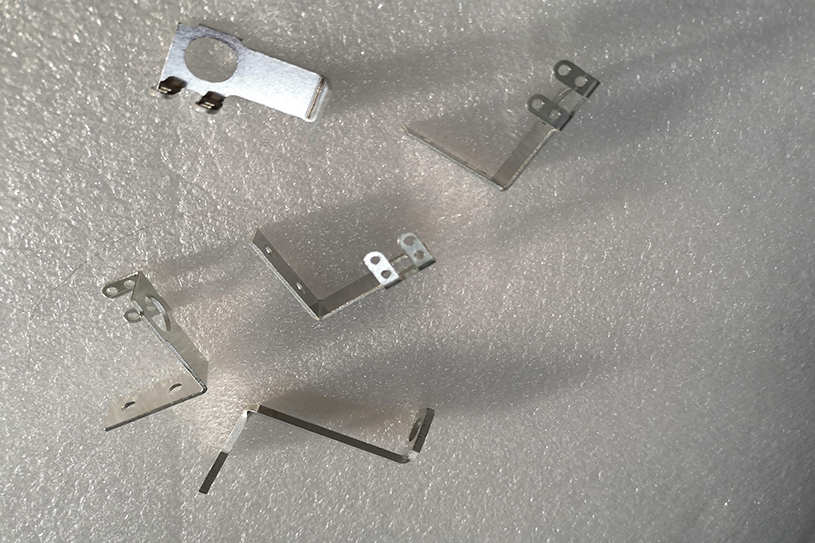

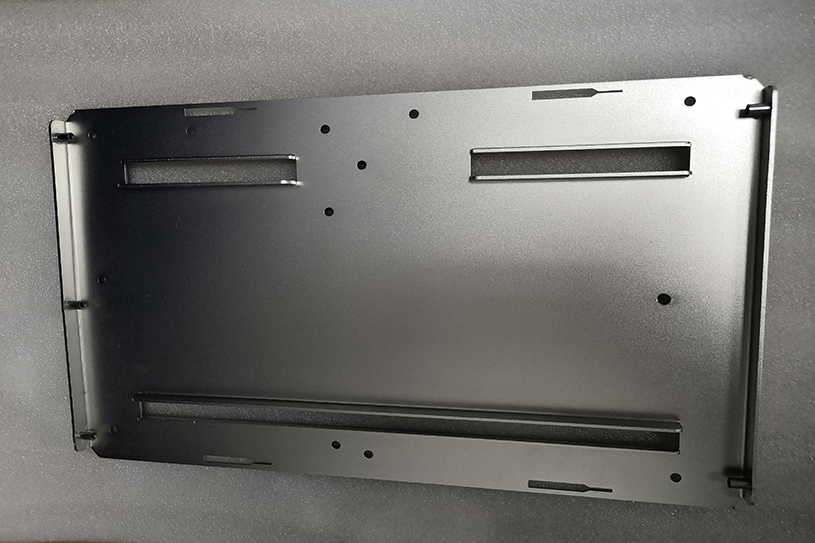

Bending Fabrication Customized Parts-2020

Tin and its alloy is a kind of coating with good weldability and corrosion resistance. It is widely used in electronic components and printed circuit boards. In addition to the physical methods such as hot dipping and spraying, the methods such as electroplating, dip plating and chemical plating have been widely used in industry due to their simplicity.

Immersion tin plating

Dip plating is to dip the workpiece into the solution containing the metal salt to be plated, and deposit the metal coating on the surface of the workpiece according to the principle of chemical replacement. This is different from the general principle of electroless plating, because the solution does not contain reducing agent. It is also different from contact plating, which means that when the workpiece is immersed in the salt solution of the metal to be plated, it must be closely connected with a reactive metal, which is an anode entering the solution and releasing electrons. The metal ions with higher potential in the solution get electrons and deposit them on the surface of the workpiece. Dip tin is applied only to iron, copper, aluminum and their respective alloys.We use this method for coating the bending fabrication customized parts.

Electroless tin

No reducing agent used for copper or nickel autocatalytic deposition can be used to reduce tin. The simplest explanation is that the hydrogen evolution overpotential on the surface of tin is high, and the above reducing agent is hydrogen evolution reaction, so it is impossible to reduce tin ions to tin. In order to electroless tin plating, it is necessary to choose another kind of hydrogen-independent strong reductants, such as Ti3+, V2+, Cr2+, etc., only T3+/Ti4+ system has been reported.

Advantages:

Surface treatment: tinplating

Raw material: copper parts

Packaging Details: Cartons and bags(we offer customized package and custom sheet metal bending.)

As one of the most professional sheet metal components manufacturersin China, Shenzhen HSJMetal Fabrication Co., Ltd. provides research and development, production of metal fabrication and different kinds of stamping parts,metal bending parts,precision machining parts,CNC machine lathe car spare parts, and other industrial parts. RFQ today!

Send product request

Other supplier products

| Products | Aircraft sheet metal fabricationis the method of building machines and structures from raw metal materials like plate metals. aluminium sheet fabri... | |

| Custom Laser Welded Parts | Custom Laser Welded Parts Material: Stainless Steel/Aluminum/Iron/SECC Thickness: Surface treatment: Spray and powder coating Process: ... | |

| SUS Parts Laser Cutting | Detail The alloy of copper and zinc is called brass! The content of brass elements affects its processing properties. Our brass has strong wear res... | |

| CNC Metal Parts | CNC metal parts are about to turn the manual work into computer programming. Of course, you need to have experience in manual processing. General C... | |

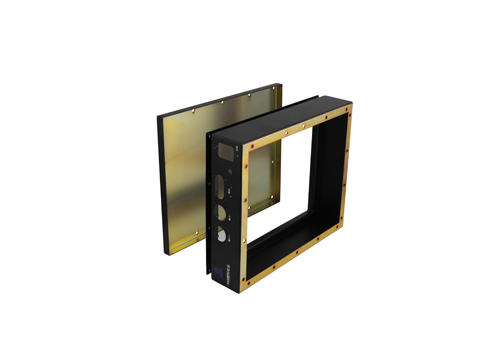

| SHEET METAL CABINETS | Sheet metal has the characteristics of lightweight, high strength, electrical conductivity (can be used for electromagnetic shielding), low cost, a... |

Same products

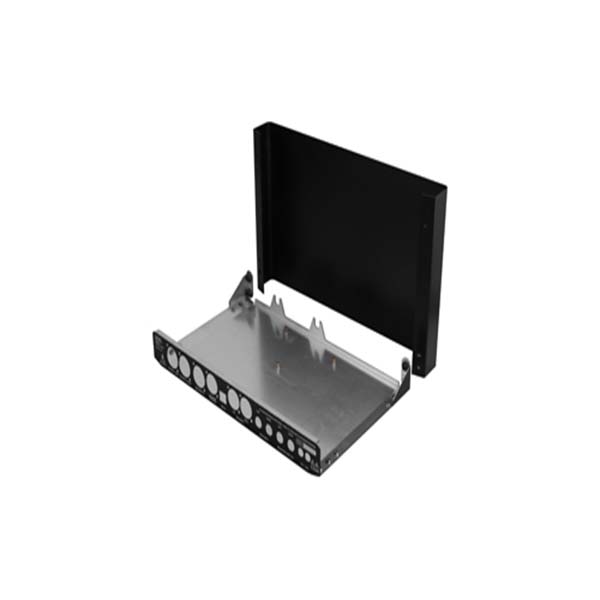

| Combined Electronic Enclosures-2020 | Seller: Shenzhen HSJ Metal Fabrication Co.,Ltd. | Our box for circuit boardis made of galvanized sheet and the surface is not treated. the producti... | |

| CNC Stainless Steel Parts-2020 | Seller: Shenzhen HSJ Metal Fabrication Co.,Ltd. | M aterial : their Tolerance:Machining standards: limited linear dimension tolerance ±0.1m... | |

| CNC Custom Aluminum Parts-2020 | Seller: Shenzhen HSJ Metal Fabrication Co.,Ltd. | Material: aluminum Process: Cnc machine-wire drawing-reveting-anodizing-silk printing Color: st... | |

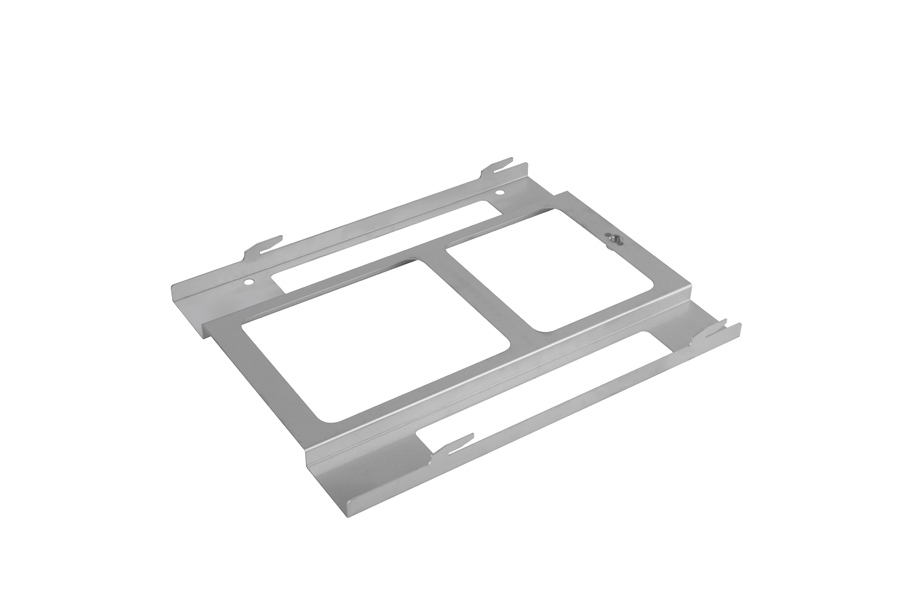

| Bending Perforated Aluminium Sheet-2020 | Seller: Shenzhen HSJ Metal Fabrication Co.,Ltd. | Are you looking for reliable sheet metal manufacturing companies? Details of aluminum perforated... | |

| Bending Metal Plate-2020 | Seller: Shenzhen HSJ Metal Fabrication Co.,Ltd. | Process: Blanking bend anodized sandblasted rivet. Material: aluminum plate. Power box accessor... |