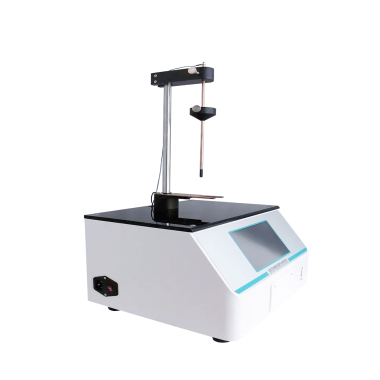

Aluminum Ointment Tube Toughness Tester

The ductility tester for aluminum tubes is a device specifically used to detect the ductility indicators of packaging materials such as aluminum soft tubes.

Applications

The main purpose of the ductility tester for aluminum tubes is to evaluate the deformation and recovery ability, that is, the ductility, of packaging materials such as aluminum soft tubes under external forces. Through testing, we can understand the performance of aluminum tubes when subjected to external forces such as extrusion and bending during transportation, storage, and use, thereby ensuring the safety and integrity of products. This is particularly important for industries such as medicine, cosmetics, glue, and toothpaste. As the main packaging material for products in these industries, the ductility of aluminum soft tubes directly affects the product's user experience and market competitiveness.

Standards

The design and manufacture of the ductility tester for aluminum tubes usually comply with a series of national and international standards to ensure the accuracy and reliability of test results. Among them, common standards include YBB00162002 - 2015 Aluminum Pharmaceutical Soft Tubes, etc. These standards specify in detail the test methods for the ductility of aluminum tubes, specimen preparation, test conditions, etc., providing a unified standard for the use of the tester.

Features

Designed strictly according to national or industry standards, it meets standard testing requirements, ensuring compliant test results and accommodating all hose specifications.

Utilizing a high-precision measurement system, it accurately reads the gate's scale markings, thus quantifying the aluminum tube's toughness.

Made of 304 stainless steel with electroplating, it boasts a beautiful appearance and high material strength.

Technical Parameters

| Technical Parameter | Specification |

|---|---|

| Measurement Range | Usually applicable to aluminum soft tubes with a diameter between 10 and 45mm (some devices cover 8-45mm) and a certain tube length; covers most common aluminum tube specifications for wide applicability. |

| Gate Plate Weight | Precisely controlled within 70g±1g (a key pressure-applying component, ensuring testing consistency and accuracy). |

| Testing Accuracy | Equipped with a high-precision measurement system (e.g., current measurement accuracy reaches ±0.1mA) to quantify aluminum tube deformation under external forces (specific accuracy varies by device). |

| Automation Level | Adopts automatic and intelligent technologies; features one-click operation, automatic timing, and data recording to reduce operator burden and improve test accuracy/traceability. |

| Appearance Dimensions and Weight | Usually compact and portable (varies by model/brand), enabling use in different production sites and laboratories for flexible, convenient testing. |

| Working Environment | Requires a specific environment: working temperature 23℃±2℃, relative humidity ≤80% (no condensation); ensures equipment stability and test result accuracy. |

Accessoriess

Standard configuration: Main unit

Test Procedures

Select a suitable stepped support.

Place the sample onto the mandrel, with the tail end of the tube fitted onto the first-level step corresponding to the aluminum tube's specifications. The mandrel should extend from the nozzle. The aluminum tube should remain perpendicular to the base throughout the test. Place the top pressure plate over the extended mandrel and gently rest it on the top of the nozzle. Apply uniform pressure to the pressure plate and quickly press the aluminum tube downwards. The aluminum tube should exhibit a uniformly folded "accordion" shape. Remove the pressed aluminum tube from the mandrel and stretch it as close to its original length as possible. Cut it longitudinally and observe the surfaces of the inner and outer coatings. There should be no cracks or peeling in the inner and outer coatings.

Send product request

Other supplier products

| Helmet Strap Tensile Tester | The helmet strap tensile testing machine is designed to simulate tensile, impact, and durability loads encountered in actual use, accurately evalua... | |

| Metal ring friction and wear testing device | Evaluate the wear resistance of the material: By simulating the friction process, real-time monitoring of friction, temperature, wear and other pa... | |

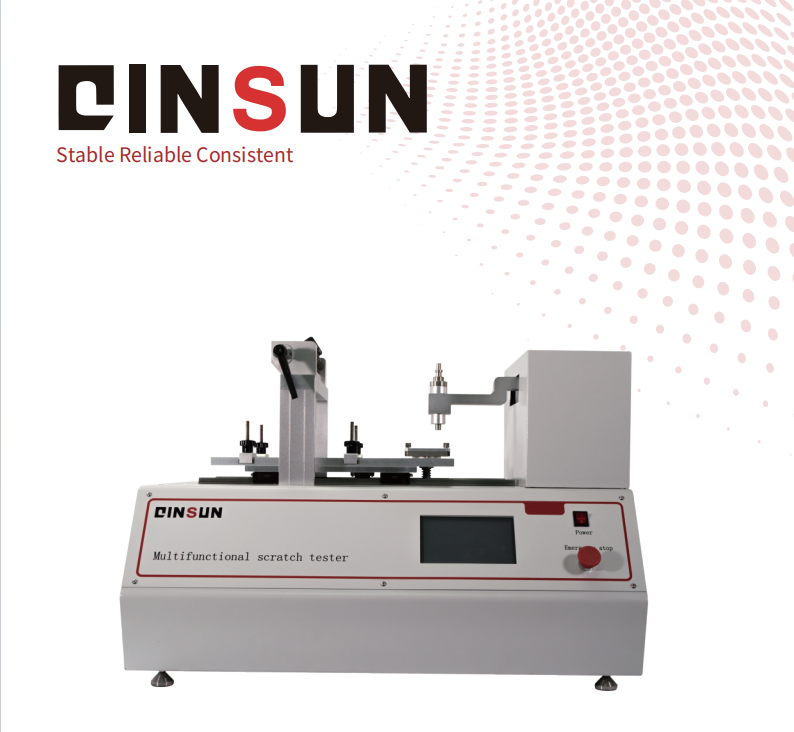

| Multi-function Scratcher | Application It is suitable for testing automotive interior materials, plastics, rubber, leather, coated fabrics, coating materials, composite mate... | |

| Steel wheel wear testing machine | Meet the standard: GB/T3810.7-2016 "Wear resistance test method for unglazed brick" ISO/DIS10545/6-94 "Unglazed brick resistance to deep wear tes... | |

| UV Xenon Arc Weather Testing Chamber | Product introduction This equipment uses xenon arc lamp that can simulate the whole spectrum of sunlight reproduction under different environments... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | Seller: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | Seller: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | Seller: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | Seller: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | Seller: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |