Contact Lens Luminous Transmittance Analyzer

The Contact Lens Luminous Transmittance Analyzer is a precision instrument designed to measure the spectral transmittance of soft and hard contact lenses, including hydrogel, silicone hydrogel, artificial cornea, RGP, and Ortho-K lenses. The instrument integrates a built-in integrating sphere to ensure highly accurate measurements that comply with international standards. It features a specially designed lens clamp that prevents deformation, enabling reliable and repeatable results. This analyzer is ideal for manufacturers, laboratories, and research institutions focusing on optical performance evaluation and quality control of contact lenses.

Application

(1) Measurement of spectral transmittance for soft contact lenses (hydrogel/silicone hydrogel/artificial cornea).

(2) Measurement of spectral transmittance for hard contact lenses (RGP, Ortho-K).

(3) Quality control in contact lens manufacturing.

(4) Research and development of new lens materials with specific optical properties.

(5) Verification of compliance with national and international standards for ophthalmic optics.

(6) Optical characterization for product certification and regulatory submission.

Standards

(1) GB/T 11417.5 – Ophthalmic optics – Contact lenses – Spectral transmittance test method.

(2) ISO 18369 – Ophthalmic optics – Contact lenses – Requirements and test methods.

(3) ANSI Z80.20 – American National Standard for Contact Lens Optical Properties.

(4) ISO 8980-4 – Ophthalmic optics – Lenses for correction of vision – Part 4: Transmittance specifications.

(5) IEC 61010 – Safety requirements for laboratory and measuring equipment.

Features

(1) Built-in integrating sphere ensures uniform illumination and accurate lens transmittance measurement.

(2) Specially designed lens clamp prevents deformation for both soft and hard lenses.

(3) Wide spectral range (280–780 nm) for comprehensive optical evaluation.

(4) Adjustable wavelength interval (1–10 nm) for high-resolution measurement.

(5) High measurement accuracy with transmittance repeatability <1% and absolute error <1%.

(6) Supports measurement in air or solution (pure water or standard saline).

(7) User-friendly software interface compatible with Windows 7/8/10/11.

(8) Data output via USB for easy integration with laboratory information systems.

Technical Parameters

| Parameter | Specification |

|---|---|

| Measurement Medium | Air, solution (pure water or standard salt solution) |

| Measuring Aperture | 6 mm |

| Maximum Lens Diameter | 18 mm |

| Wavelength Range | 280–780 nm |

| Wavelength Interval | 1–10 nm adjustable (default 5 nm) |

| Transmittance Repeatability | <1.0% |

| Absolute Transmittance Error | <1.0% |

| Instrument Size (W×D×H) | 600 × 440 × 190 mm |

| Weight | ~26.5 kg |

| Power Supply | AC 100–220 V, 50 Hz, 150 W |

| Operating System | Windows 7/8/10/11 |

| Data Interface | USB |

Accessories

(1) Lens clamp for soft and hard lenses.

(2) Integrating sphere (built-in).

(3) Calibration standards for spectral transmittance.

(4) Software suite for data acquisition and analysis.

(5) USB data cable.

(6) User manual and compliance certificates.

Test Procedures

Place the contact lens into the special clamp to ensure zero deformation.

Select the measurement medium (air or solution).

Set the desired wavelength range and interval in the software.

Initiate the spectral transmittance measurement.

Record the transmittance data and verify against specifications.

Repeat measurements for additional lenses or multiple trials as required.

Export results via USB for documentation or further analysis.

Maintenance Information

(1) Clean the lens clamp and integrating sphere regularly to prevent contamination.

(2) Calibrate the instrument periodically using standard reference filters or lenses.

(3) Ensure the measurement medium is free of bubbles or impurities.

(4) Avoid direct sunlight and dust accumulation on optical components.

(5) Store the instrument in a dry, temperature-controlled environment.

(6) Update software and firmware as recommended by the manufacturer.

Send product request

Other supplier products

| Initial Bonding Strength Testing Apparatus | The initial - tack tester, also known as the initial - tack property tester or adhesive tape tackiness tester, is an instrument specifically used t... | |

| Protective Clothing Liquid Static Pressure Tester | Standards GB24540-2009,LFY-252 Instrument use The acid-proof clothing material anti-seepage acid static acid pressure tester is used to measure ... | |

| Rapid screening Calorimeter | The rapid - screening calorimeter is a professional calorimetric instrument for the quick assessment of reaction thermal hazards. It supports multi... | |

| Safety Helmet Chin-strap Strength Tester | Standard GB/T 2812-2006: Safety Helmets GB/T 2811-2019: Head Protection – Vocabulary and Test Methods Equivalent Compliance: ISO/EN 397 (I... | |

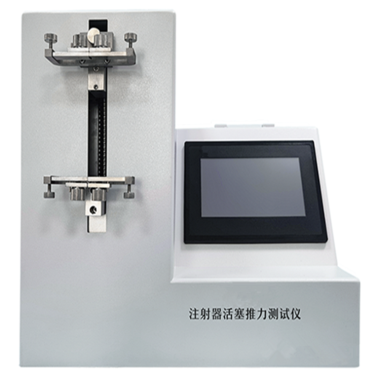

| Syringe piston thrust tester | Product introduction The syringe piston thrust tester is a kind of high precision and high stability measuring equipment, which is used to measure... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | Seller: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | Seller: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | Seller: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | Seller: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | Seller: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |