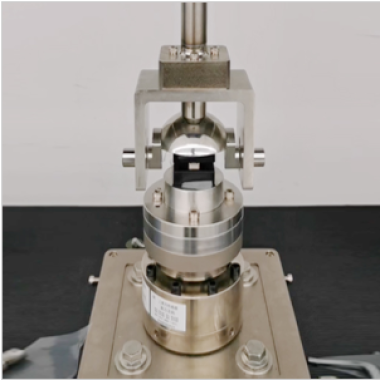

Hot Tack Tester / Heat Seal Tester

The Hot Tack Tester/Heat Seal Tester is specifically designed for testing the heat-adhesion and heat-sealing properties of packaging materials such as plastic films and composite films. It is also suitable for testing the peeling and tearing properties of soft materials such as adhesives, adhesive tapes, self-adhesive labels, adhesive composites, composite films, plastic films, and paper.

Applications

The hot - tack tensile tester is an instrument specifically designed to test the hot - tacking and heat - sealing properties of packaging materials. Its main uses include, but are not limited to: - Evaluating the Heat - Sealing Performance of Packaging Materials: By simulating the heat - sealing conditions of packaging production lines, it tests the strength of materials after heat - sealing, ensuring that packaging materials can maintain their integrity during transportation and storage. - Quality Control: During the production of packaging materials, regular testing with a hot - tack tensile tester can promptly identify production issues, ensuring stable and reliable product quality. - Material R & D: In the process of developing new materials, the hot - tack tensile tester can be used to evaluate the impact of different formulations and processes on the heat - sealing performance of materials, providing a basis for material optimization. - Applications in Multiple Fields: In addition to packaging materials, the hot - tack tensile tester can also be used to test the peeling and breaking properties of soft materials such as adhesives, adhesive tapes, self - adhesive labels, and paper, providing technical support for the application of these materials.

Standards

GB/T 34445-2017:Safety requirements for baby walkers straps

ASTM F2029:Standard Specification for Guidewires for Medical Applications

Features

1. Four testing functions—heat tack, heat seal, peel, and tensile strength—provide users with more combinations of testing conditions.

2. Digital P.I.D temperature control technology not only quickly reaches the set temperature but also effectively avoids temperature fluctuations.

3. Four force ranges and six testing speeds meet diverse user testing needs. The system is equipped with automatic zeroing, fault indication, overload protection, and travel protection to ensure user safety.

4. Manual and foot pedal start modes, along with a burn-proof safety design, effectively ensure user convenience and safety.

5. Microcomputer control, LCD display, PVC operation panel, and menu-driven interface facilitate quick operation and data viewing.

6. RS232 data transmission interface allows for easy import and export of test data. Supports the Lystem™ laboratory data sharing system for unified management of test results and reports.

Technical Parameters

| Technical Parameter | Specification |

|---|---|

| Heat-Sealing Pressure | Adjustable from 0.05 MPa to 0.7 MPa, used to simulate different heat-sealing conditions. |

| Heat-Sealing Time | Adjustable from 0.1s to 999.9s, ensuring that the heat-sealing process reaches a stable state. |

| Hot-Tack Time | Adjustable from 0.1s to 999.9s, used to evaluate the performance of materials during the hot-tacking process. |

| Temperature Control | Using digital P.I.D temperature-control technology, it can quickly reach the preset temperature and maintain the temperature stable. |

| Force Range | Multiple ranges are available, such as 0 - 200N (some devices may have a larger range). |

| Accuracy | Generally level 1 or higher, ensuring the accuracy of measurement results. |

Accessoriess

Standard Configuration: Main unit, pneumatic clamp, foot switch, Φ6 mm polyurethane hose (2m)

Optional Accessories: Professional software, communication cable, extended polyurethane hose, air compressor.

Note: The compressed air source interface of this machine is a Φ6 mm polyurethane hose; the air source and air source adapter are to be provided by the user; if the software is purchased separately, the computer is to be provided by the user.

Test Procedures

1.Device Preparation

Check the integrity of components (heat-sealing module, tensile sensor, clamps) and connect the power supply (110-240VAC, 50-60Hz).

Power on the device, activate the digital P.I.D temperature control system, and preheat to the preset temperature (wait for temperature stability).

2.Sample Preparation

Cut the packaging material (e.g., plastic film, composite packaging material) into standard-sized specimens (ensure surface is clean, free of impurities or damage).

3.Parameter Setting

Operate the 160×128 dot graphic LCD (with alphanumeric keypad) to set test parameters:

Heat-sealing pressure: 0.05–0.7MPa (adjust per material type).

Heat-sealing time: 0.1–999.9s (match production line conditions).

Hot-tack time: 0.1–999.9s (for hot-tack performance evaluation).

Force range: Select appropriate range (e.g., 0–200N) based on material stiffness.

4.Sample Installation

Fix the prepared specimen in the heat-sealing clamp (ensure alignment to avoid offset) and secure the other end in the tensile test clamp.

5.Test Execution

Start the heat-sealing process: The device completes heat-sealing under the set pressure/time/temperature.

Trigger the hot-tack tensile test: The instrument automatically applies tensile force to the freshly sealed specimen and records real-time data (e.g., hot-tack strength, heat-seal integrity).

6.Data Acquisition & Analysis

The built-in data system automatically collects test data, generates force-time curves, and calculates key indicators (e.g., heat-seal strength, hot-tack force).

7.Post-Test Operation

Remove the tested specimen, clean the clamps/heat-sealing module to avoid residue buildup.

Save the test report (including parameters, curves, and results) via the device interface.

Power off the device after cooling.

Send product request

Other supplier products

| STD IPX7 Machine Waterproof Test Chamber | Product Introduction Test the product waterproof performance in the soaking environment (water depth 1 meters). Through the test ,check whether t... | |

| Thermal Radiation Flooring Combustion Tester | Product Standards ISO 9239 - 1: Reaction to fire tests for floor coverings - Part 1: Determination of the burning behaviour of floor coverings usi... | |

| Compression Fatigue Testing Machine | Standard YY/T 0959-2014 (China): Specifies compression fatigue testing protocols for intervertebral fusion devices, including load ratios, frequen... | |

| Smoke Density Chamber, ISO 5659,Smoke density testing equipment | Introduction The main principle is to measure smoke density in a particular space, cable or material produced under specific conditions of combust... | |

| Infusion device Leakage negative pressure tester | The Infusion Device Leakage Negative Pressure Tester is designed to evaluate the airtightness of syringes, infusion sets, and related medical devic... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | Seller: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | Seller: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | Seller: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | Seller: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | Seller: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |