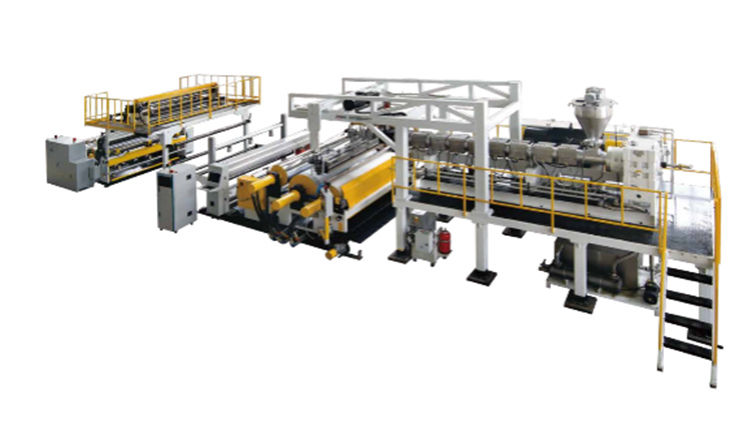

EVA/POE Film Extrusion Line

JWELL POE/EVA film production line features:

The salivating extruder adopts multi-machine co-extrusion single screw extruder, which can be extruded by EVA and POE layers, ensuring performance and saving cost to a great extent.

Roller body part adopts double-sided embossing.

The cooling part of EVA/POE Film Extrusion adopts cooling unit and stress-relieving cold bed to make the film run smoothly and fully finalize the design to ensure shrinkage rate less than 3%.

The whole EVA/POE Film Extrusion Line adopts PLC automatic control to realize man-machine interface operation. The production line is equipped with online quality monitoring and control system to ensure the qualified rate of products.

The coiling machine is produced by Jwell machine company, the configuration requirements can be adjusted flexibly, which can realize automatic production and save labor cost.

EVA Extrusion Line Performance and Advantages

Performance characteristics of EVA and Poe film production line of Jwell company:

(1) The casting extruder adopts EVA / POE special single screw extrusion, and the screw barrel constant temperature circulating water cooling system solves the technical difficulties of EVA plasticization and non-crosslinking. And it can realize multi machine coextrusion, and the two materials can be used together to ensure the performance and save the cost at the same time.

(2) The roll body adopts double-sided embossing and solves the technical difficulties of adhesive film sticking to the roll.

(3) The cooling part of EVA and Poe film extrusion line adopts cooling roller and stress relief cooling bed to make the rubber film run smoothly and fully set, so as to ensure that the shrinkage rate is less than 3%.

(4) The whole EVA and Poe film extrusion line adopts PLC automatic control to realize the operation of man-machine interface.

(5) The EVA and Poe film production line is equipped with online quality inspection and control system to ensure the product qualification rate.

(6) The patented full-automatic winder can realize the full-automatic production of the whole machine and save labor cost.

JWELL Extrusion Machinery Co. Ltd is a high-tech manufacturer specializing in the research and development of yarn spinning machine, pvc sheet extrusion line.

Other supplier products

|

|

POY Spinning Machine |

POY spinning machine adopted Newly designed Spin-Beam with less energy consumption by 30% compared with conventional ones. Adopted Bottom mounted ... |

|

|

Plate Extrusion |

Plate extrusionis one of the screw pla extruder. The working mechanism of screw plastic extruder is to rely on the pressure and shear force generat... |

|

|

Plastic Profile Extrusion Line |

This plastic profile extrusion lineconsists of Single Screw Extruder, Vacuum Calibration Table, Haul-off Unit, Cutter and Stacker, the producing li... |

|

|

EVA/POE Film Extrusion Line |

JWELL POE/EVA film production line features:

The salivating extruder adopts multi-machine co-extrusion single screw jwell extruder china, which ... |

|

|

ASA Film Extrusion Line |

Because of its outstanding anti-aging properties, ASA films are widely used in the field of roofing tiles. JWELL ASA thin film production line can ... |

All supplier products

Same products