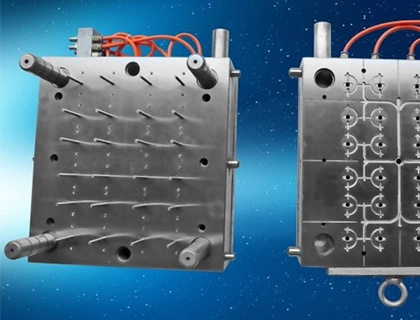

SYRINGE MOLD/MOULD

LINKPLUS provide precision molds used in manufacturing of each components of the various syringes such as disposable syringe, Insullin syringe, safety syringe, AD syringe. Including barrel, plunger, gasket. It's customizable according to customer production need. Our syringe molddesign is reasonable, with a sturdy structure and stable performance, which can greatly improve production efficiency and mold service life.

WHAT IS SYRINGE MOLD USED FOR?

Syringe moldingis a specialized tool used in the manufacturing of syringes. It is designed to produce precise and consistent shapes of plastic or glass components that make up the syringe, including the barrel, plunger, needle cap, needle hub and so on.

HOW DO YOU USE SYRINGE MOULD?

Steps for mold installation.

1

Confirm that the injection molding machine power is turned on.

2

Click the manual button of the injection molding machine to put it in manual mode.

3

Click the oil pump button of the injection molding machine to start the oil pressure system of the injection molding machine.

4

Transport the molds in place and confirm that they match the production accessories.

5

Use a sling to slowly lift the mold slightly above the injection molding machine, and move the sling bracket so that the mold is above the installation position. Be careful not to cause the mold to collide with the surveillance camera and robotic arm.

6

Slide the protective sleeve of the injection molding machine guide pillar to the appropriate position and slowly lower the mold. The operator should support the top of the mold to avoid it Intense shaking. The operator must control the mold and prohibit it from hitting the guide pillar. When the guide pillar is hit, it will cause concave and convex deformation, Damaging the sealing of the oil pressure system.

7

Lower the mold to the appropriate position, install the positioning flange and protective ring, adjust the mold and sling bracket to make the mold flange and protective ring fit with the injection hole of the injection molding machine.

8

Close the sliding doors on both sides of the injection molding machine, click the mold adjustment button of the injection molding machine, and enter the mold adjustment state.

If you are looking for a reliable medical molding manufacturer, don't hesitate to contact us!

Send product request

Other supplier products

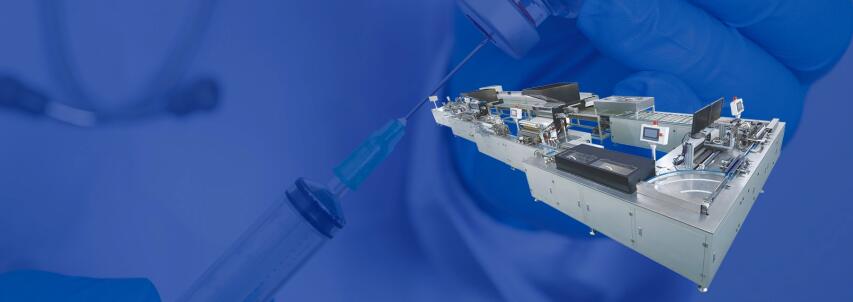

| NEEDLE MACHINE | The LINKPLUS syringe and needle making machineis a specialized piece of equipment that creates needles of the highest quality for use in IVs, injec... | |

| NEEDLE ASSEMBLY MACHINE | LINKPLUS's Needle Assemble Machineis an integral part of the process for manufacturing hypodermic needles used in medical instruments. During assem... | |

| SYRINGE BARREL PRINTING MACHINE | A syringe barrel printing machine is a specialized printing machine used to print on syringe barrels. Syringe barrels are the cylindrical plastic t... | |

| MEDICAL TUBING EXTRUSION MACHINE | LINKPLUS manufactures Medical Tubing Extrusion Machines that utilize a plastic extruder, die, and cooling system to shape thermoplastic material in... | |

| DRIP CHAMBER ASSEMBLY MACHINE | The Welinktech Drip Chamber Assemble Machine is a state-of-the-art piece of equipment used for precisely assembling IV drip chambers. These machine... |

Same products

| Durable and Reusable YCS Welding Oil Booster for Professional Repairs | Seller: Shenzhen Wikshu Technology Co. | Description YCS Z04 Solder Flux Booster 5ml Welding Oil Syringe Push Rod for pushing sol... | |

| YCS-Z04 Booster Welding Oil Solder Flux Syringe | Seller: ShenZhen VIP FIXPHONE Technology Co., Ltd, | Description YCS Z04 Solder Flux Booster 5ml Welding Oil Syringe Push Rod for pushing sol... | |

| RFID microchip implant | Seller: XIUCHENG RFID | Dimension:1.25 X 7mm / 1.4 X 8mm / 2.12 X 8mm /2.12 X 12mm / 3 X 15mm / 4 X 32mm RF Interface:IS... | |

| RFID microchip implant | Seller: XIUCHENG RFID | Dimension:1.25 X 7mm / 1.4 X 8mm / 2.12 X 8mm /2.12 X 12mm / 3 X 15mm / 4 X 32mm RF Interface:IS... | |

| Multi Channel Syringe Pump | Seller: Nanjing Runze Fluid Control Equipment Co.,Ltd | Multi Syringe Pump is a precision syringe pump specially designed for high precision liquid handl... |