Battery Tray Holder

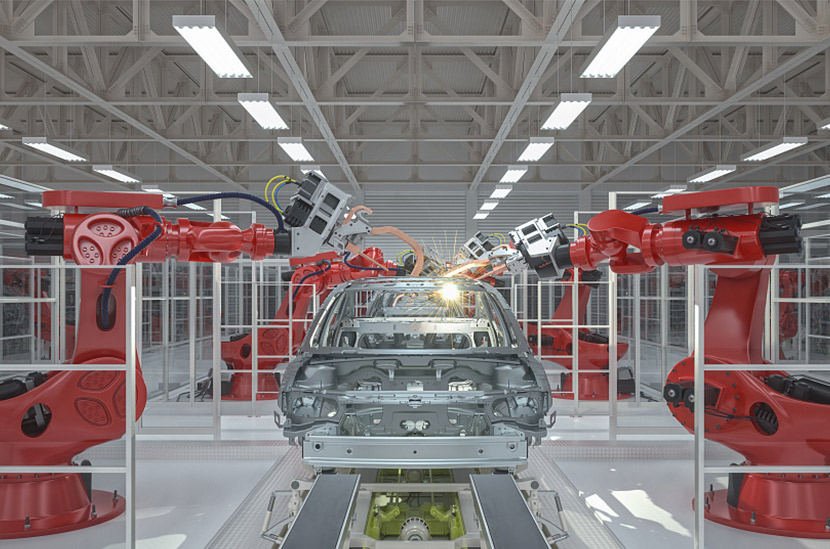

Aluminium alloy battery tray/ lower box of battery pack is mainly made of steel and aluminium alloy. Aluminium alloy is favored by more and more automobile OEMs and battery tray manufacturersaround the world because of low destiny of battery traybracket and various forming processes, which can meet the requirements of electric vehicle lightweight. At present, the aluminium alloy extra large battery tray has two process schemes: integral casting and aluminium profile welding. Friction stir welding has been widely used in universal battery tray manufacturing because of its non-melting, automation, intelligence, environment-friendly and integrated characteristics.

As one of the friction stir welding companies, Cheeven provides quality custom battery trays and battery tray kit wholesale at great market prices!

For more informationabout battery tray price, please feel free to contact us!

Send product request

Other supplier products

| Die Casting Injected Metal Assembly | As for the injected metal assembly, it has a stronger frame, higher strength, and is impact resistant. Press the molten alloy into the precision di... | |

| Die Casting Lighting | Ningbo Cheeven New Materials is one of the China Led FSW Manufacturers and die casting lightingfactory.We have a team of die casting lighting to de... | |

| FRICTION STIR WELDING IN AUTOMOTIVE INDUSTRY | FRICTION STIR WELDING IN AUTOMOTIVE INDUSTRY The development of new energy vehicles in the world started with hybrid power, and then gradually e... | |

| Carbon Nanotube Clothing | Due to the structural characteristics of carbon nanotube fabric, 95% of the thermal radiation is far-infrared rays that match the wavelength of hum... | |

| Copper Nickel Indium Powder | Copper nickel indium coatingis a superalloy powder for aerospace parts coating and 3D printing. Copper-nickel indium coating has excellent powder p... |

Same products

| Electric water tank | Seller: INLIGHT NEW ENERGY | Electric Water Heater Tanks are reliable, efficient storage solutions designed to provide a const... | |

| Top Heat Recovery Gas Heating Unit | Seller: Fujian Air Technology Systems Co., Ltd | Applications: solving the heating needs for high and large space(H:4-30m). Adopting direct combus... | |

| AIFEN F5 Pro 1000W Hot Air Gun for Electronics Maintenance | Seller: Phonefix | AIFEN F5 PRO High Power Hot Air Rework Station delivers 1000W performance for mobile phone repair... | |

| YCS R1 Ultra Hot Air Rework Station for BGA and CPU Repair | Seller: Phonefix | The YCS R1 Ultra and YCS R1 Ultra Limited Edition 1450W High Power Hot Air Gun Rework Station exc... | |

| MECHANIC 958HT Small Digital Hot Air Gun For IC Disassembly | Seller: ShenZhen VIP FIXPHONE Technology Co., Ltd, | Description Mechanic 958HT 600W Portable Handheld Hot Air Gun with HD Digital Display and Button ... |