Single Side Hydraulic Decoiler

SINGLE SIDE HYDRAULIC DECOILER

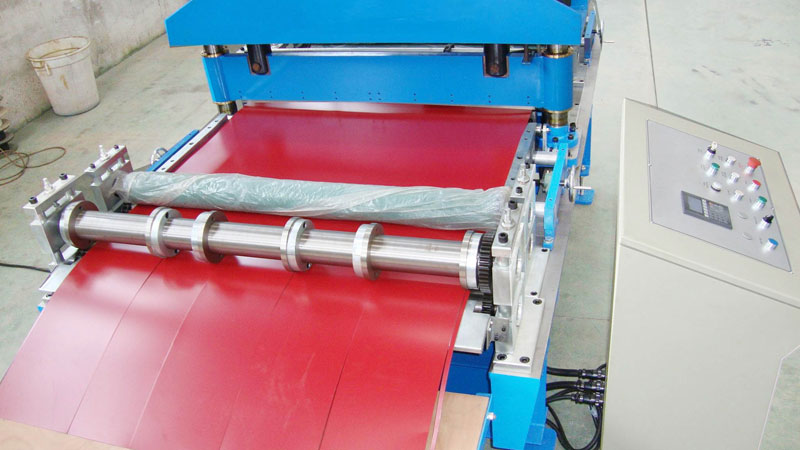

The regular hydraulic decoilermachine adopts a cantilever-type structure. It Includes a machine frame, cantilever type extension, decoiler driving system (by motor), Hydraulic system, and electric control system, Etc., with the function of installing and unwinding the coil.

As for the with arm-type cable decoiler, the machine is composed of mainframe, arm-type hydraulic expanding axis, motor releasing of the transmission system, coil car, hydraulic system, PLC control system, which are used to realize the function of coil loading and unloading. The decoiler is feeding work in the production line for the roll forming machine.

Characteristic of Structure of the Machine

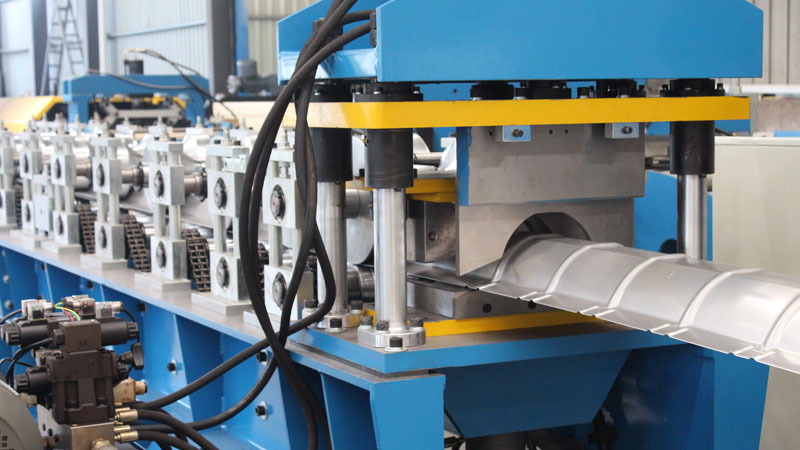

The frame using beam steel and shot blasted process after welding.

The shaft of the cantilever type extension cope: Φ465-Φ515,controlled by the valve hydraulic system, and the mechanical parts.

Separately working, through reducer by Chain driving the shaft to decoiling or recoiling the coil material. When working assort with the forming machine, the hydraulic uncoilermachine uncoils the coil actively and controls the uncoiling speed by ultrasonic sensor.

Using separate hydraulic systems to support the working of the decoiler.

Set electric control system separately, realized the extension of the center shaft of uncoiler machine, and driving the shaft forward, backward, and step motion forward and backward. The ancillary shoring is for supporting the main uncoiling machine so as to make the hydraulic decoiler with carbearing capacity become larger.

Series Product Differences of Single Side Hydraulic Decoiler

|

Item |

RFT-5TCP |

RFT-8TCP |

RFT-10TCP |

RFT-15TCP |

remark |

|

Capacity |

5000Kgs |

8000Kgs |

10000Kgs |

15000Kgs |

|

|

ID of the coil |

φ508mm |

φ508mm |

φ508mm |

φ508mm |

extension cope: Φ465-Φ515 |

|

Width of the coil |

1000-1550 |

1000-1550 |

1000-1550 |

1000-1550 |

|

|

φ1350mm |

φ1350mm |

φ1350mm |

φ1350mm |

||

|

orφ1750mm |

orφ1750mm |

orφ1750mm |

orφ1750mm |

||

|

Speed of decoiling |

≤45m/min |

≤45m/min |

≤45m/min |

≤45m/min |

mandrel running speed: 23r/min |

|

Power of the motor |

|||||

|

Hydraulic power |

3KW |

3KW |

3KW |

3KW |

|

|

The hydraulic Pressure |

Max20Mpa |

Max20Mpa |

Max20Mpa |

Max20Mpa |

|

|

Power Source requirement |

3 phase AC400V/50Hz |

3 phase AC400V/50Hz |

3 phase AC400V/50Hz |

3 phase AC400V/50Hz |

380V to 460V 50Hz/60Hz can be customized |

|

Maximum working current |

22A |

22A |

27A |

27A |

|

|

Short-circuit current |

6KA |

6KA |

6KA |

6KA |

|

|

Pressing arm |

Optional/Pneumatic/Hydraulic |

Optional/Pneumatic/Hydraulic |

Optional/Pneumatic/Hydraulic |

Optional/Pneumatic/Hydraulic |

|

|

Manual supporting |

Without this configuration |

Without this configuration |

Standard configuration |

Standard configuration |

|

|

Overall dimensions |

4100*1100*2150mm |

4100*1150*2150mm |

4200*1800*2000mm |

4200*2100*2100mm |

|

|

Weight |

4050Kgs |

4100Kgs |

5300Kgs |

5600Kgs |

|

|

Working direction |

Optional |

Optional |

Optional |

Optional |

Right to Left/Left to Right |

|

Hydraulic coil cart |

Optional |

Optional |

Optional |

||

If you need any kinds of cold roll forming machine, please contact us, as a professional roll forming machine supplier, RF is willing to offer you high quality products.

Send product request

Other supplier products

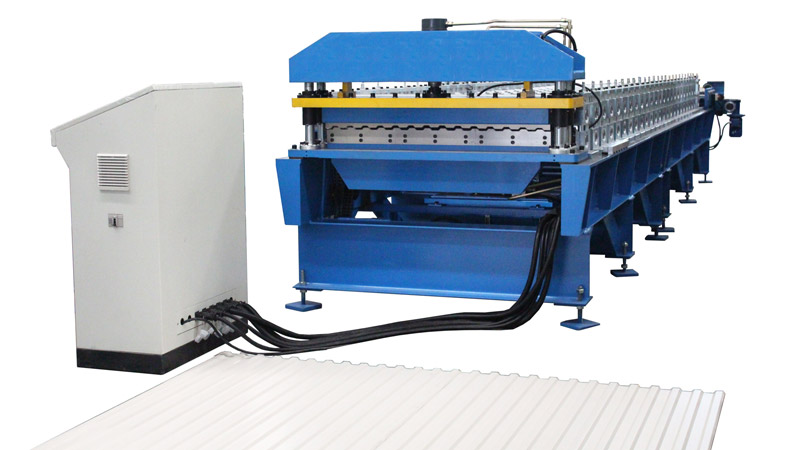

| Roof And Wall Panel Roll Forming Machine | The cold roll forming machine is the equipment for continuously processing metal sheets of a coil, a strip, by a multi-pass forming roller which is... | |

| Roof Panel Roll Forming Machine | This metal cladding roll forming machineis used to roll-form metal roof panels and metal wall panels. The roll forming lineusually includes metal d... | |

| Guardrail roll forming machine | Hangzhou Roll Forming Technology Co., Ltd is a professional manufacturer and exporter of all kinds of standard and non-standard cold roll forming l... | |

| Roofing Tile/Glazed Tile Making Machine | Roofing Tile & Glazed Tile Making Machine is for continuously roll forming and pressing step tiles sheets. The step length of this glazed roof ... | |

| Ridge Cap Roll Forming Machine | ridge cap machineIntroduction This machine is used to make ridge capping. Ridge capping is a critical part of the structure of a roof. Ridge cappi... |

Same products

| 9606 Angle Grinder Chamfering Stand | Seller: Zhejiang Shijing Tools Co., Ltd. All Rights Reserved. | 1. High compatibility; fits over 90% of models on the market. 2. Constructed primarily from alum... | |

| 3025 Manual Ceramic Cutting Machine | Seller: Zhejiang Shijing Tools Co., Ltd. All Rights Reserved. | The 3025 Manual Ceramic Cutting Machine is a versatile and reliable tool designed for precision c... | |

| China factory Open module ADAM-5056S for power station Sold by YOYIK | Seller: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | China factory Open module ADAM-5056S for power station Sold by YOYIK. Deyang YOYIK is a professio... | |

| Manual Tile Cutting | Seller: Zhejiang Shijing Tools Co., Ltd. All Rights Reserved. | Manual tile cuttingis a skill that has been honed over centuries, a craft that requires patience,... | |

| Downspout Roll Forming Machine | Seller: Zhejiang Jinggong Science & Technology Co., Ltd. | This downspout pipe roll forming machinecan produce the sealed color water pipes by forming the c... |