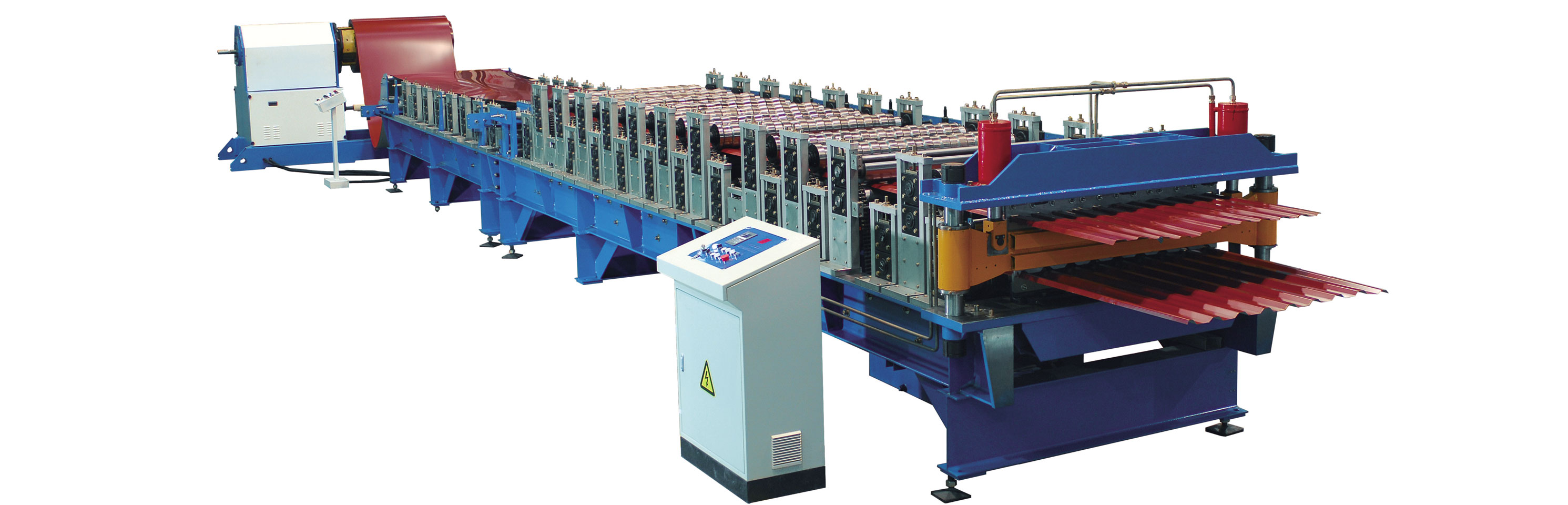

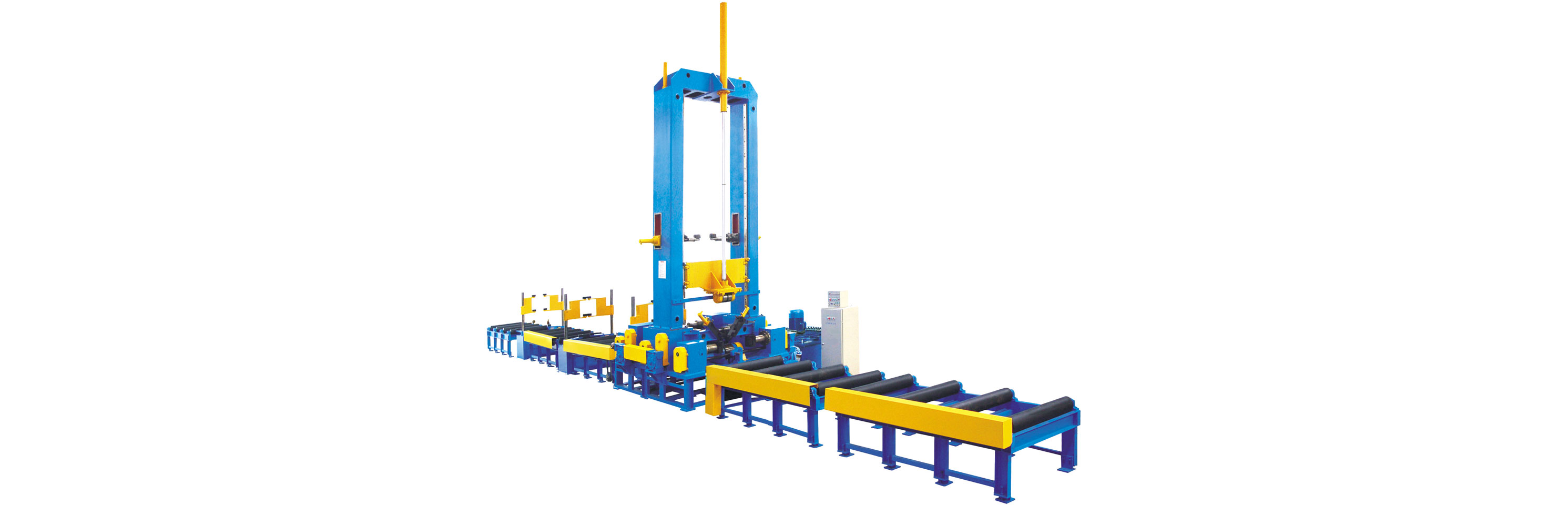

EPS Sandwich Panel Production Line

Main structure features ofEPS Sandwich PanelMachine

1) This EPS sandwich panel making machinehas the specification: nice appearance, low noise and high efficiency.

2) The EPS sandwich panel production lineis welded by H-beam with shot blasting treatment on the surface, so the whole structure is simple and stable.

3) Consecutive laminating body transmission of the EPSsandwich panel making machine adopts worm and worm gear in order to control the producing speed steadily. The consecutive laminating body can cut to length with the advanced frequency control.

4) The EPSsandwich panel machineis equipped with three groups heating system to adapt the environmental temperature in different places.

5) Glue Providing system of our EPSpanel machineis driven individually. The horizontal compound, glue evenly, without any pollution.

6) Consecutive laminating body is long to guarantee the flatness of the sandwich panel.

7) The moving stroke of the cutting system is long to extend the life of the cutting tool.

Contact us forEPS sandwich panel machineryprice! Or contact us for more information about othersandwich panel production machinery/line.

Main Technical Parameter of EPS Panel Production Line

Specification ofSandwich panel produced by Jinggongsandwich panel making machine:

Length: Min cutting length is 2 m

Max cutting length is 15m

Width: (see profile drawing)

Thickness: (see profile drawing)

Raw material specification:

coil thickness: 0.4~0.6 mm (steel be flat without ups and downs, deformation and bending)

sheet yield stress: ≤235MPa

coil max width: 1200 mm (tolerance±2mm)

coil max weight: 4T

coil ID: Φ500 and Φ600 mm

coil OD: Φ1000 mm

EPS material: density is≥18㎏/m3, unstraight of each side ≤1㎜/m, curve ≤3㎜/m, surface be even, unevenness smaller than 1.5mm/m, EPS material single piece length more than 3m.

Material suitable shape: see profile drawing

Material suitable width: minimum shall be 1/2mm of the finished panel width.

EPS panel production line specification:

Work line speed: 1000-3000mm/min (frequency speed adjustment).Attention: depending on glue brand, temperature and proficiency of operators.

Machine length: about 40 m

Working height: 1050 mm(panel output height)

Laminating effective length: 7.5m

Control way: adopt industrial computer PLC

Total power: about 35 kw

Power: 380V/3phase/50 Hz

control voltage: 24 V/110 V/220 V

pneumatic: 0.7 Mpa (self-prepared by the factory)

best working temperature: around 25℃

As a sandwich manufacturing company, we will do our best to meet all the needs of customers.

Send product request

Other supplier products

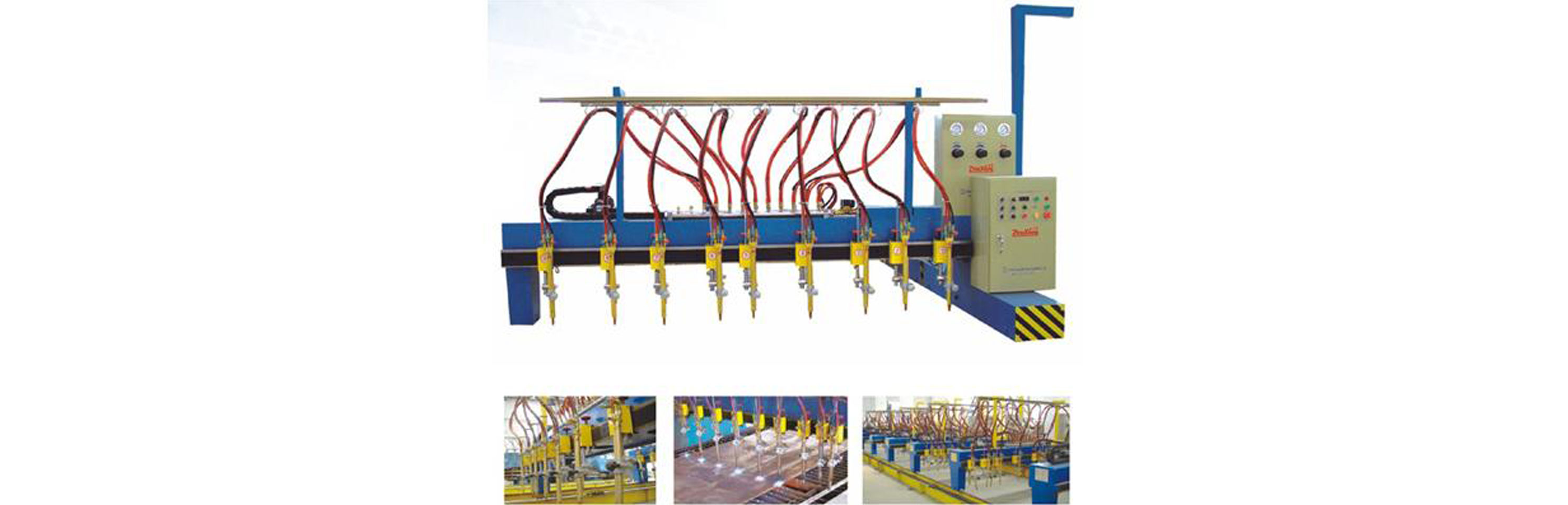

| CNC Flame Cutting Machine | The cnc flame cutting machineis a multifunctional thermal auto-cutting device combined microcomputer controlling, precise machinery and oxygen-acet... | |

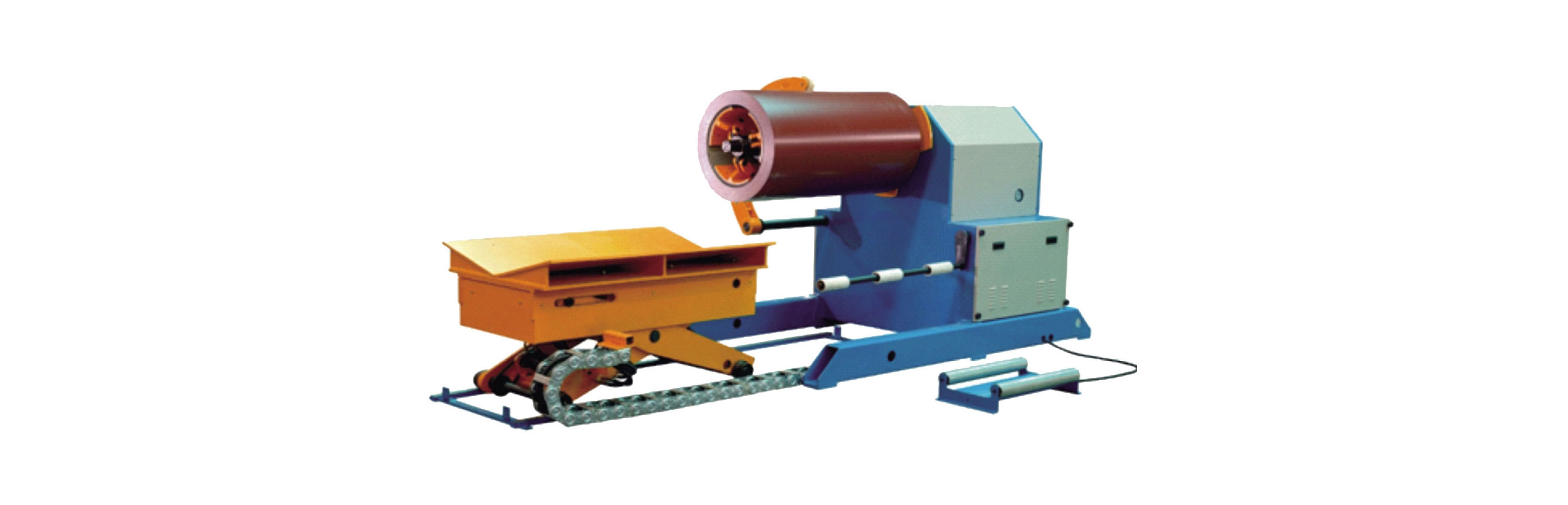

| Introduction of Uncoiler and Its Functions and Features | Uncoileris special equipment for sheet metal leveling. It is applied to the leveling line of steel plates and uneven plates, which can form uncoili... | |

| C/Z Purlin Roll Forming Machine | Thec purlin roll formercan form hot/cold rolled metal strip through leveling, cold roll forming, punching and cutting off to produce C type or Z ty... | |

| Downspout Roll Forming Machine | This downspout pipe roll forming machinecan produce the sealed color water pipes by forming the colored steel sheet and whipstitch it. The downspou... | |

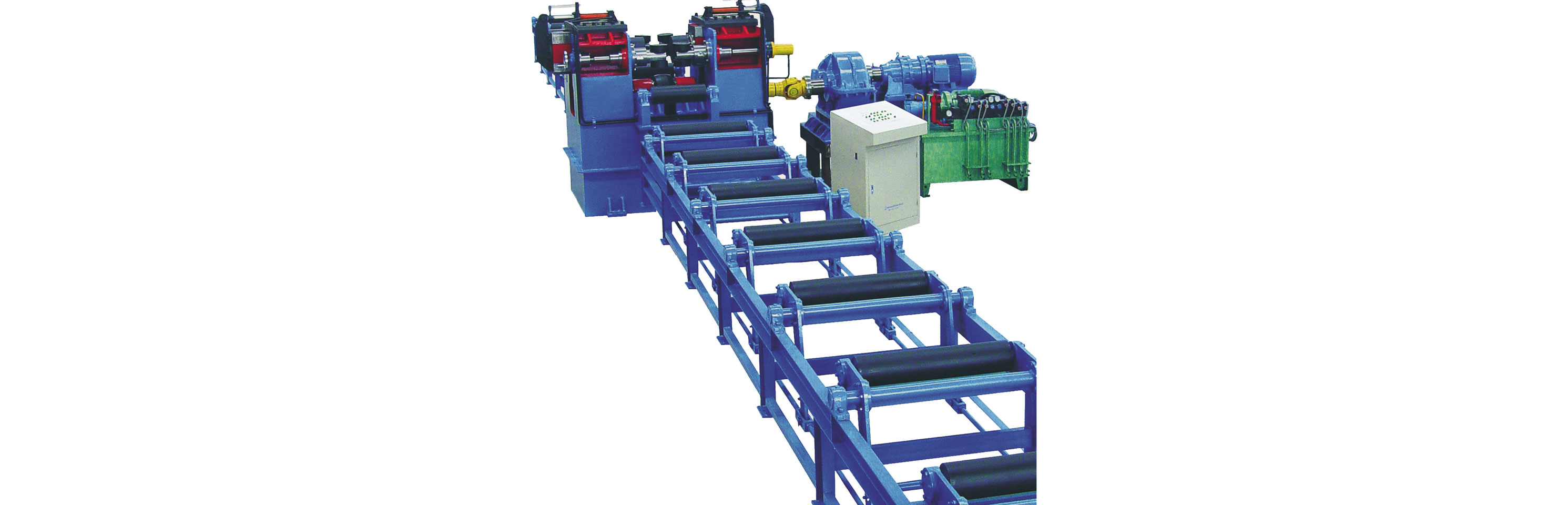

| Roller Design and Operating Rules of Cold Roll Forming Machine | The cold roll forming machine saves us a lot of time in the production process and also makes our products more perfect and competitive. Now, le... |

Same products

| High Speed Roll Forming Machine | Seller: Zhejiang Jinggong Science & Technology Co., Ltd. | The high speed formingmachine is the new type line which is produced both by our company and Form... | |

| H-Beam Welding Line | Seller: Zhejiang Jinggong Science & Technology Co., Ltd. | Hbeam welding machineconsists of an assembling machine, front welding machine, turn-over device, ... | |

| H-Beam Straightening Machine | Seller: Zhejiang Jinggong Science & Technology Co., Ltd. | HBeam StraighteningMachine is mainly used for the angle distortion straightening of heavy H-beam,... | |

| H Beam Shot Blasting Machine | Seller: Zhejiang Jinggong Science & Technology Co., Ltd. | Hbeam shot blasting machineis designed and manufactured to clean the surface of the section steel... | |

| H-Beam Assembling Machine | Seller: Zhejiang Jinggong Science & Technology Co., Ltd. | The clamping and alignment of the web plate and flange plate will be done in h beam assembly mach... |