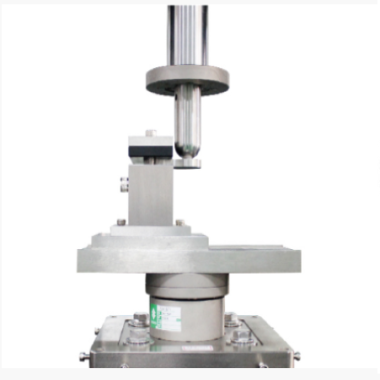

Steel wheel wear testing machine

Meet the standard:

GB/T3810.7-2016 "Wear resistance test method for unglazed brick"

ISO/DIS10545/6-94 "Unglazed brick resistance to deep wear test method"

GB/T12988-1009 "Inorganic floor material resistance test method"

EN 932-5

ISO 565. 3310-1. 3310-2

ASTM E11. 323

BS 410-1. 410-2

Product Introduction:

The cycloidal pinwheel reducer has the advantages of large reduction ratio, compact structure, smooth transmission and adjustable abrasive flow rate, which can effectively save the amount of abrasive. The testing machine through the gear drive deceleration to steel wheel speed 75r/min, gear drive compared with the belt drive deceleration, smooth, no skid phenomenon, steel wheel rotation by the time relay control, the motor to the predetermined time is also transferred to the test requirements of the speed

The motor stops automatically. The testing machine has the characteristics of reasonable design, simple structure, beautiful appearance, easy operation, smooth rotation, automatic shutdown to meet the test requirements, etc., which is mainly suitable for wear resistance test of cement bricks.

Product Advantages:

Provides precise and repeatable wear resistance testing for a range of building materials.

Complies with key international and national standards, including GB/T3810.7. ISO 10545-6. and GB/T12988.

Features a cycloidal pinwheel reducer for smooth transmission, large reduction ratio, and adjustable abrasive flow rate, promoting abrasive saving.

Utilizes a gear drive deceleration system for stable rotation and no skidding, ensuring accurate test conditions.

Offers automatic shutdown based on time relay control, enhancing test efficiency and convenience.

Characterized by reasonable design, simple structure, aesthetic appearance, and ease of operation.

Capable of simulating long-term abrasive wear in a controlled laboratory setting.

Product Features:

Cycloidal Pinwheel Reducer: Provides efficient and stable speed reduction with a large ratio.

Gear Drive Deceleration System: Ensures smooth, non-skid transmission of power to the grinding wheel.

Steel Grinding Wheel: Two types available with specific dimensions (Diameter 200±0.2mm, Thickness 10±0.1mm or 70±0.1mm) and hardness (HB203-245 for the thicker wheel).

Time Relay Control: Precisely controls the rotation duration of the grinding wheel, enabling automatic shutdown.

Abrasive Feeding System: Includes a hopper with a volume greater than 5L and a mechanism for feeding abrasive at an adjustable flow rate.

Sample Loading Mechanism: Designed to securely hold samples of specified dimensions (100mm x 110mm) under defined loads.

Weight Sets: Includes two different weight sets (2.5kg for GB/T3810.7-2006 and 14kg for GB/T12988-91) to apply varying loads according to different standards.

Digital Display: For presetting and displaying test time.

Technical parameters:

Grinding wheel -: Diameter 200+0.2mm, thickness 10+0.1mm,

Grinding wheel 2: Diameter 200+0.2mm, thickness 70+0.1mm, hardness HB203-245

Grinding wheel speed :75+4r/min constant;

Sample size :100mm x 110mm;

Abrasive: Size is IS08486-1986 F80 white melt alumina:

Abrasive feed speed :(100+10)g/100r adjustable flow rate;

Hopper volume: greater than 5L:

Test time: preset, digital display;

Weight -: a mass of 2.5kg(for GB/T3810.7-2006)

Weight two: a mass of 14k(for GB/T12988-91)。

Overall dimensions :6000x580x130mm

Weight: About 150kg

How to operate:

1- The sample to be tested is fixed with the help of fixing apparatus.

In order start using to device, the sample is fixed by placing it in its place via the handle on the device.

2- Before adding abrasive grit, it should noted that the valve under the sand chamber is in the closed position.

3- Abrasive sand is filled into the hopper.

4- To adjust the revolution speed, firstly press to "Set" button and after "PRST" button.

5- Sample is should by push lever up place it in contact with the disc.

6- For Start to test, should press to "Start" button.

7- When the disc begin rotate, slowly open grit valve.

Send product request

Other supplier products

| Photovoltaic module outdoor exposure test system | The Photovoltaic Module Outdoor Exposure Test System is designed to simulate real-world environmental conditions for accelerated aging and performa... | |

| Tibial Tray Fatigue Tester | Standard YY/T 0810 (China): Specifies fatigue testing protocols for tibial trays in total knee arthroplasty, focusing on support and protection of... | |

| Thrust Bearing Rolling Friction and Wear Tester | Applicable Standards: ASTM D3702 ASTM G99 ASTM G77 ISO 18535 Product Advantages: Simulates Real-World Conditions: Allows testing under contro... | |

| Catheter Residual Vacuum Tester | The Catheter Residual Vacuum Tester is a professional device used to detect the residual vacuum in respiratory suction catheters, aiming to ensure ... | |

| DSC Differential Scanning Calorimeter | The Differential Scanning Calorimeter (DSC) measures heat flow to/from a sample (1-10 mg) in a closed crucible within a temperature-controlled furn... |

Same products

| Xenon Test Chamber | Seller: Standard International Group (HK) Limited | Features and Benefits 1.The use of xenon arc lamp as a light source, can simulate the full sunli... | |

| Single Cable Vertical Flame Tester | Seller: Qinsun Instruments Co., LTD | Introduction Single Cable Vertical Flame Tester is used for the vertical flame propagation of a ... | |

| Safety Helmet Flammability Tester | Seller: Qinsun Instruments Co., LTD | Product Introduction: Safety hat flame retardant performance tester for safety hat flame retarda... | |

| Furniture flammability tester | Seller: Qinsun Instruments Co., LTD | Product details Furniture flammability tester is mainly used to test the combustion performance ... | |

| Flame retardant testing machine | Seller: Qinsun Instruments Co., LTD | Feature highlights: Flame Retardant Tester is designed for testing plastic runway surface layers... |