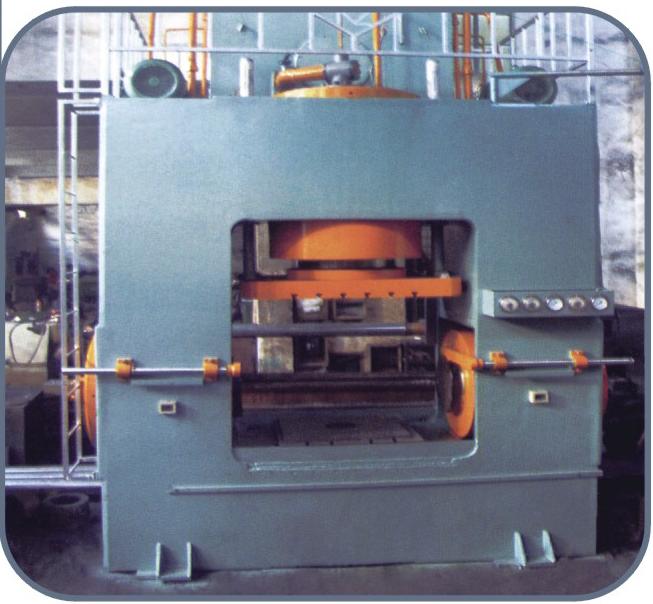

Four cylinder elbow making machine

Four cylinder elbow push system machine operation method

This push the machine is equipped with 6 sets of hydraulic pump, main pump 2 sets, backward pump 2 sets, feeding system with pump 1, core rod to adjust and gate pump 1, start the work while working pump (core rod to adjust and gate with pump) working pump at work can't stop. Operating procedures are as follows: Push according to the main pump - depending on the pushing elbow bend option selected speed to feeding, sluice gate, mandrel heated to working temperature began to push push speed adjustable (work) - > push push the machine automatically stops to middle - hydraulic gate lock die mandrel - feeding to loosen the gate back to the finish, gate lock to stem diameter 5 mm began to advance. Note: 1, the main can be used at the same time, when the pump work normally only use a can. Also can be used as a back without stop. 2, backward pump cannot be used at the same time, can only start one, the other a backup. 3, the feeding pump can be used only at the time of loading. 4, the main oil pump hydraulic system safety pressure as 25 mpa, attached to the cylinder of hydraulic system security pressure adjustment for 10 mpa. 5, pushing machine stroke switch installed on both ends of the trip, the actual stroke should be less than the maximum stroke, namely activity before and after the push plate away from the actual endpoint on both ends with 50-80 - mm allowance, in order to avoid the oil cylinder piston on both ends of the cylinder to run when the impact cylinder flange, cause equipment damage. (the switch needs to be changed every two months time, in order to protect More than 5, save energy, the device is novel, compact structure, automatic operation, high production efficiency. Adopts hydraulic cylinder to push the raw material, the hydraulic motor drives the rocker arm rotating bending pipe, their stress, bending speed, bending radius, pipe specifications are adjustable, automation control, accurate and reliable, and less manual intervention, save power, low construction investment, high yield, raw material specifications and applicability, etc.

Other supplier products

|

|

Cold drawn three stone machine |

Cold drawing tee cross machine - cangzhou tengda

Cangzhou tengda machinery equipment factory is one of the professional hydraulic equipment manu... |

|

|

Intermediate frequency hydraulic expanding machine |

Cangzhou tengda machinery factory is the most professional hydraulic equipment manufacturers in north China, specializing in the production and man... |

|

|

Steel pipe cold drawing machine |

Cold drawn steel machine is special equipment of cold drawn steel bar. Its a lot of more phyletic, according to the different ways have different t... |

|

|

Steel pipe hydrostatic testing machine |

Hydrostatic testing machine instructions:

1, the preparation before the operation

1) check whether water tank water to fill

(2) check vertica... |

|

|

Cold heat pipe bender |

Cold heat pipe bender it can put the steel pipe, square tube, round tube, copper pipe, aluminum pipe,

Without having to manufacture elbow: save m... |

All supplier products

Same products

|

|

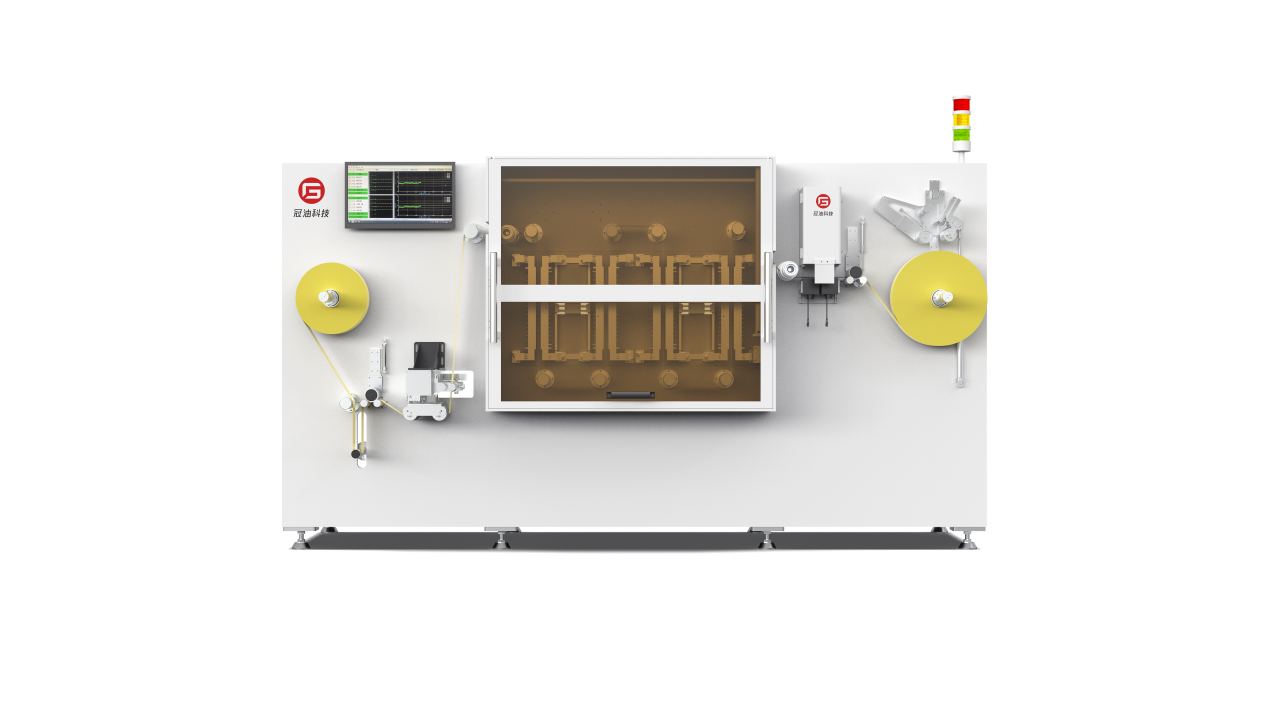

The Single Workstation Electrostatic Perforating Machine |

Seller: Wuhan Guan You Technology Co., Ltd. |

The single workstation electrostatic perforating machineis a professional cigarette paper static ... |

|

|

YZH WHEN1510 Stationary Pedestal Rockbreaker Boom |

Seller: Shandong Yirun Foundation Engineering Co., Ltd |

Below is a detailed introduction to the YZH WHEN1500 fixed hydraulic demolition arm, covering its... |

|

|

YZH WHEN1410 Stationary Pedestal Rockbreaker |

Seller: Shandong Yirun Foundation Engineering Co., Ltd |

YZH WHEN1410 Stationary Pedestal Rockbreaker is a specialized equipment designed for secondary cr... |

|

|

JY-160S2 Standard Plastic Injection Machine |

Seller: Dongguan Jieyang Machinery Co., Ltd |

Straight screw ejected assembly.

Two(three)-phase temperature, ejected speed, backing pressure a... |

|

|

WPC Terrace panel extrusion line |

Seller: Qingdao Trusty Plastic Machinery Co.,Ltd |

Wood-polymer composite (WPC), unlike wood, has higher resistance to aggressive environments and v... |