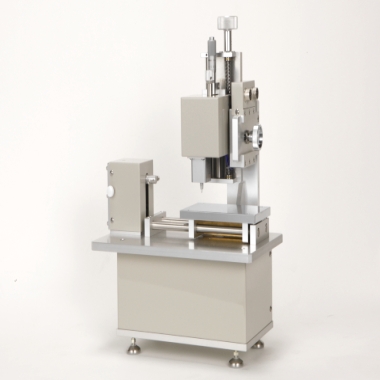

Automatic Cap Torque Tester

A Bottle Cap Torque Tester is a specialized device used to measure the torque applied to bottle caps during sealing or opening processes. Its primary purpose is to ensure that bottle caps are properly tightened to prevent leakage or contamination of the contents within the bottle. Conversely, it can also be used to measure the torque required to open bottle caps, which is useful for assessing consumer usability and product quality.

Applications

Basic Applications:

Bottle Packages

Application and removal torque test of the bottle caps for bottled packages for food, pharmaceuticals, e.g. beverage or tablet bottles

Flexible Tube Packages

Application and removal torque test of flexible tube packages for food, pharmaceuticals and cosmetics, e.g. eye-drop, hand cream and shoe polish

Extended Applications:

Screws

Application and removal torque test of the screws

Vacuum Flasks and Vacuum Cups

Application and removal torque test of the caps of vacuum flasks and vacuum cups

Standards

ASTM D2063:Standard Test Method for Seal Strength of Flexible Barrier Materials

ASTM D3198:Standard Test Method for Blocking Load of Flexible Thermoplastic Films and Sheeting

ASTM D3474:Standard Specification for Pressure-Sensitive Tape for Packaging, Box Sealing

BB/T 0025:Biaxially Oriented Polypropylene Pearlescent Film

BB/T 0034:Biaxially Oriented Polypropylene Film for Packaging

GB/T 17876:Packaging Containers - Plastic Child-Resistant Caps and Closures

Technical Parameters

| Items | Specifications |

| Load Cell Capacity | 5 Nm (Standard) 20 Nm, 40Nm (Optional) |

| Accuracy | 0.5% FS |

| Resolution | 0.001 Nm |

| Twisting Speed | 10 r/min (adjustable) |

| Clamp Force | Adjustable according to the sample |

| Body Clamp Range | Φ5 mm ~Φ190 mm (Diameter) Φ10 mm ~Φ120 mm (Diameter) (customizable) |

| Data Numbers | 1 ~ 999 (No up limits on professional software,and multiple units available.) |

| Gas Pressure | 0.4 MPa ~ 0.6 MPa (outside of supply scope) |

| Port Size | Ф6 mm PU Tubing |

| Power Supply | AC 100-240V 50/60Hz (can be changed to local requirement) |

| Instrument Dimension | 350 mm (W) x 620 mm (D) x 770 mm (H) |

| Net Weight | 48 kg |

Features

Moveable 1.25″ (31 mm) length posts accommodate a wide range of sample shapes and sizes

Available extended post lengths and other gripping options

USB, RS-232. Mitutoyo, and analog outputs

Automatic output, data storage, and zeroing upon bottle cap removal helps automate testing processes

First / second peak detection for slip and breakaway torques in tamper evident closures

1.000-point data memory with statistics and outputs

Password protection prevents unauthorized changes

Programmable set point indicators and outputs for pass/ fail determination

High-speed 7.000 Hz sampling rate accurately captures peak torque values

Configurable audio alarms and key tones

5 selectable units of measurement

Lite data collection software included

Accessoriess

Standard configuration: Main unit, clamping rods (4), clamping blocks (1 pair), calibration components (excluding calibration weights), Φ4mm polyurethane tubing (2m)

Optional: Mini printer, professional software, air compressor, GMP computer system requirements, DataShield™ (Note 3)

Remarks: The air supply interface of this unit is a Φ4mm polyurethane tubing; the air supply is to be provided by the user.

Test Procedures

1. Equipment Preparation: Connect the power and air supply, turn on the machine, and preheat the equipment.

2. Sample Fitting: Adjust the clamps (bottle body clamp/cap clamp) to the corresponding range according to the bottle body and cap dimensions.

3. Sample Clamping: Fix the sample to be tested (bottle + cap) in the clamp and tighten it using the pneumatic device.

4. Parameter Setting: Select the corresponding torque range and set the test mode (tightening/opening torque).

5. Start Testing: Run the automatic testing program; the equipment completes torque detection and records the data.

6. Result Viewing: Export the test data and view the torque results through the statistical function.

Send product request

Other supplier products

| Medical Face Mask Synthetic Blood Penetration Tester | Applicable Standards: GB 19083-2010 YY/T 0691-2008 YY 0469-2011 ISO 22609 ASTM F1862-07 Features: 1. Mask fixture is metal human head ... | |

| Falling Sand Abrasion Test machine | Applicable Standard JG/T 133-2000 ASTM D968-83 ASTMD333 ASTMD1395 ASTMD2205 Main Purposes It is mainly used to test the abrasion - resistanc... | |

| Helmet Strap Tensile Tester | The helmet strap tensile testing machine is designed to simulate tensile, impact, and durability loads encountered in actual use, accurately evalua... | |

| Finished shoe bending tester丨Finished shoe bending test mechine | Product Introduction: Finished shoes bending testing machine Finished shoes bending testing machine Test shoes, casual shoes, work shoes and other... | |

| Konan Tester | Product Description Conforms to the UN Recommendations on the Transport of Dangerous Goods - Manual of Tests and Criteria 11.5.1 Test 1(b): Kernan... |

Same products

| Gas Oxidizing Property Tester | Seller: Standard International Group (HK) Limited | Product Description Conforms to ISO 10156-2010 “Gases and Gas Mixtures Selection of Cylind... | |

| Battery Powder Compaction Density Measurement System | Seller: Standard International Group (HK) Limited | The Battery Powder Compaction Density Measurement System is a precision testing system designed... | |

| Battery Powder resistance tester | Seller: Standard International Group (HK) Limited | The Powder Resistivity Meter is a precision testing system designed to measure electrical resisti... | |

| KES-SESRU surface roughness/friction tester | Seller: Standard International Group (HK) Limited | TheRoughness/Friction Tester analyzes hand movements-particularly, strokes-performed by artisans ... | |

| Air Permeability Tester STD- F8 | Seller: Standard International Group (HK) Limited | The Air Permeability Tester is designed to quickly and accurately measure the breathability and p... |