB/T 7381-2010:Powder metallurgy oil-retaining bearings - Determination of PV value

Working conditions

(1)The tester works normally under the following conditions:

(2)Within the range of room temperature 10℃~35℃.

(3) In an environment where the relative humidity is not greater than 80%.

(4) no vibration around, no corrosive media and no strong electromagnetic interference in the environment;.

(5) The fluctuation range of power supply voltage should not exceed ±10% of the rated voltage, and the fluctuation of frequency should not exceed 2% of the rated frequency; and

(6) Correctly installed on a firm foundation with a levelness of 0.2/1000.

Feature

High-precision testing: Ensures the accuracy of test results through precise control and real-time monitoring.

Wide range of applications: Suitable for various fields, including automotive manufacturing, aerospace, and mechanical engineering.

Multifunctionality: Capable of performing tests under different lubrication and load conditions.

Data processing: Test data can be displayed in real time, and corresponding data curves can be plotted for easy analysis and storage.

User-friendly: The equipment is easy to operate, making it suitable for use in research institutions, universities, and research institutes.

Parameters

| Description | Details |

|---|---|

| Test force (radial) loading range | 0 - 15000N |

| Force value accuracy error | ≤ ±1% |

| Spindle speed | 0 - 2000r/min, stepless speed regulation |

| Maximum speed error | ±2r/min |

| Measuring range of friction torque | 0 - 50Nm |

| Relative error of torque display value | ≤ ±2% |

| Temperature measurement range | Room temperature - 300℃ |

| Spindle taper; Friction sub-diameter; Standard specimen size | 1:7; 35mm; 39mm (outer diameter) * 35mm inner diameter * 35mm length |

| Test time control range | 0 - 999999S, arbitrary settings |

| Radial runout of spindle | ≤ ±0.01mm |

| Test cycle control range | 1 - 999999r, arbitrary setting |

| Control conditions | Fixed speed variable load; set test force, test time (or number of revolutions), test speed, loading interval time, loading gradient, etc. The test machine automatically controls shutdown conditions such as set time, friction coefficient, friction temperature, etc., and shuts down automatically. Real-time display of test parameters during the test process, including test force, friction torque, friction coefficient, number of revolutions, temperature, time, etc. Automatic calculation of test PV value, wear amount, and other data results, and output of test reports |

| Friction vice (steel bushing) | 45# steel quenched and tempered, hardness HRC40 - 45. or customized according to customer requirements |

| Whole machine power | About 8.5KW |

| Weight of main machine | About 800KG |

| Main machine size | About 12006001000 (units not specified, assumed to be mm) |

Accessoriess

High-temperature oil reservoir

Room-temperature oil reservoir

Pin-on-disk friction pair

Four-ball friction pair

Thrust ring friction pair

Lifting screw

Chuck pull rod

Spring collet

Vibration damping pads, etc.

Test Procedures

Sample Preparation: Load the sliding bearing sample to be tested onto the test rig, ensuring its surface is clean and smooth.

Load Application: Apply a specific force or pressure to the sample surface using the loading system, simulating the load conditions under real working conditions.

Start of Test: Start the test machine control system, controlling the movement speed of the test rig and the load changes according to preset conditions, and begin simulating the friction and wear process.

Data Acquisition and Analysis: Collect and record data such as friction force, load changes, and sample surface morphology in real time, and perform analysis and comparison to evaluate the friction performance and wear resistance of the sliding bearing.

Send product request

Other supplier products

| Catheter Flow Meter | The Catheter Flow Meter is specifically designed for measuring the water flow rate of medical catheters, including non-vascular catheters, intravas... | |

| Photovoltaic module insulation resistance tester | Standard IEC 61215: Terrestrial Photovoltaic (PV) Modules – Design Qualification and Type Approval UL 61730: Safety Standard for Photovolta... | |

| Molten Metal Penetration Resistance Tester | Standard ISO 9185(Protective Clothing - Assessment of Resistance to Molten Metal Splash) ASTM F955(Standard Test Method for Evaluating Heat Tra... | |

| Safety Helmet Impact Acceleration Tester | The safety helmet impact acceleration tester is an instrument used to test the performance of safety helmets when subjected to impact. It can simul... | |

| Textile Thermal Insulation Property Tester | Standard GB/T 41560-2022 (China): Specifies thermal resistance testing protocols for protective clothing and industrial fabrics. BS 6526:1998 (... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | Seller: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | Seller: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | Seller: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | Seller: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | Seller: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |