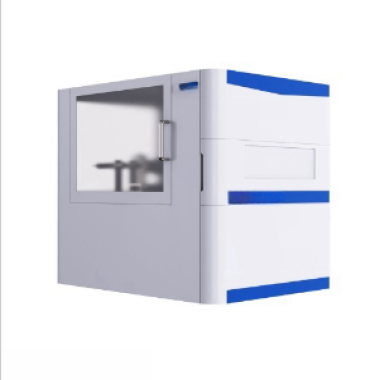

Sauce Packet Pressure Testing Instrument

The pressure resistance tester for sauce packets is a device specifically designed to test the pressure - resistance performance of soft packaging materials such as sauce packets.

Applications

The main purpose of the pressure resistance tester for sauce packets is to evaluate the ability of soft packaging materials like sauce packets to withstand pressure during transportation, storage, and use. By simulating the pressure conditions in the actual environment, the tester can detect whether the sauce packets will burst or leak under pressure, thus ensuring the safety and integrity of the products. This is of great significance to the food industry, as a damaged sauce packet may lead to product contamination, spoilage, or waste, which in turn affects consumers' purchase intention and brand reputation.

Standards

The design and manufacture of the pressure resistance tester for sauce packets usually comply with a series of national and international standards to ensure the accuracy and reliability of test results. These standards may include, but are not limited to:

- Relevant packaging pressure - resistance strength test standards such as GB/T 10004. These standards specify the test methods for the pressure - resistance performance of packaging materials, specimen preparation, test conditions, etc.

- Specific food packaging safety standards, such as the safety standards for food - contact materials, to ensure that the products will not be contaminated or endangered during the testing process.

Features

1. Multi-station synchronous testing: Standard configuration includes a 6-station testing station, capable of testing 6 samples at a time. Customization with additional stations is supported to meet the sampling inspection needs of large-scale production scenarios. A condiment company reported that after using this instrument, the testing time for a single batch was reduced from 2 hours to 20 minutes, a 6-fold increase in efficiency.

2. High-precision sensor system: Employs a 0.1-level precision sensor, supporting multi-range switching (e.g., 0-500N, 0-1000N), accurately capturing minute pressure fluctuations. For example, when testing 0.1mm thick aluminum foil composite film, the instrument can still distinguish a frictional force difference of 0.01N.

3. Intelligent operation and data management: The 7-inch touchscreen supports four-level access control to prevent accidental operation; test data is automatically stored and tamper-proof; a built-in micro-printer can generate reports with one click, complying with GMP and FDA regulations. Optional computer communication software enables data traceability, audit trails, and electronic signature functions.

4. Full-scenario adaptability: Supports pressure testing (simulating stacking pressure) and burst strength testing (determining ultimate pressure resistance), covering the entire life cycle of sauce packets from production to consumption.

Technical Parameters

| Technical Parameter | Specification |

|---|---|

| Test Pressure Range | Usually adjustable within a certain range, such as from 0.1 MPa to 0.7 MPa (equivalent to a pressure of 1 - 50kg) to adapt to different sauce packets and test requirements. |

| Test Time | Can be set according to actual needs, usually with a wide adjustment range, such as from 1 second to hundreds of thousands of seconds. |

| Specimen Size | Generally suitable for specimens of certain sizes, and the specific size range may vary depending on the device model. In actual testing, appropriate cutting or adjustment is required according to the size and shape of the sauce packets. |

| Control System | Modern pressure resistance testers for sauce packets usually adopt advanced control systems, such as micro-computer control or PLC control, to achieve automated operation and precise control. These systems usually have a user-friendly interface and easy-to-operate functions, such as pressure adjustment and data recording. |

| Data Recording and Analysis | Usually equipped with a data recording system and analysis software, which can automatically record data such as pressure changes and specimen deformation during the test and generate detailed test reports. This data can be used for subsequent product quality analysis and improvement. |

| Safety Devices | Usually equipped with various safety protection devices, such as emergency stop buttons and overload protection. These devices can quickly cut off the power supply or stop the test in case of an emergency to prevent equipment damage or personal injury. |

Accessoriess

1. Multi-size sample clamps: Adaptable to sauce packets of different sizes and shapes, ensuring stable sample fixation during testing;

2. Spare pressure sensor: Used for replacement in case of sensor failure, ensuring the accuracy of pressure test data;

3. Calibration standard weights: Auxiliary equipment for periodic calibration of pressure parameters to maintain test accuracy;

4. Data transmission cable: Connects the instrument to a computer for exporting and storing test data;

5. Sample protective pad: Placed between the sample and the clamp to prevent scratches on the surface of the sauce packet during testing;

6. Spare emergency stop button: A spare part of the emergency protection device, improving equipment safety.

Test Procedures

1. Sample Preparation

Prepare the sauce packet sample according to the specified size and shape, ensuring the sample surface is flat and undamaged.

2. Instrument Settings

Set the test parameters of the pressure resistance tester according to the test requirements, such as test speed and test pressure.

3. Test Procedure

Place the sample on the test platform and start the instrument. During the test, the instrument will gradually increase the pressure until the sauce packet ruptures or reaches the set maximum pressure value. The instrument will automatically record and calculate the pressure resistance of the sauce packet.

4. Data Recording

After the test is completed, record and save the pressure resistance value for subsequent analysis and comparison.

Send product request

Other supplier products

| Cylindrical Battery In-Situ Volume Swelling Testing System | Standard UL 1642: Standard for Lithium Batteries IEC 62660-2: Secondary Lithium-Ion Cells – Part 2: Reliability and Abuse Testing ASTM E83... | |

| Timken Test Machine | The extreme pressure friction testing machine mainly consists of a main frame, a spindle transmission system, a test force loading mechanism, a lub... | |

| Demesia Zigzag Tester | The Demesia Zigzag Tester is a professional device used to test the flexural resistance of materials such as rubber, leather, synthetic leather, an... | |

| Shirley Moisture Permeability Tester | Introduction Shirley moisture permeability tester is used to detect water vapor permeability of textiles and textile composites, especially spor... | |

| Particle Strength Tester | Standard ASTM D4179: Standard Test Method for Single-Pellet Pressure Resistance of Catalysts and Catalyst Carriers ASTM D6175: Standard Test Me... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | Seller: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | Seller: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | Seller: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | Seller: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | Seller: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |