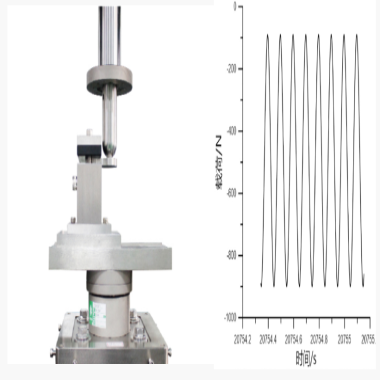

Oxidizing Solids Tester

Conforms to UN Recommendations on the Transport of Dangerous Goods - Manual of Tests and Criteria 34.4.1 Test O.1: Test for oxidizing solids, 34.4.3 Test O.3: Test for oxidizing solids by weight and GB/T 21617-2008 Test Methods for Oxidizing Solids of Dangerous Goods.

Applications

This testing instrument is used to determine the potential of a sample to increase the combustion rate or intensity of a certain combustible substance when mixed with it. The combustion rate can be determined by the combustion time test or gravimetric analysis, thereby confirming its packaging category. It is applicable to solid substances.

Standards

GB/T 21617-2023:Dangerous goods - Flammable solids - Test method for autoignition temperature

GB/T 21617-2008:Dangerous goods - Flammable solids - Test method for autoignition temperature

Features

1. It adopts an embedded processor and the Windows CE operating system.

2. With an 8 - inch liquid - crystal touch screen, it can display the test status in real - time.

3. It is compatible with both O.1 standard and O.3 standard.

4. It uses full - automatic photoelectric detection technology to reliably detect combustion phenomena.

5. It has a full - automatic weighing detection by balance, which automatically records the mass loss during the combustion process.

6. It is equipped with a mold made of standard metal wire.

7. It can automatically detect the breakage of metal wires and provide audible and visual alarms.

8. It has a high - precision temperature and humidity detection function to effectively collect environmental temperature and humidity data.

9. During the test process, it displays the running time and test animation images in real - time.

10. It supports remote - controlled ignition to ensure the safety of personnel during the experiment.

11. The test process is fully automated, requiring no manual intervention. It supports functions such as parameter setting, data storage, and report viewing.

12. It is equipped with a temperature and humidity module to monitor the temperature and humidity of the test environment in real - time.

Technical Parameters

| Working Environment | (5~40)℃, <85%RH |

| Heating Method | Standard shape inert metal wire heating |

| Heating Wire Power | 150W±2W |

| Detection Method | Infrared sensor array detection method or balance weighing detection method |

| Balance Weighing Accuracy | ±0.1g |

| Ambient Temperature Measurement Range | -10℃~+60℃ |

| Ambient Temperature Measurement Accuracy | ±0.5℃ |

| Ambient Humidity Measurement Range | 5%RH~95%RH |

| Ambient Humidity Measurement Accuracy | ±5.0%RH |

| Timing Display Resolution | 1s |

| Timing Accuracy | ±7ms/Min |

| Test Plate | Made of corundum, 150mm long, 150mm wide, 6mm thick |

| Sample Making Molds | Made of PTFE, inner diameter 70mm, angle 60° cone |

Accessoriess

1. Core Operating Components

Test Carrier Components: Standard metal wire mold (compatible with UN O.1/O.3 and GB/T 21617 standards, used for loading oxidizing solid samples and reference materials);

Detection Components:

Fully automatic photoelectric detection device (reliably identifies combustion phenomena);

Metal wire breakage detection sensor (in conjunction with an audible and visual alarm device);

High-precision temperature and humidity detection sensor (collects ambient temperature and humidity data);

Weighing Unit: Integrated high-precision balance (automatically records mass loss during combustion);

Control and Display Components: 8-inch LCD touchscreen (equipped with Windows CE system, displays test status in real time);

Safety Components: Audible and visual alarm device (triggers warnings in case of metal wire breakage or abnormalities).

2. Auxiliary Components

Sample Processing Components: Sample spoon (for quantitatively taking oxidizing solid samples), standard reference materials (e.g., dried cellulose, matching the O.1/O.3 standard control sample);

Calibration and Maintenance Components: Balance calibration weights (calibrates weighing accuracy), metal wire calibration components (verifies breakage detection function);

Data Management Components: USB flash drive (exports test data and reports).

Test Procedures

1. Sample and Control Preparation

Grind and sieve the oxidizing solid sample to be tested (ensuring the particle size meets the standard requirements);

Prepare the control (e.g., dried cellulose) according to the test standard (O.1 or O.3), and weigh the sample and control in the specified proportions (O.1 is a sample-cellulose mixture, O.3 is a sample prepared by weight ratio).

2. Instrument Preparation

Connect the power supply and start the instrument; the embedded processor will automatically complete a fault self-check;

Calibrate the integrated balance with standard weights to confirm that the temperature and humidity sensor and photoelectric detection device are functioning properly;

Select the test mode (“O.1 Standard Mode” or “O.3 Standard Mode”) via the 8-inch touchscreen.

3. Sample Loading and Adjustment

Load the prepared sample and control into the standard metal wire mold and fix the mold to the designated test position on the instrument;

Confirm that the metal wire is within the monitoring range of the fracture detection sensor, and close the test chamber.

4. Start Automatic Testing

Set the test parameters (e.g., combustion monitoring duration) on the touchscreen and click "Start"; The instrument automatically records the initial mass of the sample, then starts the test process, monitoring combustion phenomena, mass loss, and the state of the metal wire in real time.

5. Test Process and Judgment

During the test, if the metal wire breaks, the instrument triggers an audible and visual alarm and records the corresponding status; After the test, the instrument automatically calculates the combustion duration and mass loss data, and determines the oxidizing power level of the sample according to UN/GB standards.

6. Completion and Data Export

After the test chamber cools, remove the mold and clean the sample residue; Export the test data, ambient temperature and humidity records, and oxidizing power determination report to a USB flash drive via the touchscreen; Turn off the instrument power to complete the operation.

Send product request

Other supplier products

| Rubber Resilience Tester | Standard Complies withISO 4662:1986(international),JIS K6255(Japan), andGB/T 1681(China) standards for standardized resilience testing of vulcaniz... | |

| Battery Powder Compaction Density Measurement System | The Battery Powder Compaction Density Measurement System is a precision testing system designed to determine the tapped density and compaction beha... | |

| Solid Auto - ignition Point Tester | This tester determines the self - ignition characteristics of solid chemical products by placing the substances in a 20mm - side - length cubic wir... | |

| Femoral Stem Neck Prostheses Fatigue Tester | Standard YY/T 0809.6 (China): Specifies neck fatigue testing for femoral stems in partial/total hip arthroplasty. ISO 7206-6 (International): Def... | |

| Wire Fire Resistance+ Mechanical Shock Testing Machine,IEC 60331 | Wires and cables that are hard to catch on fire and have the ability to prevent or delay the spread of fire are usually referred to the wires and c... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | Seller: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | Seller: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | Seller: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | Seller: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | Seller: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |