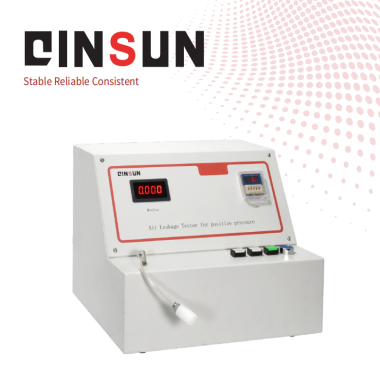

Infusion Apparatus Leakage Positive Pressure Tester

The M102 Infusion Apparatus Leakage Positive Pressure Tester is designed to evaluate the airtightness and sealing performance of medical injection syringes and infusion apparatus. It provides precise measurement of positive pressure integrity, ensuring that medical devices meet required safety standards. This instrument is widely used in laboratories, production quality control, and third-party certification testing.

Application

M102 Infusion apparatus leakage positive pressure tester, Itis suitable for the measurement of positive pressure airtight of medical infusion apparatus, blood transfusion devices, infusion needles, anesthesia bag filters, pipelines, conduits, quick joints, and etc. It can accurately measure whether the sealing performance of injection syringe meets the specified requirements.

It is applicable to the performance verification of new products, quality control of the production department, and the of material properties for the third-party testing organization, the product performance verification laboratory, and the quality and technical supervisiondepartment, etc.

The M102 tester is suitable for testing the positive pressure airtightness of medical devices in the following industries and products:

(1) Medical Devices: injection syringes, infusion sets, anesthesia bag filters — verification of sealing integrity under positive pressure

(2) Blood Transfusion Equipment: transfusion devices, infusion needles — assessment of airtightness to prevent leakage

(3) Pipelines and Conduits: medical tubing, quick joints, and connectors — evaluation of fluid-tight connections

(4) Research and Development: new infusion device prototypes, design optimization for airtight performance

(5) Quality Control Laboratories: production inspection of medical infusion devices to ensure compliance with standards

(6) Certification and Regulatory Testing: third-party laboratories performing performance verification for national and international medical device standards

Standards

The instrument complies with the following standards, including relevant international regulations:

(1) GB 8368-2005 – Disposable Infusion Sets for Single Use — Gravity Infusion Type, including airtightness requirements

(2) ISO 8536-4:2010 – Infusion equipment for medical use — Part 4: Infusion sets for single use, including leak testing methods

(3) ISO 13485:2016 – Medical devices — Quality management systems — Requirements for regulatory purposes (applies to testing and QC of infusion devices)

(4) ASTM F2392-04 – Standard Guide for Leak Testing of Medical Fluid Delivery Devices

Features

(1) Touch-tone control panel with LED digital display for easy operation

(2) Adjustable test pressure range: 0–100 kPa, with ≤ ±2.5% reading error

(3) Flexible test time setting (1–16 s) to meet various requirements

(4) Compact and portable design, suitable for laboratory or production line installation

(5) Automatic operation mode reduces manual intervention

(6) Accurate measurement ensures compliance with medical device safety standards

Technical Parameters

| Item | Specification |

|---|---|

| Control Mode | Automatic |

| Test Pressure Range | 0–100 kPa |

| Pressure Accuracy | ±0.5 kPa |

| Test Time | 1–16 s (adjustable) |

| Weight | 30 kg |

| Power Supply | AC 220 V, 50 Hz |

| Appearance Size | 40 cm × 45 cm × 45 cm |

Accessories

(1) Standard air source connector

(2) Sample fixture for injection syringes and infusion devices

(3) Power cable

(4) Operation manual

(5) Calibration certificate

Operating instructions

1. Turn on the power and turn on the power.

2. Click "next" and enter "main menu". There are four options of "setting", "test", "measurement" and "air release".

3. Click "setting", set the "stress" can be performed at this time, set the "time", "" date and time setting, just enter thecorresponding project selection and vessels of the specifications of the corresponding parameters can be confirmed to betested.

4. Click "set pressure" and click the corresponding number of test pressure to "confirm". (unit: Kpa. "Confirm" and return toset parameters.

5. Click "set time", and then click the corresponding number for the test to "confirm". Unit: seconds. "Confirm" and returnto set parameters.

6. Click "date & time". After clicking "date", enter the date of the test day to be confirmed. (the format is:year/month/day, change of time is similar to change of date. (" confirm "and return to the main menu.)

7. After clicking "measurement", first connect the standard air source, and then measure whether the internal data isstandard. This step is not required for normal operation. This option is used for metering authentication.

8. Click "release", i.e. the internal test data pressure value is clear.

9. See the "main menu" shown in the content and the vessels being measured parameters are set by matching, can click on the"test", after the test according to test results, a visual check to see if the set with the test values of qualified, clickon the "qualified" or "unqualified" after the "print". "Return" returns to the main menu.

Maintenance Information

(1) Keep the instrument clean and dry after each test

(2) Inspect connectors, sample holders, and air supply lines for wear or leaks

(3) Calibrate pressure sensors regularly to maintain accuracy

(4) Avoid excessive force or impact on the instrument to prevent damage

(5) Store in a safe, ventilated environment

(6) Maintain operation and calibration logs for regulatory compliance

Send product request

Other supplier products

| Solid electrolyte analysis system | The Solid Electrolyte Analysis System is a precision testing platform designed to evaluate the ionic conductivity, electrochemical impedance, and i... | |

| Medical injection needle puncture force tester | The Medical Injection Needle Puncture Force Tester is a precision instrument designed to evaluate the puncture performance of medical needles. It s... | |

| Contact heating and cooling test device | The sensation of coldness or warmth when skin touches a fabric is referred to as the "coldness and warmth feeling." The feeling of coldness or warm... | |

| Solar Climatic Test Chamber | Features and Benefits 1. Fully Compliant with IEC 61215 Specifically designed for the UV preconditioning test in PV module qualification. Ensures y... | |

| Thermal - Cold Cycle Testing Machine | The Thermal-Cold Cycle Testing Machine is a professional equipment used for high and low-temperature reliability testing. It is primarily used in f... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | Seller: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | Seller: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | Seller: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | Seller: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | Seller: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |