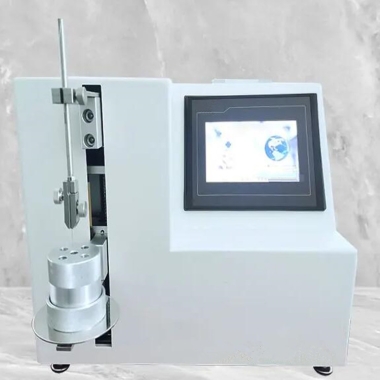

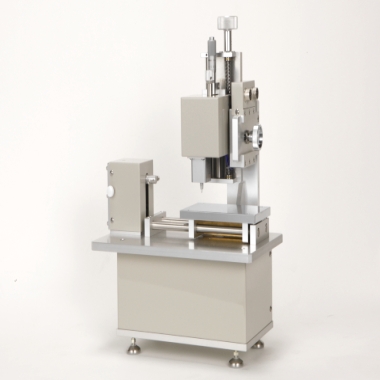

Guide pin anchoring force tester

The Guide Pin Anchoring Force Tester is designed to evaluate the anchoring performance of mammary positioning wires and guide needles. It ensures that the positioning filament remains stable within tissue, preventing displacement or dislodgement prior to surgery. This testing is essential for accurate tumor localization and safe surgical procedures.

Application

This instrument is suitable for a variety of medical and surgical applications, including:

(1) Mammary positioning wires for breast surgery – ensuring stability during preoperative procedures.

(2) Guide needles used in tumor localization – verifying anchoring effectiveness.

(3) Surgical R&D – testing new positioning wire or guide needle designs.

(4) Quality control in manufacturing – confirming the reliability of disposable guide needles and positioning filaments.

(5) Preclinical trials – simulating in-tissue performance of positioning devices.

Standards

The device is designed to meet the following standards:

(1) YY/T 0880-2013: Disposable Breast Positioning Wire and Guide Needle (China)

Optional international reference standards for extended compliance:

(2) ISO 10555-1: Sterile single-use intravascular catheters – General requirements

(3) ASTM F2084: Mechanical testing for medical guidewires

Features

(1) Accurately measures anchoring force to ensure clinical reliability.

(2) High-precision force sensor with hardware and software protection.

(3) Adjustable test speed and distance for flexible simulation.

(4) Built-in printer for immediate recording of test results.

(5) USB connectivity for data storage and export.

(6) Durable fixture made of high-quality 304 stainless steel.

(7) Simple operation with real-time force monitoring.

Parameters

| Parameter | Specification |

|---|---|

| Tensile force range | 0 – 20 N, accuracy ±1%, resolution 0.01 N |

| Test time | 1 – 999 s, error ±0.5 s |

| Test speed | 10 mm/min, 50 mm/min, 100 mm/min |

| Distance adjustment | 10 – 50 mm, adjustable |

| Force sensor | High-precision, with hardware/software protection |

| Fixture | 304 stainless steel |

| Force measuring mechanism | Built-in |

| Printer | On-board micro printer |

| Data storage | USB compatible, export to computer |

| Machine power | 70 W |

| Power supply | AC 90–240 V, 50 Hz |

Accessories

(1) Main test unit – 1 set

(2) USB storage device – 1 set

(3) Micro printer paper – 1 roll

(4) Operation manual – 1 set

(5) Optional fixtures/adapters for different guide needle diameters

Test Procedures

(1) Secure the guide needle or positioning wire into the stainless steel fixture.

(2) Adjust the test distance according to the sample size.

(3) Set the desired test speed and duration.

(4) Start the test; the instrument applies tensile force to the guide needle.

(5) Monitor the anchoring force in real-time.

(6) Test results are automatically recorded via the built-in printer and can be exported via USB.

Maintenance Information

(1) Keep the fixture, sensors, and printer clean and free of debris.

(2) Regularly calibrate the force sensor to ensure measurement accuracy.

(3) Avoid exposure to excessive moisture or vibration.

(4) Inspect mechanical components periodically for wear or loosening.

(5) Follow electrical safety standards during operation.

Send product request

Other supplier products

| Fabric textile 45 degree flammability tester | Applications: 45 degree flammability testeris designed to determine the burning characteristics of textiles. Stainless steel test cabinet with g... | |

| Pressure Transmission Flow Meter Test Instrument | The Pressure Transmission and Flow Tester is widely used in multiple fields and is mainly used to test the pressure transmission and flow performan... | |

| Horizontal Vertical Flame Tester | Introduction Rubber horizontal vertical flame testeris designed to simulate the early firing situation of electronic and electrical products in or... | |

| Helmet Surface Friction Testing Machine | A helmet surface friction testing machine is a device used to test the frictional force between the surface of a helmet and other objects. Its main... | |

| Falling Sand Abrasion Test machine | Applicable Standard JG/T 133-2000 ASTM D968-83 ASTMD333 ASTMD1395 ASTMD2205 Main Purposes It is mainly used to test the abrasion - resistanc... |

Same products

| Gas Oxidizing Property Tester | Seller: Standard International Group (HK) Limited | Product Description Conforms to ISO 10156-2010 “Gases and Gas Mixtures Selection of Cylind... | |

| Battery Powder Compaction Density Measurement System | Seller: Standard International Group (HK) Limited | The Battery Powder Compaction Density Measurement System is a precision testing system designed... | |

| Battery Powder resistance tester | Seller: Standard International Group (HK) Limited | The Powder Resistivity Meter is a precision testing system designed to measure electrical resisti... | |

| KES-SESRU surface roughness/friction tester | Seller: Standard International Group (HK) Limited | TheRoughness/Friction Tester analyzes hand movements-particularly, strokes-performed by artisans ... | |

| Air Permeability Tester STD- F8 | Seller: Standard International Group (HK) Limited | The Air Permeability Tester is designed to quickly and accurately measure the breathability and p... |