Overmolding & 2k Molding

Overmolding& 2k Molding

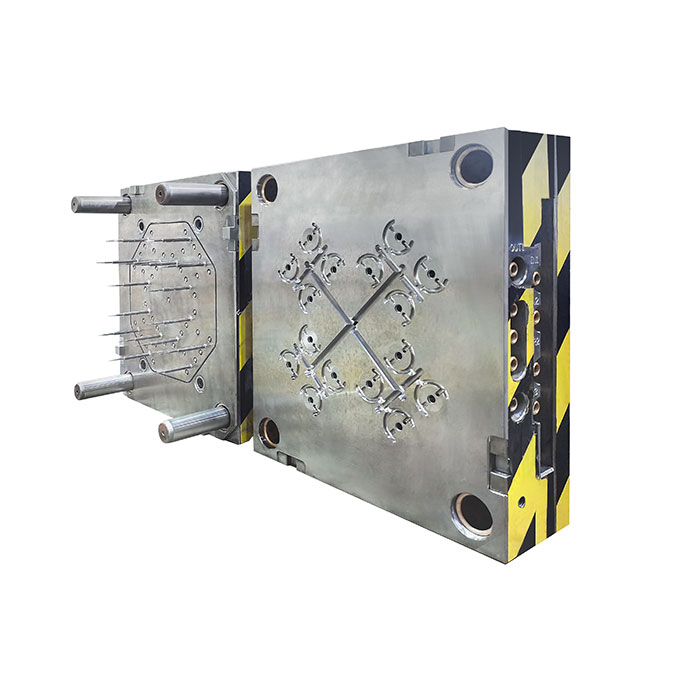

The same type of material of different colors is usually used for two-color injection molding(or 2k injection molding)so that the bonding strength of the first color and the second color plastic is the best, but due to the functional requirements of the product, the performance difference of the two materials actually used may be very big, if the elastomer is injected into the surface of a rigid material, the most difficult thing to solve during 2k molding over moldingprocess is the delamination and shedding of the bonding surface of the two materials.

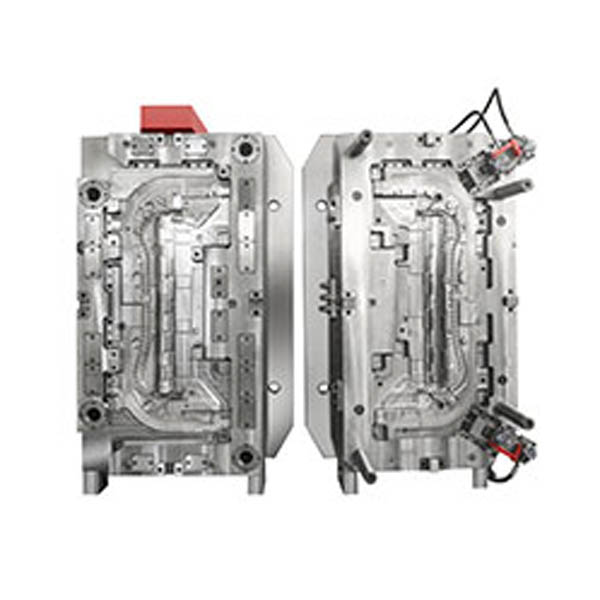

OVER-MOULDED 2K MOLDSFOR SALE

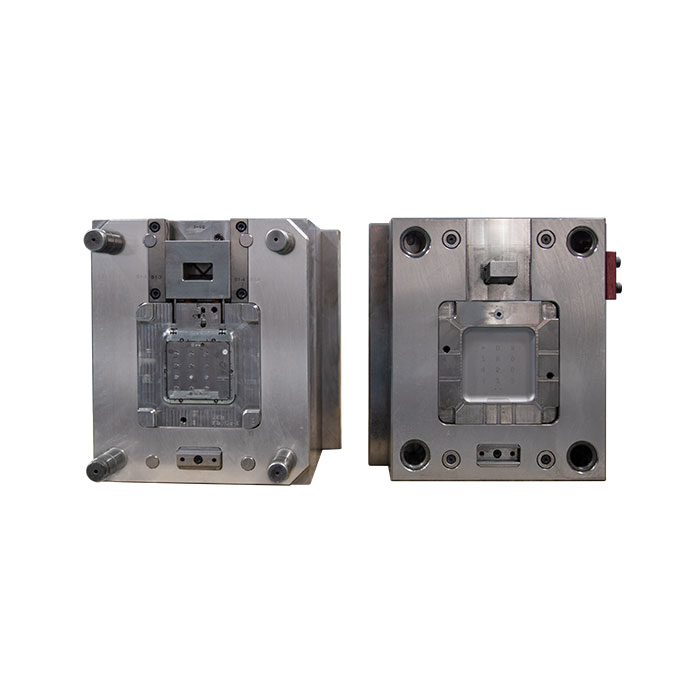

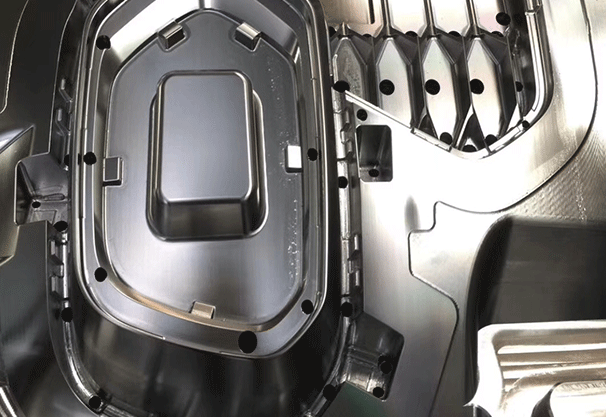

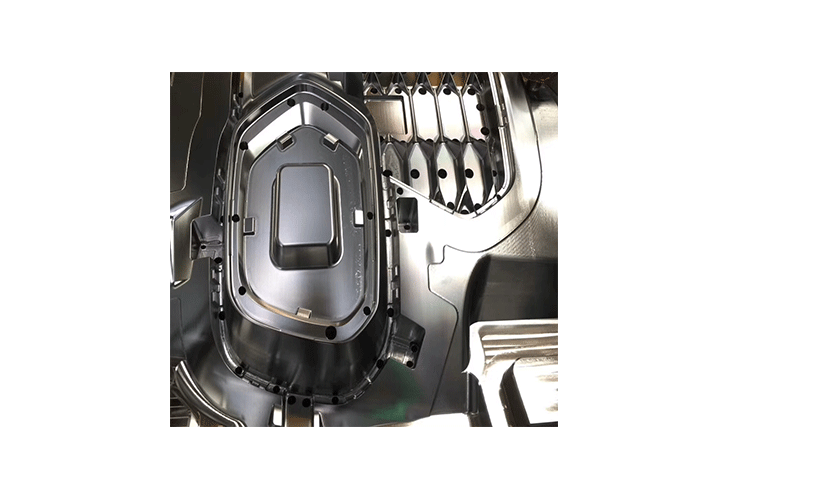

Water Proof Plastic Enclosure Mold

The product will be made by two times, which will inject the second piece after finishing the first piece in the other mold and different injection machine, normally will be no specific request for 2 different pieces injection time, injection machine.

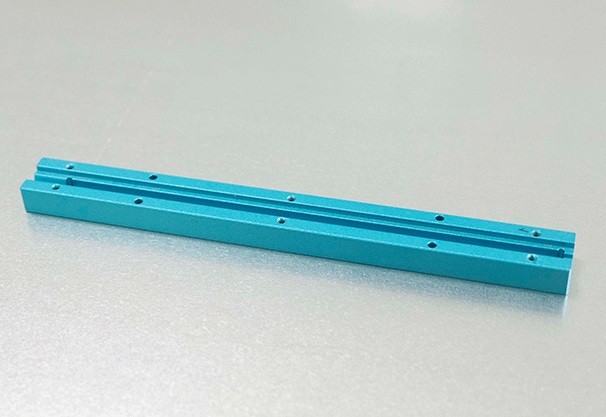

Drip Tip Mold

The two-color molding will be made in one same injection machine at the same time by 2 times injection, with 2 injection barrels and 2 different injection gates by 2 different molds, but the product will be picked up one time, it will request 2 molds in one specific 2k injection machine to finish final injection.

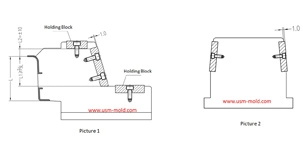

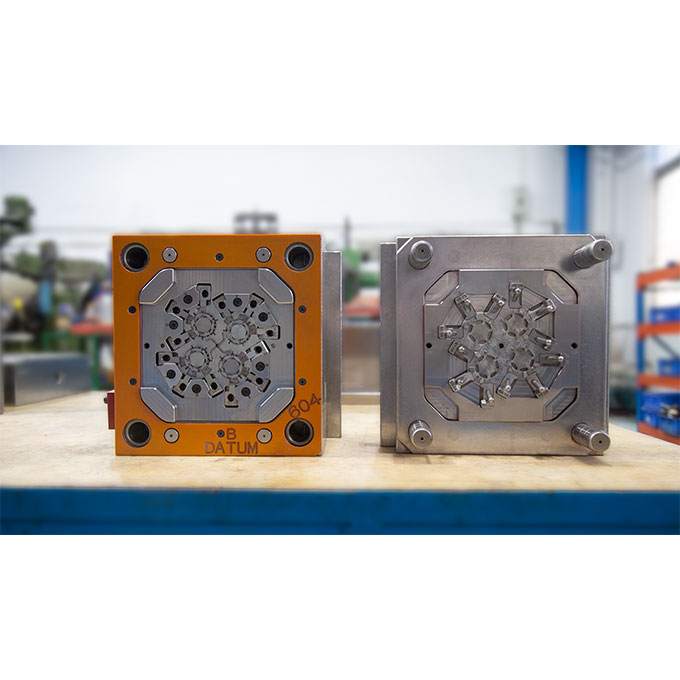

2K Mold

This mold will be put with a movable core on gate position of the core side, the movable core is pushed to the rising position when injecting the first-color material, and the first color part is solidified, After that, the movable core return back through the action of the hydraulic device, at this time, another barrel injects the second color material into the space left by the retreat of the core, the mold is opened and the part is taken out after finishing one injection after it's solid.

Material Selection For 2K Plastic Injection Moulding

In addition to meeting the requirements of product function and appearance in the material selection of two-color products, whether the adhesion between raw materials can be solved well will be related to the success of two-color products in 2k moulding process is also the difficulty of 2k moulding technology.

The following four points should also be considered in the selection of materials for two-color injection molded products:

2K Molding Design Guide

Structural design is the most important part of 2k molding product design, the structure design of the product should not only consider the function of the product but also consider whether it meets the processing conditions and the complexity of the processing mold, in the design of two-color injection products, in addition to the issues to be considered for ordinary injection products, the following aspects should also be considered:

As a 2k molding manufacturer, we will do our best to meet all the needs of customers.

There are many injection moulding manufacturersin China, but we are one of the best choices for you.

Send product request

Other supplier products

| Pre-Deformation Mold | Pre Deformation Mold When the plastic material rushes into the mold cavity, it loses heat due to heat conduction, and the melted plastic will free... | |

| 2K Mold | 2KMolds The rotary mold is composed of two-cavity and core sides, the two core sides are the same, only the cavity sides is different which the ... | |

| Plastic Household Mould | Plastic Household Mould The smart switches and smart sockets of the smart home systems have the same specifications as normal power switches and s... | |

| Medical Pipette Tip Mold | Medical Pipette Tips USM as a medical plastic mouldingsupplier provides products including medical device plastic parts, suction tips, blood colle... | |

| Insert Mold Parts | Insert Moulding Products The combination of easy plasticity and elasticity of plastic and rigidity, strength and heat resistance of metal can be... |

Same products

| Mold Components | Seller: Packson Mold Co.,Ltd | We provide custom made plastic parts-Sliders, inserts, lifters, blocks, ejector pins, and other m... | |

| Custom Metal Machining Parts | Seller: Packson Mold Co.,Ltd | Packson provides our customers a various CNC machining services to our customers, including milli... | |

| Clean Room Injection | Seller: Packson Mold Co.,Ltd | Packson - Medial Injection Moulding Cleanroom Expert Packson specializes in delivering top-notch ... | |

| Medical Plastic Injection Molding | Seller: Packson Mold Co.,Ltd | Packson - Medical Plastic Injection Molding Expert Packson sets itself apart from other medical i... | |

| CNC Metal Machining Parts | Seller: Packson Mold Co.,Ltd | Packson is a contract manufacturer specializing in CNC Milling, CNC Turning, CNC Drilling service... |