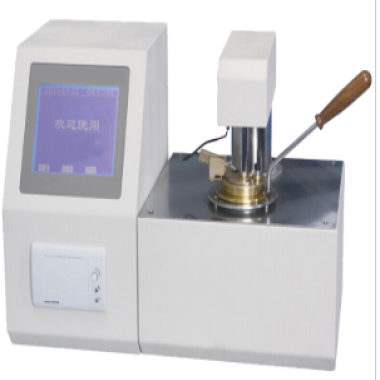

Cleveland Open Cup Flash Point Tester

The instrument can automatically test the flash point and ignition point of petroleum products (the ignition point of oil exceeding 80 ° C, except crude oil and petroleum fuel), and can be compared with the test results of manual instruments, very simple and convenient.

Meets the ISO 2592 standard. Its programmable logic controller and touch screen (5.5 ") help automate testing, and managing test results is easy.

Application

Covering Multiple Industries, Driving Safety and Efficiency Upgrades

Petrochemical Industry

Refining and Quality Inspection: Monitoring flash point changes in processes such as crude oil distillation and lubricant blending to ensure product quality. For example, a refinery reduced the lubricant rejection rate from 2% to 0.5% by real-time flash point detection.

Asphalt Production: Testing asphalt flash point to meet JTJ052 standards and prevent spontaneous combustion risks during transportation.

Power and Energy Sector

Transformer Oil Testing: Determining the flash point of transformer oil according to DL/T 596 standard to assess its insulation performance and aging degree. For example, a power plant found that the flash point of a transformer oil had dropped to 130℃ through testing, and timely replacement prevented equipment failure.

New Energy Research and Development: Studying the flash point characteristics of new fuels such as biodiesel and hydrogen carriers to promote the application of clean energy.

Transportation Industry

Railways and Aviation: Detecting the flash point of locomotive oil and aviation lubricants to ensure operational safety. For example, an airline found that the flash point of a batch of aviation fuel was too low through testing, and suspended the use of that batch of fuel to avoid flight accidents.

Standard

ASTM D92:Standard Test Method for Flash and Fire Points by Cleveland Open Cup

IP 36. 403:Determination of Flash and Fire Points by Cleveland Open Cup Method (IP 36/403)

ISO 2592:Determination of flash and fire points - Cleveland open cup method

AFNOR T60-118:Petroleum products - Determination of flash and fire points - Cleveland open cup method (AFNOR T60-118)

EN 22592:Petroleum products - Determination of flash and fire points - Cleveland open cup method (EN 22592)

DIN 51376:Testing of mineral oils; determination of flash and fire point by Cleveland open cup

Feature

Automates the testing process for both flash point and ignition point, reducing operator intervention and potential for error.

Provides highly repeatable and reproducible test results, crucial for reliable product characterization.

Designed to comply with the ISO 2592 standard (Cleveland Open Cup Method).

Features an intuitive 5.5-inch color touch screen and programmable logic controller (PLC) for easy operation and test management.

Simplifies data processing and result management, enhancing laboratory efficiency.

Offers a convenient and efficient alternative to traditional manual testing methods.

Equipped with safety features necessary for handling flammable petroleum products.

Product Features:

Automatic Test Procedure: Conducts the heating, test flame application, flash detection, and ignition point determination automatically.

Programmable Logic Controller (PLC): Enables precise control over the test parameters and sequences.

Touch Screen Interface (5.5"): Provides a user-friendly interface for setting up tests, monitoring progress, and viewing results.

Data Processing and Management: Capable of processing test data and facilitating easy management of results.

Micro Printer: For direct printing of test results for record-keeping.

Integrated Heating System: Precisely controls the sample temperature rise rate.

Automatic Ignition System: Applies the test flame at specified intervals.

Flash/Ignition Detection System: Reliably detects the flash and sustained ignition.

Parameters

| Description | Details |

|---|---|

| Dimensions | 550(W) x 400(D) x 320(H)mm |

| Table size | 1000(W) x 600(D) x 800(H)mm (assuming the "1.000" is a typo and should be "1000") |

| Power supply | AC 220V 50/60Hz, 15A |

| Weight | 30kg |

| Instruction manual | Available |

| Exhaust | Minimum 50L/s |

| Tools | Propane gas, vacuum cleaner |

Accessoriess

Thermal fuse

Gas hose

Heating plate

AC power cord

Instruction manuals, etc.

Test Procedures

Sample Preparation: Heat the sample until it becomes fluid, then pour it into the cup up to the marked line, avoiding contamination of the cup walls.

Heating Control: In the initial stage, heat rapidly at 14-17℃/min, then slow down when the temperature reaches 56℃ below the expected flash point.

Critical Stage: When the temperature is 28℃ below the expected flash point, control the heating rate to 5.5℃/min ± 0.5℃.

Ignition Determination: Sweep a flame across the cup opening every 2℃ increase in temperature. Record the temperature when a transient blue flame appears and immediately extinguishes.

Test Completion: Clean the equipment and switch off the power supply

Send product request

Other supplier products

| Xenotest | Light Fastness Testers | Standard Compliance AATCC TM16-2004 Colorfastness to Light AATCC TM16.3 Colorfastness to Light ASTM D2565 Standard Practice for Xenon Arc Expo... | |

| Intramedullary Nails Static Four-point Bending Tester | Standard YY/T 0591 (China): Standard for static four-point bending tests of lockable intramedullary nails. ASTM F1264 (International): Specificat... | |

| Timken Test Machine | The extreme pressure friction testing machine mainly consists of a main frame, a spindle transmission system, a test force loading mechanism, a lub... | |

| Mask respiratory resistance tester | The Mask Respiratory Resistance Tester is designed to measure the inhalation and exhalation resistance of respirators and masks under controlled co... | |

| Contact Coolness Tester STD-QM | The sensation of coldness or warmth when skin touches an object is referred to as the "coldness and warmth feeling". The feeling of coldness or war... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | Seller: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | Seller: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | Seller: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | Seller: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | Seller: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |