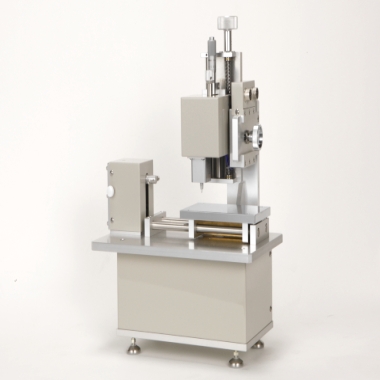

Friction and wear testing machine

It can perform flat grinding, curved grinding, edge grinding, folded edge grinding, and abrasion resistance tests such as anti-frosting, edge sealing, and pilling. The tested samples can be in a dry state or immersed in water, oil, or other liquids. It can be used for woven fabrics, knitted fabrics, coated fabrics, pile fabrics, socks, felt, non-woven fabrics, deep-pile fabrics, yarns, threads, plastic films, rubber, leather, paper, and many other materials.

Application

Petrochemical: Used to assess the long-term wear resistance of lubricating oil and grease, and to develop a variety of high-grade series of hydraulic oil, internal combustion engine oil, gear oil and other products.

Materials science: Helps researchers understand the friction and wear properties of emerging materials, providing important data support for the design and optimization of new materials.

Universities and institutes: as an important tool for teaching and research, it is used for research and exploration in the field of tribology.

Industrial field: such as subway, automobile, train, wind power, ship, construction machinery, etc., used to evaluate the friction and wear performance of various parts.

Standards

ASTM G99-04:Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus

ASTM G77-16:Standard Test Method for Ranking Resistance of Materials to Sliding Wear Using Block-on-Ring Wear Test

ISO 9352:1995:Plastics - Determination of resistance to wear by abrasive wheels

GB/T 12444-2006:Metallic materials - Wear test method - Block-on-ring sliding wear test

GB/T 1865-2009:Paints and varnishes - Artificial weathering and exposure to artificial radiation - Exposure to filtered xenon-arc radiation

Features

1. Equipped with various accessories to meet different standard requirements, offering multiple functions and a wide range of applications;

2. Equipped with both flat and curved abrasion testing heads;

3. Equipped with a digital timer and an LCD display timer;

4. Equipped with one electronic touch rubber diaphragm and one non-electronic touch rubber diaphragm;

5. Equipped with a reciprocating worktable and an improved sample box stretching device;

6. Equipped with a set of pressure weights and a set of tension weights;

7. Equipped with a built-in air compression system;

8. Equipped with perforated and non-perforated sandpaper, and 50 yards of standard ribbon;

9. Equipped with standard fabric, calibration and testing knives.

Parameters

| Feature/Specification | Details |

|---|---|

| Working Range of Test Force | 10 - 1000 N, stepless adjustable |

| Relative Error of Test Force | ±1% |

| Measuring Range of Friction Torque | 0 - 2500 N·mm |

| Relative Error of Friction Torque | ±2% |

| Spindle Speed Range | 1 - 2000 r/min |

| Maximum Output Torque of Main Motor | 5 N·m |

| Test Medium | Oil, Water, Mud, Abrasive, etc. |

| Temperature Control Range | Room Temperature - 260°C |

| Maximum Distance between Main Shaft and Lower Sub-disk | >75 mm |

| Test Time Control Range | 1 s - 999999 min |

Accessoriess

Friction pairs: such as four-ball, pin-on-disk, thrust ring, and ring-block configurations, used to simulate different friction and wear conditions.

Loading device: such as spring-type force application systems and lever loading systems, used to apply test force to the friction pair.

Driving system: including motors and reduction gears, used to drive the movement of the friction pair.

Sensors: such as test force sensors, friction force sensors, and temperature sensors, used to measure key parameters during the test process.

Oil bath and heater: used to simulate wet friction environments; the oil bath can hold lubricating oil or other liquid media, and the heater can control the test temperature.

Other accessories: such as chucks, tie rods, screws, springs, and nuts, used for the assembly and debugging of the testing machine.

Test Procedures

Preparation:

Determine the type of friction pair for the test and machine the samples according to the drawings.

Clean the samples, lower disc, and fixtures to ensure they are free of impurities.

Powering on:

Turn on the testing machine's power supply, start the control computer, and preheat the equipment for 10 minutes.

Sample installation:

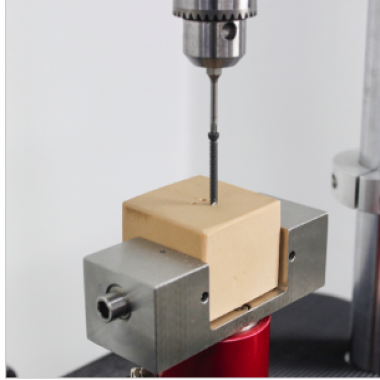

Install the prepared samples into the corresponding fixtures, ensuring they are securely clamped.

If conducting a heating test, connect the temperature controller and temperature sensor.

Parameter setting:

According to the test requirements, set parameters such as load and speed, ensuring they meet the test standards.

Starting the test:

Press the start button to begin the test; the time and cycle count will begin.

By following these steps, the friction and wear testing machine can be used correctly, thus obtaining accurate test

Send product request

Other supplier products

| Enamel Boiling Water Resistance Tester | The Enamel Boiling Water Resistance Tester is designed to evaluate the chemical attack resistance of enamel coatings under boiling water conditions... | |

| Rubber hose outer coating wear test chamber | Product Introduction: Rubber hose outer coating Wear testing machine for hydraulic hoses and other similar types of hoses with fabric or steel wir... | |

| Metal Bone Screws Torque Tester | Standard YY/T 1506. ASTM F543: The standard specifies the torque required to measure the torque required to screw a metallic bone grafting screw ... | |

| Electric pencil hardness test machine | Product Introduction: This machine is suitable for all kinds of finished product spray hardness test, such as: mobile shell, laptop computer shel... | |

| Puncture Strength Tester STD - NDG5 | Compliance Standards ASTM D638 (Plastics Tensile Properties) ISO 13934-1 (Textile Tensile Strength) SAE J2749 (Automotive Composite Testing) JI... |

Same products

| Gas Oxidizing Property Tester | Seller: Standard International Group (HK) Limited | Product Description Conforms to ISO 10156-2010 “Gases and Gas Mixtures Selection of Cylind... | |

| Battery Powder Compaction Density Measurement System | Seller: Standard International Group (HK) Limited | The Battery Powder Compaction Density Measurement System is a precision testing system designed... | |

| Battery Powder resistance tester | Seller: Standard International Group (HK) Limited | The Powder Resistivity Meter is a precision testing system designed to measure electrical resisti... | |

| KES-SESRU surface roughness/friction tester | Seller: Standard International Group (HK) Limited | TheRoughness/Friction Tester analyzes hand movements-particularly, strokes-performed by artisans ... | |

| Air Permeability Tester STD- F8 | Seller: Standard International Group (HK) Limited | The Air Permeability Tester is designed to quickly and accurately measure the breathability and p... |