Rubber Sleeve Rebound Tester

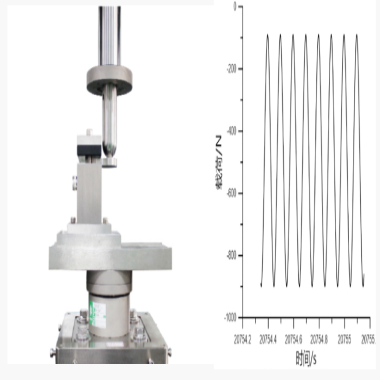

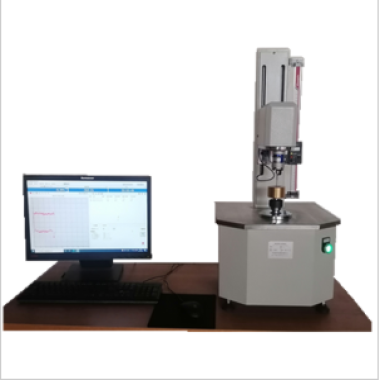

The Rubber Sleeve Rebound Tester is designed to evaluate the resilience and compression performance of collection needle rubber sleeves. It measures the force exerted when the needle tube passes vertically through a die hole, providing quantitative data to ensure product consistency and compliance with medical device standards.

Application

The tester is applicable to a variety of medical and laboratory products, including:

(1) Collection tubes and blood sampling needles – assessing rubber sleeve rebound force to ensure secure sealing and consistent operation.

(2) Pre-filled syringes – verifying the compression and resilience of protective rubber stoppers.

(3) Catheter and infusion system components – evaluating the elasticity and durability of rubber components.

(4) Quality control in production – ensuring each batch meets predefined resilience specifications.

(5) Research and development – optimizing rubber formulations for medical applications.

Standards

The Rubber Sleeve Rebound Tester is designed to comply with the following standards:

(1) YY/T 1618-2018: Collection Needle Rubber Sleeve Resilience Test (China)

(2) DIN 53 512: Testing of Rubber – Rebound Resilience (Germany)

(3) ISO 4662: Rubber, Vulcanized or Thermoplastic – Determination of Rebound Resilience

(4) ASTM D7121: Standard Test Method for Rubber Compression Set

Features

(1) Accurate measurement of rubber sleeve resilience at multiple distances.

(2) Adjustable test speed and pressure for various sample requirements.

(3) Real-time display of test force and calculated results.

(4) Onboard printing for test reports, including average values and deviation.

(5) Supports testing of needles and collection tubes with minimal setup.

(6) Compact design suitable for laboratory and production environments.

Parameters

| Parameter | Specification |

|---|---|

| Pressure test range | 0 – 50 N, error ≤ ±1%, resolution 0.01 N |

| Test time | 1 – 999 s, error ≤ ±0.5 s |

| Test speed | 50 mm/min, 80 mm/min, 100 mm/min, error ≤ ±2% |

| Measuring distance | 0 – 50 mm, error ≤ ±0.1 mm |

| Rebound force range | 0.5 – 1.5 N |

| Printing capability | 8, 10, or 13 test data points, including average and deviation |

| Machine dimensions | Customizable depending on model and fixture |

| Power supply | AC220 V, 50 Hz (standard) |

Accessories

(1) Main test unit – 1 set

(2) Needle clamping fixtures – 1 set

(3) Printer paper roll – 1 piece

(4) Operation manual – 1 set

(5) USB storage (optional)

Test Procedures

(1) Insert the needle at the butt end into the die hole of the clamping fixture, 2 mm above the surface.

(2) Start the test device to compress the rubber sleeve.

(3) Measure the rubber sleeve resilience at distances of 5 mm and 15 mm between the needle tube and the needle base.

(4) The instrument displays and records the rebound force. Each test can print 8, 10, or 13 data points, including average and deviation.

(5) Confirm that the measured resilience falls within the standard range of 0.5 N ≤ resilience ≤ 1.5 N.

Maintenance Information

(1) Regularly clean the clamping fixtures and die holes to prevent debris buildup.

(2) Calibrate the force sensor periodically to maintain accuracy.

(3) Avoid prolonged exposure to high humidity or corrosive environments.

(4) Inspect electrical connections and printer components for wear or damage.

(5) Follow standard laboratory safety procedures when operating the device.

Send product request

Other supplier products

| Femoral Stem Neck Prostheses Fatigue Testing Machine | Standard YY/T 0809.6 (China): Specifies neck fatigue testing for femoral stems in partial/total hip arthroplasty. ISO 7206-6 (International): Def... | |

| Flip Phone Durability Tester | The Flip Phone Durability Tester is a specialized testing machine designed to evaluate the fatigue life and mechanical reliability of clamshell and... | |

| Face Mask Tensile Tester | The Face Mask Tensile Tester is designed to measure tensile strength, elongation at break, and related mechanical properties of various textiles an... | |

| SUGA S80 Carbon Arc Weathering Tester | Applicable Standards The SUGA S80 adheres to globally recognized standards, including: ISO, AATCC, ASTM(e.g., ASTM G152. ASTM D822 for coatings) ... | |

| Bearing Friction Torque Measuring Instrument | Bearing friction torque is an important factor affecting bearing noise, vibration, and lifespan, and is a key indicator for measuring the dynamic p... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | Seller: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | Seller: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | Seller: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | Seller: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | Seller: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |