Rubber non-rotor vulcanization Tester

The Rubber Non-Rotor Vulcanization Tester is a precision instrument designed for the rubber processing industry to monitor and control rubber material quality. It provides rapid inspection and supports rubber basic research and formulation optimization. The tester can accurately measure scorch time, positive vulcanization time, vulcanization index, and torque parameters (maximum and minimum), offering essential data for quality control, R&D, and formula development.

Applications

(1) Rubber compound quality control: Rapid assessment of rubber material properties during production.

(2) Rubber R&D: Testing new rubber formulations and additives.

(3) Vulcanization process optimization: Determining optimal curing conditions.

(4) Material comparison: Evaluating performance differences between batches or suppliers.

(5) Rubber laboratory testing: Suitable for research institutes and industrial laboratories for basic rubber studies.

Standards

(1) ASTM D5289-95 — Standard Test Method for Rubber Property—Vulcanization Using a Moving Die Rheometer

(2) ISO 6502-1999(E) — Rubber, Vulcanized or Thermoplastic—Determination of Cure Characteristics

(3) GB/T 16584-1996 — Rubber—Determination of Cure Characteristics Using a Non-Rotating Rotor Rheometer

Advantages

(1) Accurate vulcanization measurement: Determines scorch time, positive cure time, vulcanization index, and torque with high precision.

(2) Supports formula optimization: Provides reliable data for rubber compound development.

(3) Standard compliant: Meets ASTM, ISO, and GB/T international and national standards.

(4) User-friendly operation: Simple control interface for temperature and time settings.

(5) Stable and durable: Designed for long-term use in laboratory and production environments.

Technical Parameters

| Item | Specification |

|---|---|

| Temperature measurement range | 0–200℃ |

| Temperature setting range | 0–200℃ |

| Temperature display range | 0–200℃ |

| Set time range | 0–200 minutes |

| Torque measuring range | 0–5 N·m, 0–10 N·m, 0–20 N·m |

| Swing frequency | 100 times/min (≈1.7 Hz) |

| Power supply | AC 220V ±10%, 50 ±1Hz, must be grounded |

| Compressed air | 0.32 MPa, controlled by pneumatic valve |

| Ambient conditions | Temperature 0–40℃, RH <80%, no corrosive gases |

Accessories

(1) Main tester ×1

(2) Pneumatic control valve ×1

(3) Power cable ×1

(4) Instruction manual ×1

Test Procedure

(1) Connect the power supply and compressed air source.

(2) Set the desired test temperature and curing time on the control panel.

(3) Load the rubber sample into the non-rotor rheometer cavity.

(4) Start the test; the swing mechanism will apply torque to the sample.

(5) Monitor the displayed data: scorch time, positive cure time, vulcanization index, and maximum/minimum torque.

(6) Stop the test after the set time, remove the sample, and record the results.

Maintenance Information

(1) Keep the instrument clean; remove rubber residues after each test.

(2) Periodically inspect the swing mechanism and torque sensor for wear or damage.

(3) Check temperature calibration regularly to ensure accurate measurements.

(4) Maintain pneumatic components, ensuring air lines and valves are free of leaks.

(5) Store in a dry, non-corrosive environment when not in use.

Send product request

Other supplier products

| Goggles Puncture Resistance Testing Machine | Applicable standards: GB 811-2010 ECE R22.05 EN1077 Purpose It is to make a certain weight of sharp objects fall from the height specified i... | |

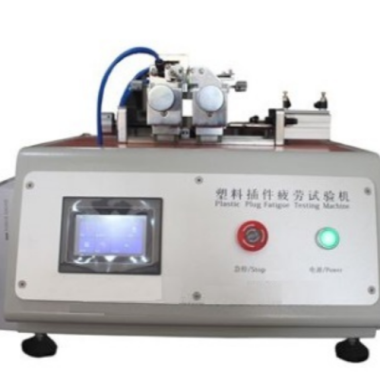

| Bag Plastic Buckle Durability Tester | It is mainly used to test the service life of plastic plug-ins in luggage accessories. Applications This machine simulates the use of plastic cla... | |

| Plastic Pipe Hydrostatic Pressure Burst Tester | The Plastic Pipe Hydrostatic Pressure Burst Tester utilizes an international airless pressure control system. Its core is a dual-CPU control system... | |

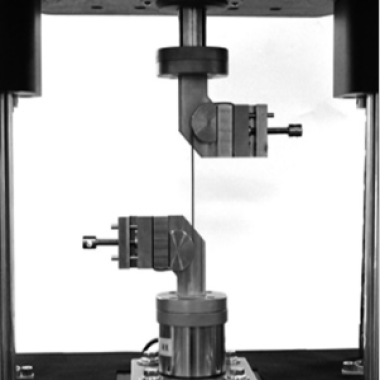

| Metallic Cables and Wire Ropes Mechanical Property Test device | Standard YY/T 0812-2010 (China): Specifies mechanical testing protocols for metal cables/cables used in fracture fixation, including fatigue stren... | |

| Flooring VOC Emission Testing Chamber | Standard ISO 16000-9(Indoor Air - Determination of Volatile Organic Compounds) ASTM D5116(Standard Guide for Small-Scale Environmental Chamber ... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | Seller: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | Seller: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | Seller: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | Seller: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | Seller: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |